Re: Lining Of Iron Ore Chutes

Sorry, there is no answer to this question. Depends on the chute design, material size. material speed through the transfer and the quality of the ceramics

Col Benjamin

Gulf Conveyor Systems P/L ■

Ceramic Lining Of Iron Ore Chutes

Raja,

We have been supplying and fitting 50 thick alumina tiles at blast furnace areas for many years. Some areas are only 25 thick.

In the main impact areas we fit our proprietary Lingrid panels which are bolt on with special shape ceramic inserts.

Mittal Steel in South Africa find this the cost effective solution.

Regards,

Eric Olsen

Lintec Engineering (Pty) Ltd.

South Africa

https://edir.bulk-online.com/profile...ngineering.htm ■

Re: Lining Of Iron Ore Chutes

Dear Sir,

It is true that more information is needed in order to suggest a cost-effective solution. Nevertheless, you can expect longer lasting protection if you choose Ceramic Liners. Depending on the design of your chute, the flow with establish a particular wear pattern and some areas will be more vulnerable than others.

We have serviced several iron ore operations in Australia with good results.

Some properties have 44 mm thick liners with a life expectancy of 17 million tons ( <40 mm and 10,000 TPH), others use 64 mm thick liners with a life expectancy of 1,500,000 tons. In each case a specific application has to be designed. Several considerations need to be taken into account such as: How abrasive is the particular iron ore you process, what crossflow area is available inside each chute (very thick liners on a "thin" chute will last a long time but if high flow rates are demanded, the chute will backflow), what is your average service time, how difficult is it to reach key wear spots inside the chute.

In conclusion, choose your wear liner supplier carefully and have her/him consider all the aspects above and others you consider relevant.

Regards, ■

Re: Lining Of Iron Ore Chutes

The original post begs the question: "Why do you want to use alumina ceramics?"

Particularly since you seem to have no performance information to back your decision. ■

Re: Lining Of Iron Ore Chutes

Hallo Raja,

we are producer of wear protection ceramics. On our webside etec-ceramics.com you will find many pictures for different applications.

For support, please contact us directely.

Best Regards

Sebastian Hofmann ■

Re: Lining Of Iron Ore Chutes

Hello Raja,

I work at bulktransshipment terminal EMO in Rotterdam.

We transport ironore and coal over our conveyorsystem with 4.5 m/sec. We lined the impactplaces with 50 mm ceramics. These last at least for the transport of 16.000.000 (16 million) tons. Then the 35 mm thick plug, in the hole where the fixing bolt sits, is worn away and we plan the replacement of the ceramic.

We order our ceramics in parts of 500 x 500 mm and fixed on a 5mm thick mountingplate on which we weld 4 studbolds for fixing it in place.

When your beldspeed is lower than ours, the ceramiocs last longer.

We use Tip-Top ceramics, but if you can get it local with a Mohs hardness of 9, you'll get the same results.

Good luck

Harry ■

Ceramic Liner

Dear sir,

We are the professional abrasion resistant ceramic make in china.

We have many applications for chute. we use the curved ceramic lined with special adhesive. the hardness can be above HR80, life time can be 8 to 10 times compare to the normal steel chute.

For more information and solutions, you can view www.kingcera.com or contact me directly antiwear@jcnmc.com

Regards

Jack ■

Ceramic Liners For Iron Ore Chutes

Dera Raja,

Looks like you are lining chutes at transfer points on a feed system feeding a sponge iron plant. If the tonnes per hour rate is less than 300 TPH you can consider castable wear resisting type ceramic lining under guidence from supplier of material. The lining will be about 50 mm thick. ■

Alumina Ceramic Linings / Ceramic Grinding Media

We are supplier of wear protection alumina ceramics, ceramic grinding media, precision ceramic parts and inert ceramic balls (catalyst bed support media).

Please check our blog web for more info about our products:

https://aluminaceramics.wordpress.com

If you are looking for an alternative supplier, we will be your choice.

Hope to work with you in the near future.

Best Regards,

Zhang Hongbo

Sales Manager

Qingdao CBC Co.,Ltd.

Suite 1006 Building No. 2 Celebrity International,

No. 39 Shiling Road, Laoshan Dist.,

Qingdao, China 266062

T: +86 532 8596 8596

F: +86 532 8596 8595

www.cbcceramics.com ■

Ceramic With Magnet Backside - New Product

href="showthread.php?p=38557#post38557" rel="nofollow">

What is the thickness of tile to be used, and the life we can achieve

pl. suggest

raja

Hi

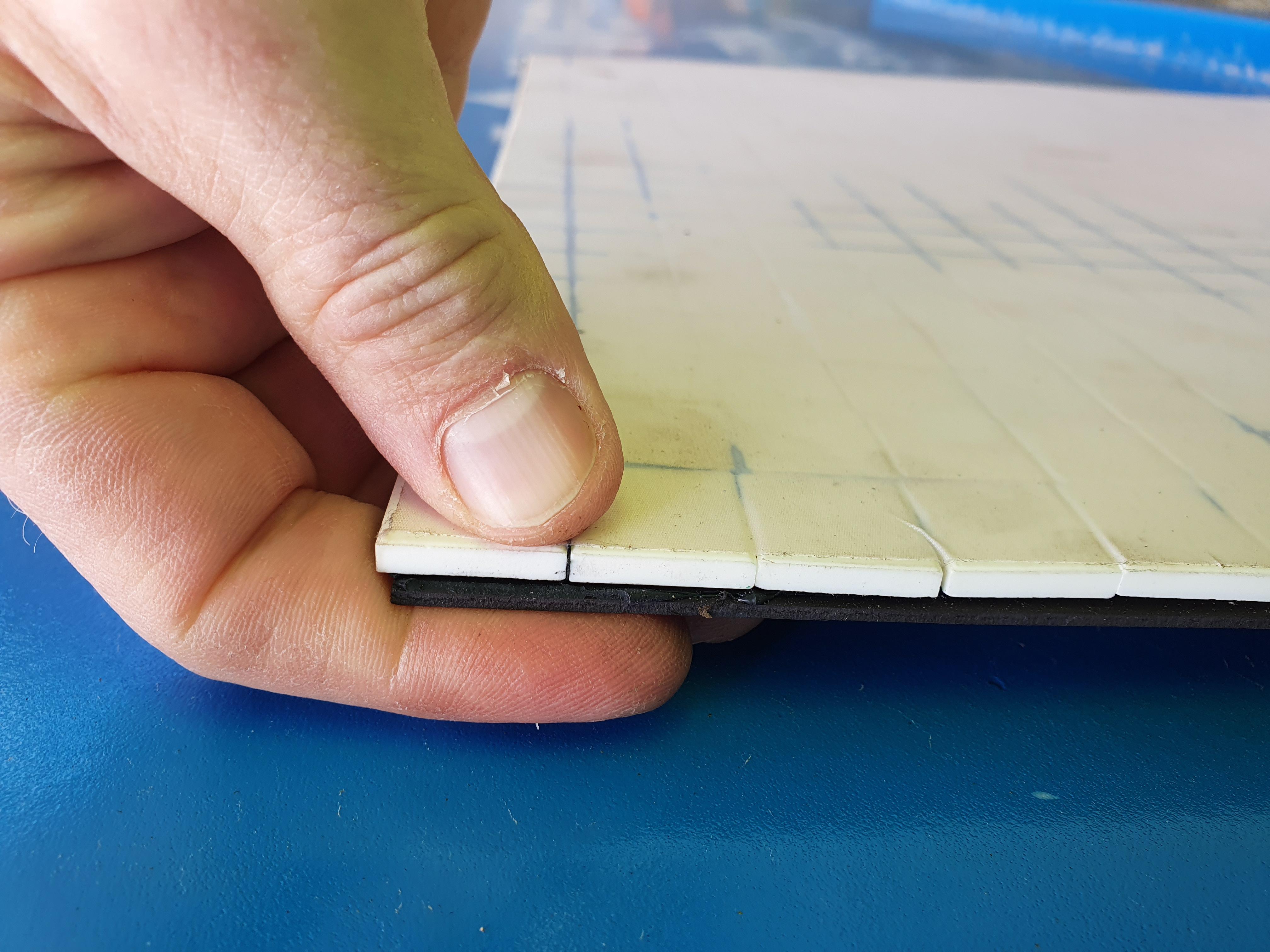

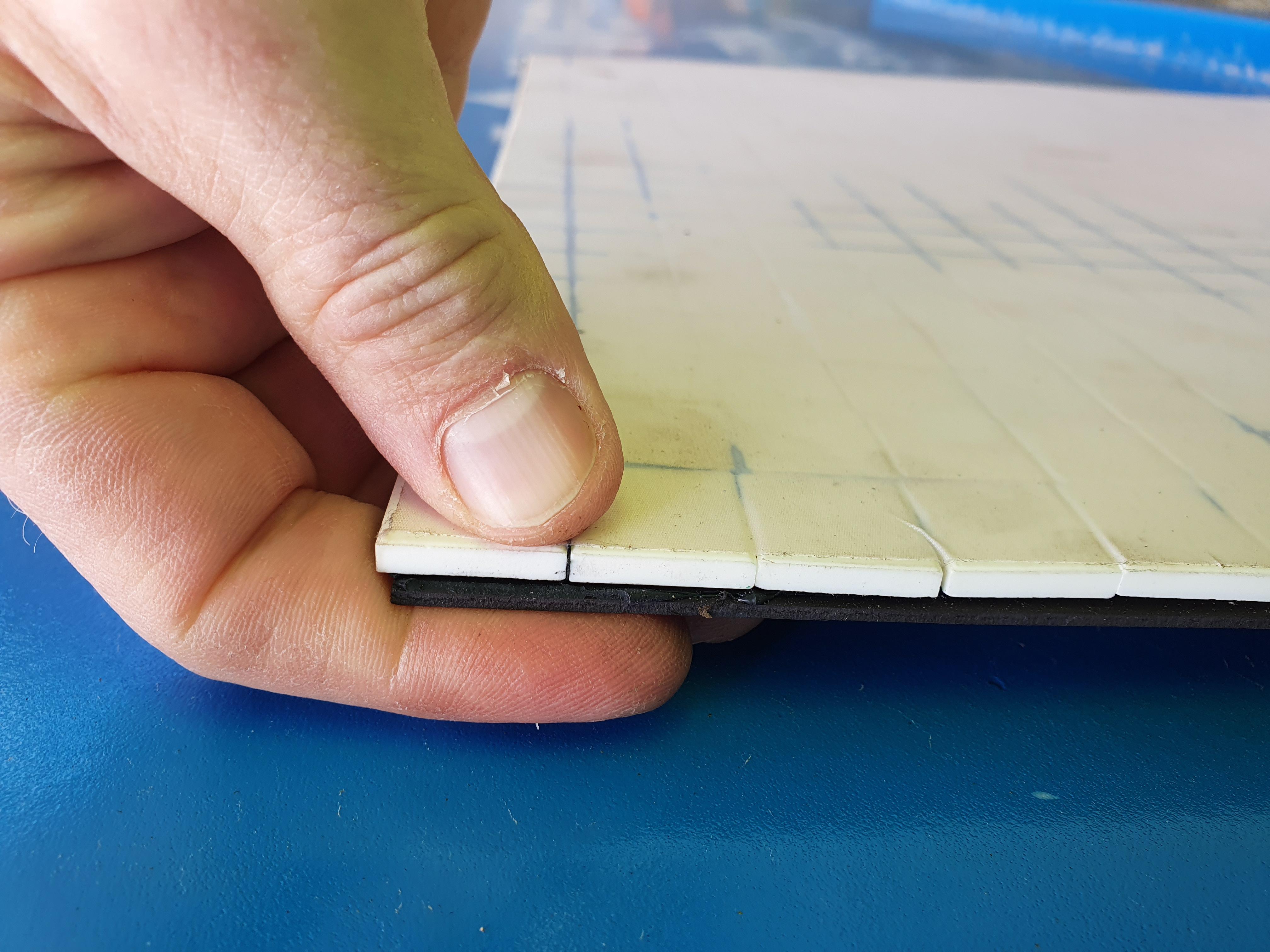

What about the new CeraMag? Ceramic 92% alu with magnet backside

href="https://forum.bulk-online.com/attachment.php?attachmentid=48158&d=1618390167" title="Name: Ceramag1.jpgViews: 34Size: 836.8 KB">Ceramag1.jpg ■

Ceramic With Magnet Backside - New Product

Alumina Ceramics, Zirconia Ceramics & Zta

Wear resistant ceramic lining – Alumina, zirconia & ZTA

Ceramic grinding media – alumina & zirconia

Steel & rubber backed ceramic plate

Pulley lagging

https://aluminaceramics.wordpress.com/ ■

Lining of Iron Ore Chutes

We want to line iron ore chutes with Alumina ceramics. The mix material contains iron ore lime powder and coke etc.

What is the thickness of tile to be used, and the life we can achieve

pl. suggest

raja ■