Ultimate Screening System (Continued)

Although possessing many customer-focused features, at the heart of the S-6 is the Doublescreen Box. This enables the screener to incorporate such mould breaking features as:

• Independent screen-box slope

• Independent screen-box vibration

• Independent screen-box amplitude

• Independent screen-box speed.

All resulting in fantastic output of accurate, quality products!

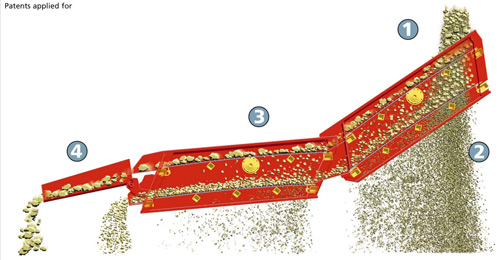

The Doublescreen box allows for over twenty different screening angles. Screening efficiency is maximised as material flow is directed by the angle of the screen box resulting in:

1. A steep angle for the primary screen-box ensures that the majority of the material is processed in the initial impact area.

2. The majority of the undersize is removed during initial impact.

3. Only near-size material passes to the secondary screen-box. This may be set flat enough to ensure any remaining material is screened efficiently.

4. Clean gradings, at very high out put, are produced as material is exposed to large screening area.

(Please see attached drawing).

With all the above features the S-6 promises to be the ultimate mobile screening system for the truly serious contractor or quarry operation. The S-6 represents the greatest innovation in mobile screening systems as it finally resolves the conflicting principles previously associated with providing an immense screening area on truly mobile plant.

Massive throughput, true mobility and a class leading screening area, results in the ultimate profit generator available today.

The S-6 is currently being demoed throughout the USA, and will receive its formal launch at the Bauma in Munich.

For more information, please visit:

href="https://edir.bulk-online.com/oldedirredirect/203150.htm" target="blank">https://edir.bulk-online.com/oldedirredirect/203150.htm

Attachments

■

Ultimate Screening System

7 March 2007

The ultimate screening system

Extec has launched the ultimate large production screen; the totally brand new – S – 6

The S-6 is based around the revolutionary Doublescreen concept that has taken the screening world by storm. Designed for the aggregate producer who requires large throughput, true mobility and clean gradings, the new S-6 encompasses such features as:

• Screening area consists of two individual 10x5 screen boxes, each possessing their own separate drive, and each being independently angled.

• The screen box arrangement presents a massive screening area, yet allows for an incredibly clean product through the independent set up of the two screen boxes.

• Longer, chevron belted side conveyors, in order to feed directly into a cone crusher, and/or possess vast stockpiling capacities.

• Longest tail conveyor in its class for even greater stock piling capacity.

• Faster running belts in order to facilitate high rates of production.

• Patented screen box lift mechanism to ease mesh change.

• New stronger chassis design for the most demanding of environments.

• Longer tracks in order to produce a stable screening platform.

These mould breaking attributes are combined with existing features found on the S-5 & S-4 doublescreens:

• Large hopper, with variable speed belt feeder, heavy-duty roller bed and heavy-duty belting.

• Heavy duty tipping grid activated by remote control.

• Unique Extec design Spreader plate to spread material across the full width of the screening facility whilst maintaining the velocity of the material particles.

• Optional world famous Extec Vibrating grid for breaking down of material prior to screening.

For more information, please visit:

https://edir.bulk-online.com/oldedirredirect/203150.htm

(Continued on next page)

Attachments

extec_news (JPG)

■