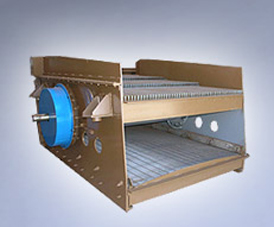

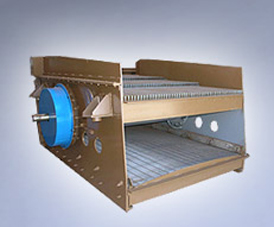

Slipstick Horizontal Motion Conveyor

The most productive advancement in horizontal conveying equipment in decades, the Slipstick® horizontal motion conveyor is recognized for its gentle, non-impact conveying motion and enviable record of low maintenance, high reliability performance.

Highly effective for conveying detergents and granulated products, the Slipstick’s gentle horizontal, slow-advance, quick-return motion practically eliminates conveyor-imposed product damage while ensuring a very high level of sanitation.

Additional benefits include:

Elimination of material damage and compacting

Simple construction for ease of cleaning

Long-term reliable performance

How it works

Unlike conventional vibrating conveyors that use a vertical pitching motion to propel material with repeated impacts which can cause product breakdown, the Slipstick employs a single-drive mechanism to move the product. This mechanism provides a unique horizontal differential motion which glides the product down the pan. The consistent conveying motion throughout the length, width, and depth of the product bed helps prevent sticky build-up. And because it isn’t dependent on impact to provide motion, the Slipstick conveys deep product beds uniformly, with no stratification.

Variety of Configurations

Built in lengths from 4 feet to more than 200 feet, the Slipstick offers a variable rate of product delivery depending upon the application, and can be adjusted to suit most any requirement.

The Slipstick can be suspended from overhead to maximize the use of valuable floorspace or built with floor-mounted pedestals. Because it is dynamically self-balancing, no counterweights or heavy isolation bases are necessary. The drive module can be mounted at either end or below the conveyor’s pan section.

Pan options for the Slipstick include multiple channels, pneumatic discharge gates, and removable covers. Sealed tube sections provide added product protection and allow for CIP. The Slipstick can also be configured to align, singulate, divide, dry, or cool product as it flows through the conveyor.

Triple/S Dynamics offers full turn-key conveying systems which enable us to provide your company with a single-source supplier for any material handling need. When coupled with your preferred vendors, we can supply a complete package that integrates our material handling equipment with other processing or packaging equipment.

Ease of Maintenance

The Slipstick is designed for long, trouble-free service life. Mechanically, it’s based on a minimum of moving parts, with the fully enclosed drive mechanism consisting only of bearing-mounted, gear-coupled shafts. Durability is ensured through our dedication to solid construction throughout.

Long Life

With more than 1,000 Slipstick conveyors in use today, you can be sure of decades of reliable service. The Slipstick’s enviable record of uptime solidifies its reputation for reliability, even in the harshest of environments.

Advantages of Horizontal-Motion Conveyors

The horizontal-motion conveyor offers a number of advantages over the conventional vibrating conveyors, screw conveyors, and drag conveyors that are often used in bulk-handling applications. Compared with conventional vibrating conveyors, which are usually powered by springs and convey material through impact, the horizontal-motion conveyor provides gentle and sanitary transportation of fragile materials such as food products, agglomerated powders, and extruded, flaked, or pelletized products.

For more information, please visit:

https://edir.bulk-online.com/profile...s-dynamics.htm

http://www.google.de/search?client=s...CJSeAap1PGjAQ ■

Vibrating Conveyors

When you need a quiet, clean, low-maintenance conveyor for moving free-flowing solids, vibrating conveyors from Triple/S Dynamics are the ideal choice. These efficient conveyors are designed to provide material travel rates ranging from just a few feet per minute to over 100 feet per minute.

Triple/S vibratory conveyors are designed and balanced so that they transmit very little dynamic load to supporting members, and may be operated under continuous duty for years with very little maintenance.

Triple/S Dynamics vibrating conveyors feature a variety of drive and suspension arrangements, according to need. A custom combination of the best conveyor features for each application can be assembled for any application. In addition, vibrating conveyors can be designed to integrate one of more process steps into a single machine.

Application Bulletin Brochure

For more information, please visit:

https://edir.bulk-online.com/profile...s-dynamics.htm

http://www.google.de/search?client=s...CJSeAap1PGjAQ ■

Triple/S Dynamics

Screening Strategies™

At the Leading Edge of Screening Technology

DON’T KNOW MUCH ABOUT SCREENING?

Not to Worry….Just call or e-mail Screening Strategies and let us know what you want to do. We’ll ask for the information we need to make a GUARANTEED PERFORMANCE Proposal based on more than 120 years of experience in bulk material separations. You'll be reassured to know we don't take chances -- if we’re not sure, we’ll ask for a sample for evaluation in our Separations Laboratory, and you will be welcome to observe our procedures.

Screening Strategies is a division of Triple/S Dynamics, Inc. Our products are OVERSTROM® High-Speed Vibrating Screens, TEXAS SHAKER® Precision Screeners, and ROTASCREEN® Trommels.

WE SELL RESULTS. We understand that from the process engineer’s point of view, screening is only one unit operation among many in his process, and although important, probably is not the most complex. We understand that he doesn’t necessarily care about how his screening machine works, provided that it is “user-friendly” and performs its required role consistently and constantly and without interruption for maintenance and repair. This is our goal, in design, manufacture, and application. It is what “Quality” means to us.

For more information, please visit:

href="https://edir.bulk-online.com/profile/620-triple-s-dynamics.htm" target="blank">https://edir.bulk-online.com/profile...s-dynamics.htm

href="http://www.google.de/search?hl=de&client=safari&rls=en&q=Triple%2FS+site%3Abulk-online.com&btnG=Suche&meta=&aq=f&aqi=&aql=&oq=&gsrfai=" target="blank">http://www.google.de/search?hl=de&cl...=&oq=&gsrfai=

Fig. 1: OVERSTROM® washing and dewatering screen with 2-bearing all lubricated CV (centroidal) vibrator has 3 staged grizzly panels over side-tensioned bottom screen

Fig. 2: OVERSTROM® Horizontal High-Speed vibrating screens with 4-bearing all lubricated vibrator modules are available in sizes from 3 ft. x 6 ft. to 8 ft. x 20 ft.,open or enclosed construction

Fig. 3: Inclines, OHV (overhead vibrator) OVERSTROM® Horizontal High-Speed vibrating screen, with 2-bearing all lubricated vibrator module, is equipped a flat, stepped polyurethane screen deck. Sizes range from 2 ft. x 4 ft. to 8 ft x 20 ft.

Attachments

■

Trommels

Screening Strategies, a division of Triple/S Dynamics

ROTASCREEN® Trommels

ROTASCREEN® Trommels serve a limited range of applications that vibrating or oscillating screens can’t handle. They may be used in resource recovery to segregate solid waste in various forms including MSW (garbage), compost, incinerator ash and construction debris, or in mining and aggregate operations for scrubbing rock and sand. Cost per ton-hour of capacity is high, compared with conventional screening machines. Screening drum diameters range from 4’ to 10’, and lengths from 6’ to 70’. Distinguished from low-end standardized designs, each ROTASCREEN is customized to its application, choosing from a variety of options in construction and power transmission.

For more information, please visit:

href="https://edir.bulk-online.com/profile/620-triple-s-dynamics.htm" target="blank">https://edir.bulk-online.com/profile...s-dynamics.htm

href="http://www.google.de/search?hl=de&client=safari&rls=en&q=Triple%2FS+site%3Abulk-online.com&btnG=Suche&meta=&aq=f&aqi=&aql=&oq=&gsrfai=" target="blank">http://www.google.de/search?hl=de&cl...=&oq=&gsrfai=

Fig. 1: Roundness and concentricity are the hallmarks of quality in ROTASCREEN® Trommel construction. Frtom ring forged riding rings to alloy steel trunnion wheels, the smooth-running ROTASCREEN® is built to last.

Fig. 2: This sand washing ROTASCREEN® trommel, with modular urethane screen panels, resists abrasive wear with a friction drive using urethane-tired trunnion wheels against a ring-forged steel riding ring.

Attachments

■

Triple/S Dynamics

Screening Strategies, a division of Triple/S Dynamics

Overstrom High-Speed Vibrating Screens

Overstrom® High-Speed Vibrating Screens come in a bewildering variety of models, sizes, configurations and accessories for wet and dry screening, too many for cataloguing. If a high-speed vibrating screen is the right choice, we’ll recommend what we think is the best combination for your purpose. It may be inclined or horizontal, open or enclosed, customized with your choices from an endless variety of screen media and accessories. Speeds and amplitudes will be optimized for your application, within a range of 0.100” to .500” total amplitude, at frequencies selected to produce peak acceleration between 4 and 6 g’s. Deck slope, also optimized for your application, will range from 11 deg. to 20 deg. In single, double or triple-deck models, screen sizes go up from 3’x6’ to 8’x 20’.

Overstrom Brochure

For more information, please visit:

https://edir.bulk-online.com/profile...s-dynamics.htm

http://www.google.de/search?client=s...CJSeAap1PGjAQ ■

Product In Feed Distributors

Triple/S Dynamics Product In-Feed Distributors provide food, chemical and pharmaceutical processors an efficient, sanitary means of uniformly distributing free-flowing or non-free-flowing products across the full width of a dryer, cooler, oven or surge bin.

Our proprietary oscillating model traverses the full width of the belt at a constant speed to uniformly distribute product as needed. The reciprocating drive mechanism is available with either a belt or vibratory conveyor for optimal product distribution.

Diagonal Slot Vibratory Distributors are designed for feeding high speed or wide belt applications. They’re available as extended discharge sections of vibratory conveyors or as stand-alone units to deposit product across the full width of a dryer, cooler, oven or surge bin, via a diagonal slot in the conveyor pan.

Triple/S Dynamics distributors are available in stainless steel, aluminum or painted carbon steel. Conveyor pans can also be coated with wear resistant, non-stick coatings. Vibratory distributors are dynamically balanced and tuned to run at natural harmonic frequencies for the optimum in smooth, trouble-free operation.

Other Distributor Configurations

•Reciprocating product spreading rakes

•Rotary wobble-plate spreaders

•Screening & scalping vibratory systems

•Stationary or automatically adjustable plows

•Distribution systems with multiple gates allow products to be directed to various locations

For more information, please visit:

https://edir.bulk-online.com/oldedir...ics-200412.htm

http://www.google.de/search?client=s...CJSeAap1PGjAQ ■

Texas Shaker Screener For The Grain Industry

Screening Strategies, a division of Triple/S Dynamics

Texas Shaker® Screeners

The TEXAS SHAKER® is designed for precision screening and sizing in aperture ranges from ” to 75 microns. Its long stroke, slow-speed horizontal reciprocating motion promotes rapid stratification, and constantly changing velocities yield the highest throughput of undersize per cycle. All models are fully enclosed. Self-cleaning ball decks are standard. The QC models feature two-part screen decks, with independent ball racks and screen frames. Operating parameters for its straight-line horizontal motion are optimized at 1” stroke, 6 deg. deck slope and 475 cpm, producing peak acceleration of 3.2 g. The screen length is fixed at 10 ft., and widths range from 3’ to 8’. Multiple-deck configurations offer up to 1,000 sq. ft. of screen surface, arranged for single, double or three-screen separations.

Texas Shaker Brochure

For more information, please visit:

https://edir.bulk-online.com/profile...s-dynamics.htm

http://www.google.de/search?client=s...CJSeAap1PGjAQ ■

Granulators For Dry Processing

Triple/S Dynamics

Granulators

Triple/S radial-knife granulators are the performance leader in granulating insulated copper, aluminum wire, cable, heavy scrap plastic sections or purgings, as well as chopping a variety of other non-ferrous materials.

Built for durability and reliability, our granulators offer unmatched, heavy-duty construction, greater weight, and higher capacity in continuous-duty operations. All Triple/S models feature a competitive edge: longer rotors with larger cutting circles, thereby increasing the grate area and ultimately improving efficiency. Each model features knives which are designed with a minimum rake angle on the cutting edge to resist chipping and nicking, retaining a sharp edge longer under severe service. And Triple/S granulators use fewer knives than competitive granulators, spanning the full cutting length, thereby reducing the time required for knife changing or re-gapping.

Download the Granulator Brochure.

For more information, please visit:

https://edir.bulk-online.com/profile...s-dynamics.htm

http://www.google.de/search?client=s...CJSeAap1PGjAQ ■

Application Laboratory

Screening Strategies, a division of Triple/S Dynamics

Application Laboratory

Triple/S Dynamics’ Applications and Product Development Laboratory is an important component in the company’s close working relationship with its customers. With a wide range of testing and analysis equipment, this lab enables company applications engineers to test screens, separators, conveyors, shredders and granulators on customers’ products prior to recommendation. The facility is also routinely used to determine optimal equipment size, estimate yield and production scale capacities and to project the final characteristics of the product after screening, separation, shredding or conveying.

Download the Application Laboratory Brochure

To request your material for testing visit our website.

For more information, please visit:

https://edir.bulk-online.com/profile...s-dynamics.htm

http://www.google.de/search?client=s...CJSeAap1PGjAQ ■

Gravity Separators

Triple/S Dynamics

Gravity Separators

Triple/S Gravity Separators use a combination of air flow and vibration to create a separation of materials which have dissimilar densities. Considered the most efficient separators for many dry materials applications, Triple/S gravity separators are highly effective in the following applications:

•Agricultural commodity cleaning

•Reclaiming of applications in materials recycling

•Mineral separations

•Filter media separations

Triple/S Dynamics will assess your requirements and help determine the best separation equipment for your application.

For more information, please visit:

https://edir.bulk-online.com/profile...s-dynamics.htm

http://www.google.de/search?client=s...CJSeAap1PGjAQ ■

Screening Technology Handbook

Screening Strategies, a division of Triple/S Dynamics

Screening Technology Handbook

Our “Screening Technology Handbook” presents detailed information, including empirical methods for estimating screen capacity and the more comprehensive “Screenability” test method practiced in our Separations Laboratory. Complete and submit the form to receive a hard copy of this Handbook.

For more information, please visit:

https://edir.bulk-online.com/profile...s-dynamics.htm

http://www.google.de/search?client=s...CJSeAap1PGjAQ ■

Vibratory Conveyor: Tex Flex

The TEX-FLEX Excited Base Vibratory Conveyor from Triple/S Dynamics utilizes a single maintenance free rotary electric vibrator mounted to an isolated conveyor frame to energize the leaf springs supporting the conveyor pan to produce the maximum conveying action with minimal power requirements. For most applications, the power requirement is less than 1 HP. The rotary electric vibrator is inverter driven allowing easy adjustment of conveyor speed and has adjustable eccentric weights allowing the force output and resulting conveyor stroke to be easily changed in the field to optimize conveying efficiency.

Download the Tex Flex Brochure

For more information, please visit:

https://edir.bulk-online.com/oldedir...ics-200412.htm

http://www.google.de/search?client=s...CJSeAap1PGjAQ ■

Screening Application & Materials

Screening Strategies™

At the Leading Edge of Screening Technology

INDUSTRIES SERVED -SCREENING

Aggregate Mined Products

Cement Minerals

Chemicals Ores

Clay Paper

Coal Pharmaceuticals

Coke Plastics

Dairy Primary Metals

Explosives Recycling

Fertilizers Refractories

Food Rock

Foundry Rubber

Glass Solid Waste

Grains Steel Mills

Gravel Tobacco

Gypsum Wineries

Limestone Wood & Paper

SCREENING APPLICATIONS

Board Plants

Ceramics

Chip Mills

Grain & Vegetable Process Plants

Grain Elevators & Terminals

Malting Plants

Mulch & Bark Mills

Oil Seed Plants

Processed Food Plants

Pulp & Paper Mills

Recycle Plants

Rock

Sand

Saw Mills

Seed Cleaning Plants

Silica

For more information, please visit:

https://edir.bulk-online.com/profile...s-dynamics.htm

http://www.google.de/search?client=s...CJSeAap1PGjAQ ■

Technical Information Center: Video

Triple/S Dynamics

Technical Information Center: Video

Recently, Triple/S Dynamics created a YouTube channel. This makes it easier for customers to watch and get updated on any new videos without having to do a search. As a subscriber, you will be the first to receive updates on videos posted by our team. Currently videos are posted on the Slipstick. Screening and granulating videos will be posted through out the year. Be the first to know! Become a Triple/S Dynamics YouTube Subscriber.

For more information, please visit:

https://edir.bulk-online.com/profile...s-dynamics.htm

http://www.google.de/search?client=s...CJSeAap1PGjAQ ■

Screening Strategies: Square Wire Mesh Cloth Specs

Screening Strategies

Square Wire Mesh Cloth Specifications

Steel, Stainless Steel, Phosphor Bronze, Bronze, Brass, Copper, Aluminum, Monel and Nickel

Download your copy!

For more information, please visit:

https://edir.bulk-online.com/profile...s-dynamics.htm

http://www.google.de/search?client=s...CJSeAap1PGjAQ ■

Slipstick Design Guide Available

Dallas, Texas - Triple/S Dynamics, creator of the Slipstick® horizontal motion conveyor, has released a new interactive design guide covering the functions and options of their unique conveying system. The design guide can also be downloaded.

The guide, available in electronic format, allows viewers to navigate through sections covering every aspect of the Slipstick system, from trough covers to industry applications. By simply clicking on the title of the appropriate topic, the file brings up a detailed and colorful page with intricate descriptions of the respective feature.

Within the document, information and drawings are provided on conveyor types, troughs, covers, tube conveyors, X-Force™, support and suspension, gates, screens, applications, order information, and a company overview.

For more information, please visit:

https://edir.bulk-online.com/oldedir...ics-200412.htm

http://www.google.de/search?client=s...CJSeAap1PGjAQ ■

Follow Us!

Come Join Us!

Triple/S Dynamics and Screening Strategies are on Facebook, Twitter, LinkedIn, and YouTube. Please visit our site and join us! You will find regular useful content.

For more information, please visit:

https://edir.bulk-online.com/oldedir...ics-200412.htm

http://www.google.de/search?client=s...CJSeAap1PGjAQ ■

Triple/S Dynamics Parts & Services

Order your Triple/S Dynamic's Equipment Online 24/7!

Order replacement parts for all your conveying systems, processing equipment, separation equipment, and bin fillers manufactured by Triple/S Dynamics. Replacement parts and services are available for all F.E.C. product handling equipment as well. You can order 24/7 online!

In addition to ordering parts & services online, you can now request another copy of your equipment manual online as well. The manuals can be emailed, printed or placed on a cd...your choice! Be sure to fill out the form completely to ensure you will receive the correct manual.

Triple/S Dynamics provides service at our locations or at your facility. Typical service work includes:

* Equipment audits: involve a thorough inspection of the equipment with an on-site description of service requirements the equipment may need to provide more efficient operation or to prevent unexpected downtime.

* Drive rebuild and repair. Where Triple/S service technicians do the work or supervise a separate crew.

* Equipment set-up, installation supervision and commissioning.

To order parts and services or to request a manual visit us online!

For more information, please visit:

https://edir.bulk-online.com/oldedir...ics-200412.htm

http://www.google.de/search?client=s...CJSeAap1PGjAQ ■

Triple/S Dynamics

The leader in conveying systems for more than 120 years.

Triple/S Dynamics is recognized as one of the leading conveyor manufacturers of horizontal motion conveyor systems and screening and separation equipment for a variety of processing industries. Throughout more than 120 years of service, Triple/S has accumulated a depth and breadth of experience that has led to the most rugged, safe, sanitary, and reliable horizontal motion conveyor systems in the industry, an efficient alternative to vibratory conveying systems. We take pride in tailoring solutions to meet the specific needs of each customer, providing the best, most precise match of equipment to application. Industries we serve include mining, food processing, recycling, bulk handling, agriculture, chemical processing, and foundry. With a rich history of innovation, Triple/S Dynamics remains a pioneer in advancing the entire processing industry.

For more information, please visit:

https://edir.bulk-online.com/profile...s-dynamics.htm

http://www.google.de/search?client=s...CJSeAap1PGjAQ

Attachments

slipstick (GIF)

■