Maintaining the quality and consistency of ingredients while in transit through a factory environment is vital to ensure that the end product is in mint condition for packaging and distribution, which is why a leading hot beverages supplier turned to a conveying system from Spiroflow8623 spiroflow.htm.

The company, which packs instant, roast and ground coffee for most of the major high street chains, required a conveyor which streamlined the transportation process and ensured the minimum degradation of product.

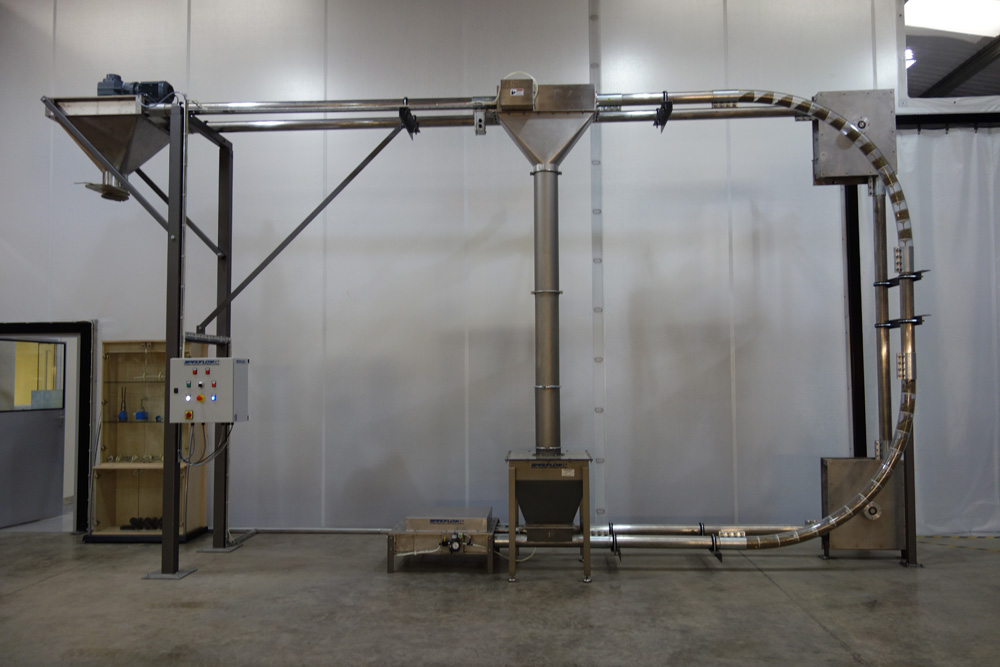

After taking advantage of Spiroflowsearch?q=Spiroflow’s state-of-the-art testing facility at Clitheroe to trial the equipment prior to purchase, the customer then installed a Cableflow® Cable Driven Tubular Drag Conveyor in a z-shaped unit fed through a bulk bag. To meet requirements the system also incorporated a horizontal plane, rather than a vertical one, to maximise floor space at the plant.

Whether transporting powders, granules or whole coffee beans, Cableflow® conveyors are designed for gentle handling and can safely transfer delicate bulk products from single or multiple in-feed points to single or multiple discharge points without any discernible damage.

Manufactured in carbon or stainless steel depending on the customer’s requirements, Cableflow® Cable Driven Tubular Drag Conveyors have been developed from Spiroflow’s Aero Mechanical range, which drags the ingredients along the inside of a tube to facilitate an efficient, dust-tight operation.

Spiroflow’s After Sales Manager, Jeannette Carter, said: “Our customer wanted gentle, time-saving conveying equipment that would maximise production. The Cableflow® conveyor has been designed with gentle handling in mind and has helped reduce manual handling and degradation of the product during the process.”

Cableflow® Cable Driven Tubular Drag Conveyor

in a z-shaped unit fed through a bulk bag

Because the tubular drag conveyors are derived from Spiroflow’s Aero-Mechanical Conveyors, they also enjoy the option to have the patented DART (Dynamic Automatic Rope Tensioner) rope tensioning system for maximum rope life and minimum maintenance. This is a key advantage over competitors’ cable driven conveyors.

Flexibility and totally secure handling are required from conveying equipment if coffee materials have to travel dust-free over long distances and complex routes within an operating plant. Spiroflow, world-leading manufacturer of ATEX approved conveying and bulk handling systems, is renowned for solutions that meet the most rigorous standards in hygiene and containment.

Spiroflow’s Cableflow® system can handle hot, cold, wet, dry, hygroscopic or temperature sensitive materials and is the only mechanical conveyor that can operate in three planes, enabling complex circuits, eliminating transfer points and using only a single drive.

When it comes to the challenges of transporting coffee - whether in powder form, granule or bean - Spiroflow aims to provide the beverages sector the best solution for maintaining product integrity.

In addition to Tubular Cable and Chain Drag Conveyors, Spiroflow is also a manufacturer of Bulk Bag Fillers, Flexible Screw Conveyors, Aero Mechanical Conveyors, Bin Activators, Vacuum Conveyors, Bulk Bag Dischargers, Ingredients Handling and Weighing Systems. The company’s technical and engineering expertise has led to it developing an international reputation for an unrivalled range of products with state-of-the-art control systems.

Background

From early beginnings supplying flexible screw conveyors primarily to the plastics industry, Spiroflowsearch?q=Spiroflow+site:bulk online.com&safe=active&client=safari&rls=en&source=lnms&tbm=isch is today one of the world's leading manufacturers of a full range of equipment for handling dry bulk solids and ingredients in powder, granule, pellet and flake form across the whole spectrum of process industries, boasting household name manufacturers and distributors among its clients.

Spiroflowsearch?client=safari&rls=en&q=Spiroflow+site:bulk online.com conveying and weighing systems are in operation worldwide and are acclaimed for their outstanding versatility and prolonged working life in the most demanding environments. In food and pharmaceuticals, cosmetics and chemicals, minerals and plastics, Spiroflow's experience and proven capability is providing the answer to every conceivable handling need.

Behind all Spiroflowsearch?q=Spiroflow+site:bulk online.com&safe=active&client=safari&rls=en&source=lnms&tbm=isch products is a dedicated design, manufacturing, testing and installation facility, backed up by a rapid spares and service network. High standards are sustained through an on-going development programme utilising CAD design facilities and material testing procedures. Conveying and weighing systems are designed with a minimum of working parts for maximum reliability in operation.

A cornerstone of the company’s success is its eagerness to design and develop bespoke equipment to meet the needs of individual customers.

Spiroflow: Cableflow® Cable Driven Tubular Drag Conveyor

SPIROFLOW’S CONVEYING EQUIPMENT ENSURES INSTANT (COFFEE) BENEFITS

Maintaining the quality and consistency of ingredients while in transit through a factory environment is vital to ensure that the end product is in mint condition for packaging and distribution, which is why a leading hot beverages supplier turned to a conveying system from Spiroflow8623 spiroflow.htm.

The company, which packs instant, roast and ground coffee for most of the major high street chains, required a conveyor which streamlined the transportation process and ensured the minimum degradation of product.

After taking advantage of Spiroflowsearch?q=Spiroflow’s state-of-the-art testing facility at Clitheroe to trial the equipment prior to purchase, the customer then installed a Cableflow® Cable Driven Tubular Drag Conveyor in a z-shaped unit fed through a bulk bag. To meet requirements the system also incorporated a horizontal plane, rather than a vertical one, to maximise floor space at the plant.

Whether transporting powders, granules or whole coffee beans, Cableflow® conveyors are designed for gentle handling and can safely transfer delicate bulk products from single or multiple in-feed points to single or multiple discharge points without any discernible damage.

Manufactured in carbon or stainless steel depending on the customer’s requirements, Cableflow® Cable Driven Tubular Drag Conveyors have been developed from Spiroflow’s Aero Mechanical range, which drags the ingredients along the inside of a tube to facilitate an efficient, dust-tight operation.

Spiroflow’s After Sales Manager, Jeannette Carter, said: “Our customer wanted gentle, time-saving conveying equipment that would maximise production. The Cableflow® conveyor has been designed with gentle handling in mind and has helped reduce manual handling and degradation of the product during the process.”

Cableflow® Cable Driven Tubular Drag Conveyor

in a z-shaped unit fed through a bulk bag

Because the tubular drag conveyors are derived from Spiroflow’s Aero-Mechanical Conveyors, they also enjoy the option to have the patented DART (Dynamic Automatic Rope Tensioner) rope tensioning system for maximum rope life and minimum maintenance. This is a key advantage over competitors’ cable driven conveyors.

Flexibility and totally secure handling are required from conveying equipment if coffee materials have to travel dust-free over long distances and complex routes within an operating plant. Spiroflow, world-leading manufacturer of ATEX approved conveying and bulk handling systems, is renowned for solutions that meet the most rigorous standards in hygiene and containment.

Spiroflow’s Cableflow® system can handle hot, cold, wet, dry, hygroscopic or temperature sensitive materials and is the only mechanical conveyor that can operate in three planes, enabling complex circuits, eliminating transfer points and using only a single drive.

When it comes to the challenges of transporting coffee - whether in powder form, granule or bean - Spiroflow aims to provide the beverages sector the best solution for maintaining product integrity.

In addition to Tubular Cable and Chain Drag Conveyors, Spiroflow is also a manufacturer of Bulk Bag Fillers, Flexible Screw Conveyors, Aero Mechanical Conveyors, Bin Activators, Vacuum Conveyors, Bulk Bag Dischargers, Ingredients Handling and Weighing Systems. The company’s technical and engineering expertise has led to it developing an international reputation for an unrivalled range of products with state-of-the-art control systems.

Background

From early beginnings supplying flexible screw conveyors primarily to the plastics industry, Spiroflowsearch?q=Spiroflow+site:bulk online.com&safe=active&client=safari&rls=en&source=lnms&tbm=isch is today one of the world's leading manufacturers of a full range of equipment for handling dry bulk solids and ingredients in powder, granule, pellet and flake form across the whole spectrum of process industries, boasting household name manufacturers and distributors among its clients.

Spiroflowsearch?client=safari&rls=en&q=Spiroflow+site:bulk online.com conveying and weighing systems are in operation worldwide and are acclaimed for their outstanding versatility and prolonged working life in the most demanding environments. In food and pharmaceuticals, cosmetics and chemicals, minerals and plastics, Spiroflow's experience and proven capability is providing the answer to every conceivable handling need.

Behind all Spiroflowsearch?q=Spiroflow+site:bulk online.com&safe=active&client=safari&rls=en&source=lnms&tbm=isch products is a dedicated design, manufacturing, testing and installation facility, backed up by a rapid spares and service network. High standards are sustained through an on-going development programme utilising CAD design facilities and material testing procedures. Conveying and weighing systems are designed with a minimum of working parts for maximum reliability in operation.

A cornerstone of the company’s success is its eagerness to design and develop bespoke equipment to meet the needs of individual customers.

More information on Spiroflow8623 spiroflow.htm

Google Search - Websearch?client=safari&rls=en&q=Spiroflow+site:bulk online.com

Google Search - Imagessearch?q=Spiroflow+site:bulk online.com&safe=active&client=safari&rls=en&source=lnms&tbm=isch

Spiroflow on the Portalsearch?q=Spiroflow ■