Re: Feeding System For An Aluminum Furnace

The material to be fed using this system is :

Bales of Al-chip: one bale=30kg and size 280 mm x 300 mm x 270 mm

Al pipe bundle: 30 kg bundle

Ingots

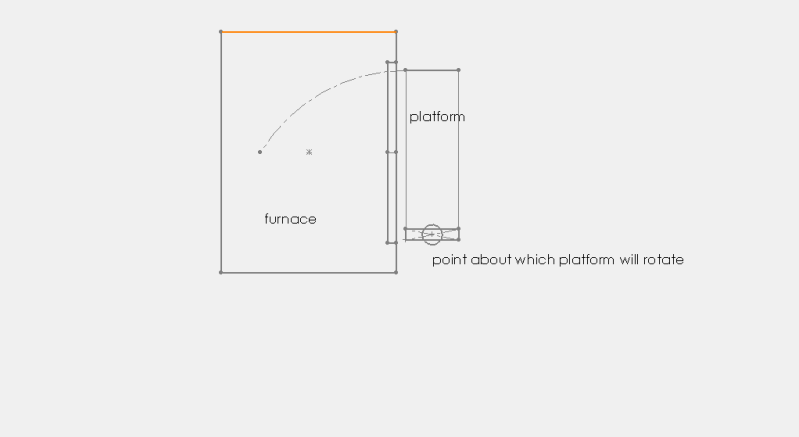

Here is the rough sketch that would help visualize things a bit. It's a top view

We are designing the system so that 1 ton can be fed immediately. ■

Feeder

I'd consider a ladle-like action principle too, with rotation along the longitudinal axis. As i understand you want to make a trapdoor, with actioning of trapdoor within the furnace. This would mean mechanics put in a rough environment, a quite sudden drop & splash and always the possibility of a "trapped" trapdoor (seen that the fed materials may be cumbersome and unwieldy).

Regards

R. ■

Chute Design Again

Yes: I did write 'chute'.

No: It won't work because material is hitting the wall too soon. Because of the nearby molten sink the material will hang against the wall and prevent retraction of the chute. ■

???

Where does it write "chute", and what is it that won' work? Please comment.

Thank you!

Regards

R. ■

Re: Feeding System For An Aluminum Furnace

Regards

R.

Thanks for your comments Roland. You are right about laddle like rotation however, considering there is enormous load that would need to be rotated, the gravity drop seems to be best solution avoiding any complications. The furnace floor isn't too deep and the factory we are doing for says the height is not that much for dropped materials to damage the floor. ■

Re: Feeding System For An Aluminum Furnace

The scrap needs to be contained on all 4 sides or else it will fall off the platform, maybe, most probably against the door. The sketch provided shows it.

Then the scrap slides out of the 4 sided container, chute, and bangs into the far wall on some occasions.

Flow from the chute stops.

Because it is intended to melt: the scrap ought to begin melting while it cannot move.

Likely the melted or softened material has lodged against the chute top edge.

Since the chute must be on the decline...to promote sliding even ...then any attempt to raise the chute clear will compress the residual scrap between the lip and the furnace sidewall.

I'd make the table/chute whatever from aluminium so that when it melts it won't contaminate the batch. ■

Re: Feeding System For An Aluminum Furnace

Apparently the material is in bundles form. The chips are pressed to bales of about 30 kilograms, the pipes are thrown in bundles and ingots are worth 30 kilograms each as well. So material cannot flow to fall from aside. All of it is in bulky units placed on a mesh type floor attached to cantilever beam which can rotate about one end and is locked at the other (the locking mechanism is being pondered). You open the lock, the mesh like floor opens allowing material placed over it to fall down. There is ample room below to make the mesh floor hang and then be returned to original position ■

Charging _ P - T

Dear FaisalMasud,

Attachment 31008

this is a open hearth furnace charging crane, which inserts its arm into a connecting head of a charging ladle / container, then moves to the furnace, inserts the ladle / container into the furnace and rotates that container etc. The charging ladle / container is an autonomous unit with foursided deep dumper body, the charging crane (read mobile unit as per requirement) may use several of these to be refilled when not on the crane. Further info is available from internet etc.

Regards

R. ■

Re: Feeding System For An Aluminum Furnace

Dear Roland,

Thanks a lot for this solution. I am looking into this too as an option. Infact our current thought solutions resemble this one as well.

I would like to show you a furnace resembling the one we are going to design for. It's here:

http://superfurnace.auto.officelive....pimage002.jpg

The base of the door is 80cm above the factory floor. The door is about 9ft wide and 40 inches high. The furnace itself is 11 ft deep horizontally.

I am new to this field so I wanted to ask people here do we have any codes/standards for designing these bulk charging systems like ASME boiler code etc? ■

Feeding System for an Aluminum Furnace

Designing a Feeding System for Aluminum Furnace

Hello all,

I am working on making a feeding system for aluminum furnace which would feed ingots, Al chip bales and cut pipes all at once. We have already brainstormed and developed possible solutions. One such solution we have thought of is a rotating platform that is as long as the furnace's door (10 feet wide) and is rotated into the furnace (which extends 11 ft inwards) and then material to be fed is dropped under action of gravity as the "floor" holding it is unlocked. Hoping you get what I mean, I wanted to ask do such solutions exist before ? Also I would like experts here to comment on our this approach towards feeding the material.

It would be also much appreciated if you people can suggest me some standard text and codes for designing such equipment. ■