Re: Pros And Cons Of Using Double Take Up Pulley Arrangement?

I moved your post to a more appropriate section than general aspects.

There are no technical issues associated with dual take-up pulleys but there are maintenance issues in making sure the belt tracks properly through the multiple pulleys required for this type of take-up.

The other major consideration is lifting the counterweight (normally 2 times the single take-up weight) in order to create zero energy prior to doing any maintenance on the belt. Simply locking out the electrical starter does not eliminate the energy stored in the belt from the counterweight.

You would be wise to install a system to lift the take-up and pin it into a fixed maintenance position than to try and lift it with a crane. We had a system like this and that was the biggest complaint from the maintenance was having to lift that huge mass if they had to do any maintenance on the belt. It took longer to rig up for the lift than it did to do the maintenance. ■

Gary Blenkhorn

President - Bulk Handlng Technology Inc.

Email: garyblenkhorn@gmail.com

Linkedin Profile: http://www.linkedin.com/in/gary-blenkhorn-6286954b

Offering Conveyor Design Services, Conveyor Transfer Design Services and SolidWorks Design Services for equipment layouts.

Dual Gravity Take-Ups

========================================================

CEMA is referring to gravity take-up (GTU) placed apart with separate take-up masses with independent motions. CEMA is wrong to state they cannot function correctly, when you know the purpose and are able to deal with the design complications. By one example, the analogy of up-hill and downhill terrain, with GTUP placed either side of the drive station can lower the required belt tension and rating. It is not appropriate to go through details here that list all conditions that need to be covered. La Coipa OLC, many years ago in Chile, was designed with such a system using one counterweight mass with two independent GTUP pulleys. It worked well.

CEMA was warning against placing two GTUP stations that functionally displacement/accumulate belt, when they act independent for one-another. Here they are correct. In such a case, only one acts and the other needs twice the displacement to deal with the variation in belt tensions at the two locations. As with the note above, with the proper design they work. I witnessed one such bo0-boo in South Africa, where the designer did not understand this and cause great grief when it came to commissioning.

For your gravity take-up configuration, Gary has given the answer. ■

Re: Pros And Cons Of Using Double Take Up Pulley Arrangement?

Thanks for the guidance!

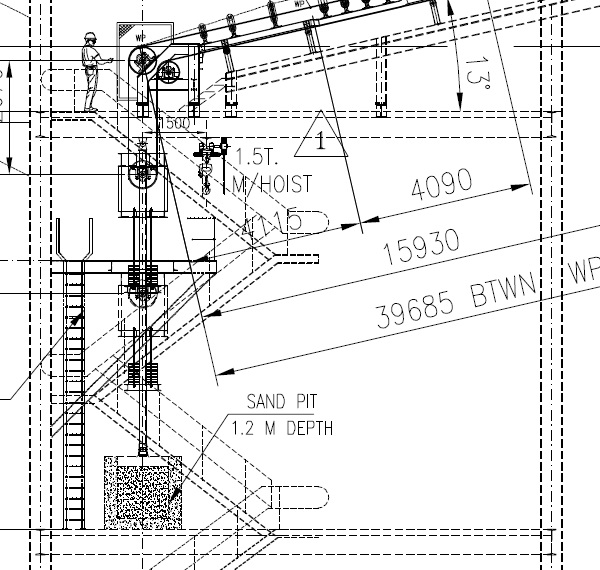

Further to this, is it a wise practice to attach the vertical gravity take up at the tail end of the conveyor? Sketch attached for reference.

href="https://forum.bulk-online.com/attachment.php?attachmentid=44050&d=1433000963" id="attachment44050" rel="Lightbox86078" target="blank">■

Tail Gtup

========================

We often do so to better control elastic shock waves on incline conveyors. Better mutes the tensile and compression shockwaves when motor power is cut. ■

Re: Pros And Cons Of Using Double Take Up Pulley Arrangement?

Dear Sir,

Is there any formula to work out the impact load exerted by the counter weight assembly (including the take up pulley) when the belt snaps (Referring to the sketch attached in previous thread)? This is required as in many cases, the sand pit (on to which the counter weight assembly falls) is on the junction tower floors (esp for tripper conveyors (sketch attached). As per the theories related to strain energy and impact loading, Impact force= Falling weight x stopping distance/ height of fall. Also we can work out impact stress(= x √(1+h/∆)). But my question is how can we exactly work out the impact load acting on the floor beams when the counter weight assembly falls. ■

A Miss Is As Good As 1.625 Kilometrres.

The arrangement illustrated has 2 superfluous bend pulleys and a whole lot of complicated steelwork. I presented hereabouts a design where any counterwieght could be set to any height and lowered to ground as fast as the winch winder could cover the distance. All this from a pair of sheaves. Replies all pointed to the belief that the system was undesireable for one senseless reason or another. So it remains almost forgotten until I read about difficulties that need not be there.

Just console yourself that your presented system was almost there...almost. ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Re: Pros And Cons Of Using Double Take Up Pulley Arrangement?

CEMA is referring to gravity take-up (GTU) placed apart with separate take-up masses with independent motions. CEMA is wrong to state they cannot function correctly, when you know the purpose and are able to deal with the design complications. By one example, the analogy of up-hill and downhill terrain, with GTUP placed either side of the drive station can lower the required belt tension and rating. It is not appropriate to go through details here that list all conditions that need to be covered. La Coipa OLC, many years ago in Chile, was designed with such a system using one counterweight mass with two independent GTUP pulleys. It worked well.

CEMA was warning against placing two GTUP stations that functionally displacement/accumulate belt, when they act independent for one-another. Here they are correct. In such a case, only one acts and the other needs twice the displacement to deal with the variation in belt tensions at the two locations. As with the note above, with the proper design they work. I witnessed one such bo0-boo in South Africa, where the designer did not understand this and cause great grief when it came to commissioning.

For your gravity take-up configuration, Gary has given the answer.

Thank you Mr.Nordell for sharing your knowledge.

We would be thankful, if you post how the problem in South Africa was solved, when two independent gravity take-ups were installed in a single conveyor.

Thanks a lot & high regards to all.

S.Ganesh ■

Couple Of Sheaves

Just console yourself that your presented system was almost there...almost.

========================================

I understand your approach. Today we do it with a powered winch. Manual is OK just slow. ■

Re: Pros And Cons Of Using Double Take Up Pulley Arrangement?

As suggested (?) originally, although obviously only a guess, I propose this was to reduce the take up mass travel.

Regarding the maintenance concerns, options may include:

1. Suitable access: to [walkways, self closing gates [and perhaps locking] etc], and on; the take up mass.

2. A winch that can be used to adjust the take up mass [it "can" be done with VTUPs, despite that it, like almost everything, has its own issues].

The following may be of interest regarding conveyors that have more than one take up:

http://www.saimh.co.za/beltcon/beltcon9/paper911.html

Regards,

Lyle ■

Pros and cons of using double take up pulley arrangement?

Recently in one of our projects, we used double take up pulley arrangement as a part of VGTU (vertical gravity take up unit) as shown in the attached sketch. Single counter weight frame was attached to two take up pulleys for tensioning. Even though for attaining the same slack side tension, we have to use more counter weights compared to single take up pulley arrangement, this arrangement seems to be better than HGTU (Horizontal gravity take up) where the space available for take up travel is less. The conveyor is now under operation and appears to be smooth. Is there any technical issue in the arrangement adopted? The doubt cropped up in my mind because, CEMA says “two automatic takeups cannot function properly on the same conveyor”.

Attachments

tempJPEG:forum_attachments/file_container/temp_2.jpg (BMP)

■