VibraFloorsearch?q=VibraFloor+site:bulk online.com has a revolutionary technology for reclaiming flakes, soya bean meal, DDGS, grain, pulses, fertiliser, sugar and many other products that you may be very interested in.

The main advantages are the complete silo clearance, lack of routine maintenance, and no degradation of fragile product such as flakes, basmati rice and pop corn.

The main benefits the systems are as follows:

- No routine maintenance

- No bridging or blocking

- Guaranteed total silo clearance

- No Product degradation

- No Dust generation

- High discharge rate

- In built system redundancy

- No major rotating or wearing parts

- No stack height limit (up to 220t/m2)

- Completely automatic operation

- No vibration or stress transfer to structure

- Very low energy usage

- 20yr proven history

- Can be retrofitted

VibraFloor1375 vibrafloor.htm gets completely away from the need for elaborate and temperamental engineering solutions for both unloading bulk materials or as a fully controllable feed system, to provide a constant flow of material, without experiencing surges, product degradation, and bridging, packing or creating dust.

It works by instigating a wave in the surface plate, which undermines and collapses the leading edge of the stored material through a low pressure zone, creating a progressive avalanche of material before sweeping it away, hence the remarkable energy efficiency of the system (50W per m2 of active floor).

The system will achieve 100% clearance, without human intervention, and avoids placing the storage structure under any pressure or stress. Unlike traditional technologies, where in the event of blockage the feed system continues to pack material behind the blockage, exaggerating the problem; VibraFloorsearch?q=VibraFloor+site:bulk online.com&source=lnms&tbm=isch undermines obstructions and fragments cohesive materials, allowing them to flow through the low pressure zone created at the leading edge of the floor.

Uninterrupted operation of any plant is essential if it is to run efficiently. Unlike traditional technologies, which suffer inevitable breakdowns as a result of complex equipment with numerous moving and wearing parts, VibraFloor requires no routine maintenance as it has no major rotating parts and as a result suffers minimal wear. In the unlikely event that a vibrator motor does fail, the modular system will continue to run, emptying the remainder of the floor, allowing planned maintenance to quickly resolve the problem.

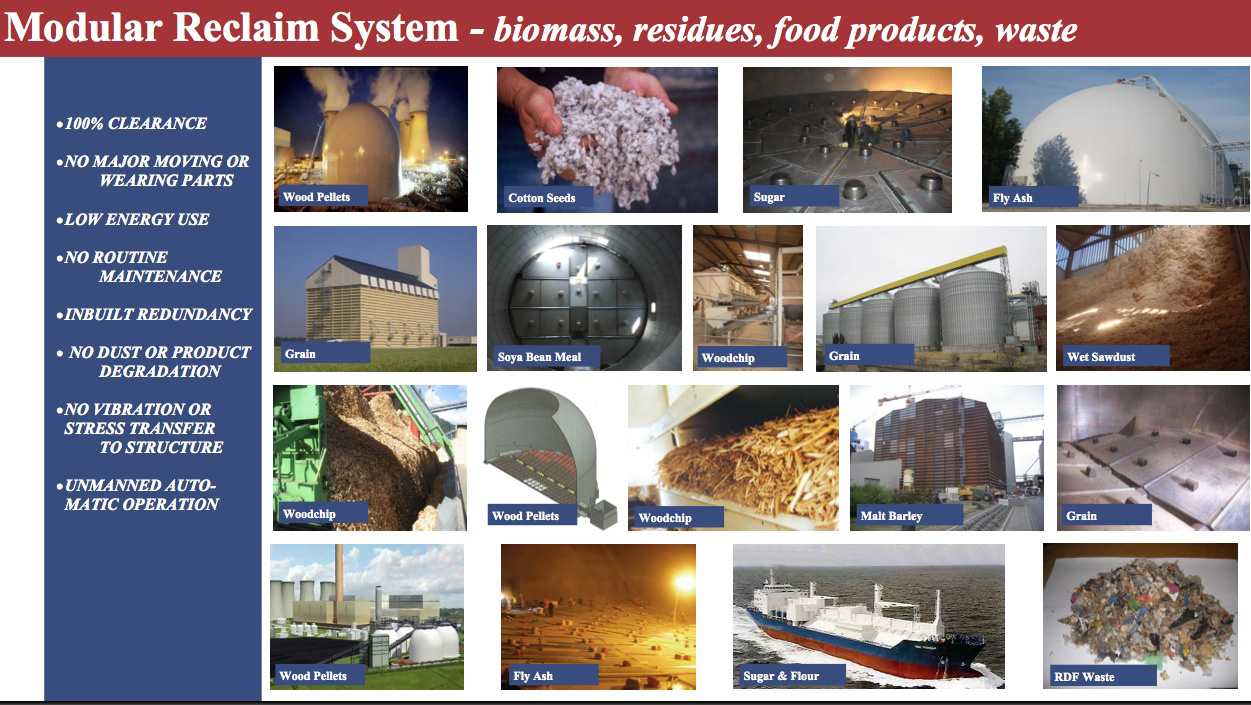

VibraFloor Modular Reclaim System

VibraFloor Modular Reclaim System

VibraFloorsearch?q=VibraFloor+site:bulk online.com has a revolutionary technology for reclaiming flakes, soya bean meal, DDGS, grain, pulses, fertiliser, sugar and many other products that you may be very interested in.

The main advantages are the complete silo clearance, lack of routine maintenance, and no degradation of fragile product such as flakes, basmati rice and pop corn.

The main benefits the systems are as follows:

- No routine maintenance

- No bridging or blocking

- Guaranteed total silo clearance

- No Product degradation

- No Dust generation

- High discharge rate

- In built system redundancy

- No major rotating or wearing parts

- No stack height limit (up to 220t/m2)

- Completely automatic operation

- No vibration or stress transfer to structure

- Very low energy usage

- 20yr proven history

- Can be retrofitted

VibraFloor1375 vibrafloor.htm gets completely away from the need for elaborate and temperamental engineering solutions for both unloading bulk materials or as a fully controllable feed system, to provide a constant flow of material, without experiencing surges, product degradation, and bridging, packing or creating dust.

It works by instigating a wave in the surface plate, which undermines and collapses the leading edge of the stored material through a low pressure zone, creating a progressive avalanche of material before sweeping it away, hence the remarkable energy efficiency of the system (50W per m2 of active floor).

The system will achieve 100% clearance, without human intervention, and avoids placing the storage structure under any pressure or stress. Unlike traditional technologies, where in the event of blockage the feed system continues to pack material behind the blockage, exaggerating the problem; VibraFloorsearch?q=VibraFloor+site:bulk online.com&source=lnms&tbm=isch undermines obstructions and fragments cohesive materials, allowing them to flow through the low pressure zone created at the leading edge of the floor.

Uninterrupted operation of any plant is essential if it is to run efficiently. Unlike traditional technologies, which suffer inevitable breakdowns as a result of complex equipment with numerous moving and wearing parts, VibraFloor requires no routine maintenance as it has no major rotating parts and as a result suffers minimal wear. In the unlikely event that a vibrator motor does fail, the modular system will continue to run, emptying the remainder of the floor, allowing planned maintenance to quickly resolve the problem.

Please watch this Video on a Soya Bean Meal Reclaim System.vibrafloor reclaim system for soya bean meal cold in a 10 6 m silo.html

More information on VibraFloor1375 vibrafloor.htm

Google Search - Websearch?q=VibraFloor+site:bulk online.com

Google Search - Imagessearch?q=VibraFloor+site:bulk online.com&source=lnms&tbm=isch

VibraFloor on the Portalsearch?q=VibraFloor

VibraFloor Video on a Soya Bean Meal Reclaim Systemvibrafloor reclaim system for soya bean meal cold in a 10 6 m silo.html ■