Brabender Food Grade Feeders (Continued)

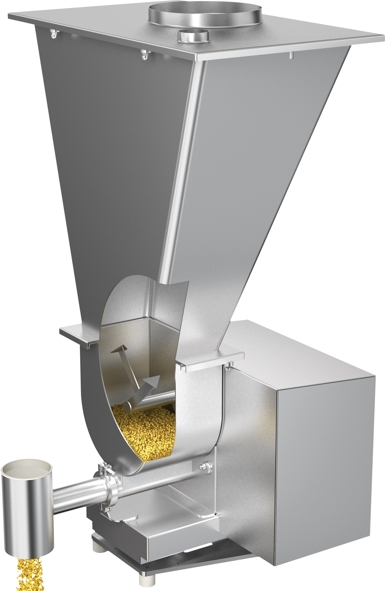

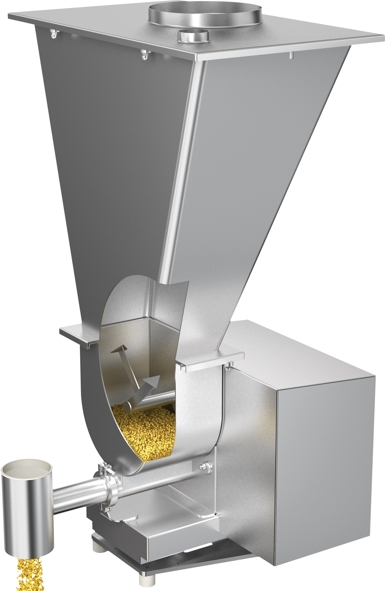

Brabender FlexWall®Food Feeder in "Hygienic Design"

The Brabender FlexWall®Food Feeder is a loss-in-weight feeder from the "Brabender Food Line". The feeder is the hygienic design variant of the well-known Brabender FlexWall®Plus Feeder from the standard product line renowned for its paddle agitated flexible polyurethane hopper. In addition to the hygienic design features that all feeders from the "Brabender Food Line" have in common, a broad variety of options allows to suit the feeder to the respective process requirements. Among others, the options include special FDA approved polyurethane hoppers, motor covers mad eof stainless steel, special motor finishes with food-proof and acid-resistant varnishes, stainless steel designs of base plates, junction boxes, subassembly chassis and load cells, downspouts and flexible connection sleeves made of FDA approved polyurethane, hoppers with directional grinding and many more.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1246-brabender-technologie.htm" target="blank">https://edir.bulk-online.com/profile...echnologie.htm

href="http://www.google.com/search?hl=de&client=safari&rls=de-de&q=Brabender+site%3Abulk-online.com&btnG=Suche&lr=" target="blank">http://www.google.com/search?hl=de&c...btnG=Suche&lr=

Attachments

■

Brabender Food Grade Feeders (Continued)

Brabender Screw Feeders in "Hygienic Design"

The Brabender loss-in-weight scale with stirring screw feeder from the "Brabender Food Line" is the hygienic design variant of the according loss-in-weight feeder from the standard product line. Further to the hygienic design features that all feeders from the "Brabender Food Line" have in common, this gravimetric feeder additionally qualifies for the food industry by quick release fastening s for the extension hopper, the extension hopper cover and the screw tube allowing quick and easy dismounting and cleaning, by full load cells, screw drive and agitator drive enclosure, stainless steel juntion boxes and by flexible connection sleeves made of FDA approved polyurethane. All parts in touch with the ingredient metered are made of stainless steel.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1246-brabender-technologie.htm" target="blank">https://edir.bulk-online.com/profile...echnologie.htm

href="http://www.google.com/search?hl=de&client=safari&rls=de-de&q=Brabender+site%3Abulk-online.com&btnG=Suche&lr=" target="blank">http://www.google.com/search?hl=de&c...btnG=Suche&lr=

Attachments

■

Brabender Food Grade Feeders (Continued)

Brabender Vibrating Tray Feeders in "Hygienic Design"

The Brabender loss-in-weight feeder with vibrating tray from the "Brabender Food Line" is the hygienic design variant of the according loss-in-weight feeder from the standard product line. Further to the hygienic design features that all feeders from the "Brabender Food Line" have in common, this gravimetric feeder additionally qualifies for the food industry by some particularly sophisticated quick cleaning features. The hopper, the vibrating tray, the downspout and the flexible connection slleves - and thus all parts in touch with the ingredient metered - can be dismounted from the vibration drive without any tools. All fastening elements are captive and remain connected to the basic unit. The load cell allows free cleaning access. As the feeder has no rotating parts, it is particularly suitable for easily damageable and also for lumpy ingredients.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1246-brabender-technologie.htm" target="blank">https://edir.bulk-online.com/profile...echnologie.htm

href="http://www.google.com/search?hl=de&client=safari&rls=de-de&q=Brabender+site%3Abulk-online.com&btnG=Suche&lr=" target="blank">http://www.google.com/search?hl=de&c...btnG=Suche&lr=

Attachments

■

Brabender Food Grade Feeders (Continued)

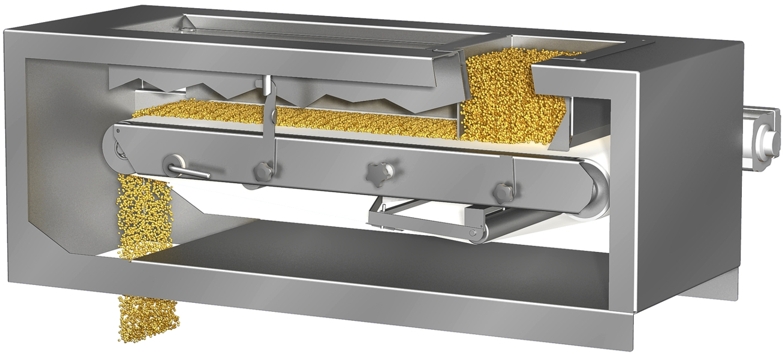

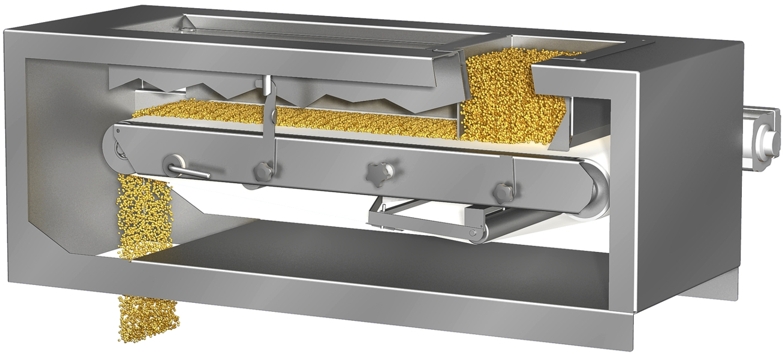

Brabender Weigh-Belt Feeders in "Hygienic Design"

The Brabender weigh-belt feeder from the "Brabender Food Line" is the hygienic design variant of the Brabender weigh-belt feeder from the standard product line. Further to the hygienic design features that all feeders from the "Brabender Food Line" have in common, this gravimetric feeder additionally qualifies for the food industry by a variety of special design features allowing quick and easy cleaning. The top lid and the side covers as well as the entire inlet shaft and the flexible connection sleeve can be removed without any tools. The feeder can be kept clean very easily due to well accessible, plain and smooth internal and external surfaces. The belt frame slides out to the side for easy cleaning but also for easy replacement of the food-proof belt. The chainless three-phase current motor is flanged on directly ("Direct Drive") and has no fan and cooling ribs. All junction boxes are made of stainless steel.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1246-brabender-technologie.htm" target="blank">https://edir.bulk-online.com/profile...echnologie.htm

href="http://www.google.com/search?hl=de&client=safari&rls=de-de&q=Brabender+site%3Abulk-online.com&btnG=Suche&lr=" target="blank">http://www.google.com/search?hl=de&c...btnG=Suche&lr=

Attachments

■

Brabender Food Grade Feeders (Continued)

Brabender DualTray Feeder in "Hygienic Design"

The Brabender DualTray Feeder from the "Brabender Food Line" is the hygienic design variant of the according loss-in-weight scale with vibratory mass flow feeder from the standard product line. As the feeder has no rotating parts, it is highly recommendable for easily damageable ingredients, ingredients with a high grain size variance, for lumpy media and for fibers. The feeder is particularly suitable for batching. Extraordinarily quick and easy dismantling and cleaning are its outstanding features. Having been decoupled from the vibration drive, the entire feed unit can be removed and further dismantled within minutes because the individual feed modules and the outlet cone are interconnected by quick clamping rings.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1246-brabender-technologie.htm" target="blank">https://edir.bulk-online.com/profile...echnologie.htm

href="http://www.google.com/search?hl=de&client=safari&rls=de-de&q=Brabender+site%3Abulk-online.com&btnG=Suche&lr=" target="blank">http://www.google.com/search?hl=de&c...btnG=Suche&lr=

Attachments

■

Brabender Food Grade Feeders

Gravimetric metering feeders for the food industry:

Brabender Food Line in "Hygienic Design"

Great demands on hygiene in the food industry do not only require easy cleanability of machines applied but also involve a wide range of additional measures to prevent contamination with microbiological, chemical and physiological contaminants. Equipment suppliers must make sure to comply with hygienic design principles.

For the field of bulk ingredient metering Brabender Technologie has therefore developed the "Brabender Food Line" in close cooperation with leading food companies, resulting in an array of metering feeders strictly complying with all relevant standards, guidelines and recommendations for the food industry (DIN EN 1672-2, EHEDG, FDA, etc.). On the one hand, special attention was given to technical solutions allowing particularly quick and easy cleaning. On the other hand, however, the development especially focused on preventive measures to avoid contaminations, for instance plain stainless steel surfaces, non-porous and ground welding seams without joints, elimination of cavities and hollow spaces, radial edges, FDA approved materials for ingredient-touched parts and gaskets, plus a vast variety of further details.

The resulting line of feeders comprises hygienic design versions of proven Brabender metering feeders, for instance loss-in-weight feeders like the Brabender FlexWall®Plus Feeder with its paddle-massaged flexible hopper, screw feeders with stirring agitators, vibrating tray feeders and "DualTray" mass flow feeders, plus the sturdy Brabender weigh-belt feeder for high feed rates despite compact dimensions. Thus the "Brabender Food Line" offers suitable metering feeders for virtually all bulk ingredients metered in the food industry, ranging from fine-grained to lumpy and damageable products.

Brabender Technologie is a member of the EHEDG (European Hygienic Engineering & Design Group).

For more information, please visit:

https://edir.bulk-online.com/profile...echnologie.htm

http://www.google.com/search?hl=de&c...btnG=Suche&lr=

Attachments

food-flexwall (JPG)

food-dsr (JPG)

food-dvt (JPG)

food-dualtray (JPG)

food-dbw (JPG)

■