Loesche Lag Mills For Wuhan

Two slag mills in Daqiuzhuang from Loesche Mills (Shanghai) Co. Ltd.

After several rounds of competition against other global bidders, the final decision that placing an order for two sets of LM 4600 CS 2 slag mill from Loesche China by Loesche Mills (Shanghai) Co. Ltd. has shown strong confidence in cooperation with Loesche Technology.

The Zhasan Youfa Iron & Steel Co. Ltd. is organized by Tianjin Metallurgy Group which is owned by government and another Youfa Company, with the Tianjin Metallurgy Group being main share holder. Up to now they are capable to supply the Iron and Steel up to 2.2 million tons per year.

With the workshop in Shanghai, Loesche8086 loesche.htm has been involved more business rang covering housing, frame, stand, static parts and etc. which has been proven to be a successful strategy to ensure equipment quality, delivery and technology know how of Loesche mill.

In order to ensure all the processes run smoothly, Loesche8086 loesche.htm was also responsible for project management, commissioning, erection supervision.

The contract has been signed and been effective April, 2012 and the components are due to be delivered by the end of 2012. Commissioning is scheduled for the beginning of 2013.

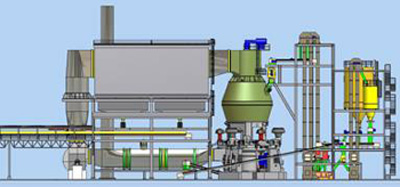

LOESCHE Mill Type LM 46.2+2, Wuhan Slag, China8086 loesche.htm

For more information, please visit Loesche8086 loesche.htm

Google search:

http://www.google.com/search?client=...ulk-online.comsearch?client=safari&rls=en&q=loesche+site:bulk online.com

http://www.google.com/search?q=loesc...=lnms&tbm=ischsearch?q=loesche+site:bulk online.com&hl=en&client=safari&rls=en&prmd=imvns&source=lnms&tbm=isch

Return to: www.bulk online.com ■

www.bulk online.com ■

Largest Cement Mill For Turkey

LOESCHE supplies Europe's largest Cement Mill to Turkey

NURYOL Cimento Sanayi ve Ticaret A.S. have decided to go all LOESCHE8086 loesche.htm.

For their new 4,000 tpd cement plant project in Karasu, about 150 km east of Istanbul, LOESCHE8086 loesche.htm will supply mills for coal grinding, cement raw material grinding and clinker grinding.

The complete project execution and coordination will be done by SINTEK Mining Machinery Industry Construction who are based in Ankara.

Within LOESCHE's scope of supply are one Loesche Mill Type LM 46.4 to grind cement raw material at a rate of 330 t/h at a fineness of 12 % R 90 u and a LOESCHE Mill Type LM 28.2 D to grind coal. The design capacity of the coal mill is 30 t/h at a fineness of 3 % R 90 u.

For cement grinding, NURYOL Cimento are convinced of the advanced and innovative LOESCHE cement grinding technology, including the patented roller pair design, and have therefore purchased a Loesche Mill Type LM 63.3+3, including process filter and fan. The mill is designed to grind OPC cement with a capacity of 240 tph at a fineness of 3,800 cm2/g according to Blaine.

This LOESCHE8086 loesche.htm Mill represents the largest Vertical Roller Mill for cement grinding in Turkey as well as in the whole of Europe. It will have a table diameter of 6.3 m and will be driven by a motor with a rated capacity of 7,200 kW.

The advanced LOESCHE8086 loesche.htm technology, ensuring the production of excellent product qualities with a high availability and very low energy consumption of the milling systems, were major decisive factors for NURYOL Cimento to trust LOESCHE for all three mills.

LOESCHE's innovative Compact Plant design for cement grinding plants was another important reason for NURYOL Cimento to choose a LOESCHE8086 loesche.htm Vertical Roller Mill for cement grinding.

The new LOESCHE8086 loesche.htm Compact Plant Design eliminates the necessity for a large and expensive mill building, leading to massive savings in required plant plot, in cost for structural steelworks and civil works as well as in erection time.

This is, amongst other LOESCHE innovations in this direction, possible due to LOESCHE's newly developed LDC classifier. This classifier is equipped with a patented gas flow straightener called "VORTEX Rectifier" which ensures an already homogeneous airstream at the classifier exit. Due to that a horizontal mill exit directly into the mill filter is possible. This leads for example into a reduced pressure drop of the mill system hence into savings in the specific power consumption of the complete grinding system.

In Turkey, LOESCHE8086 loesche.htm works together with their Partners from Taylan-Etker T.L.S. with head office in Istanbul.

LOESCHE's Compact Plant Design8086 loesche.htm

For more information, please visit Loesche8086 loesche.htm

Google search:

http://www.google.com/search?client=...ulk-online.comsearch?client=safari&rls=en&q=loesche+site:bulk online.com

http://www.google.com/search?q=loesc...=lnms&tbm=ischsearch?q=loesche+site:bulk online.com&hl=en&client=safari&rls=en&prmd=imvns&source=lnms&tbm=isch

Additional information on mills:

http://www.google.de/search?q=mills+...ulk-online.comsearch?q=mills+site:bulk online.com

http://www.google.de/search?q=mills+...=lnms&tbm=ischsearch?q=mills+site:bulk online.com&hl=de&safe=active&client=safari&rls=en&prmd=imvnsb&source=lnms&tbm=isch

Return to: www.bulk online.com ■

www.bulk online.com ■

News from Loesche

3600 tons clinker for Benin with a LOESCHE Mill LM 56.4

At the new Masse cement plant of Nouvelle Cimenterie du Benin, a production of 3600 t/a clinker is planned to be produced in Benin. The site is located in Benin, approx. 8 km north of the capital Porto Novo.

The client and CBMI are convinced of the Loesche8086 loesche.htm technology and have therefore decided in favor of the Loesche vertical roller mill. For the completely new line at Masse, a Loesche Mill Type LM 56.4 with a capacity of 320 t/h raw material grinding with a fineness of 12 % R 90 will be put into operation. The mill will be designed to grind a material with a maximum feed material moisture of 21 %. The mill motor is designed for a capacity of 3000 kW.

LOESCHE Mill LM 56.4 for Benin8086 loesche.htm

Delivery of the equipment is planned in 12 months according to contract, while commissioning is scheduled for the mid of 2013.

About Loesche8086 loesche.htm

Loesche8086 loesche.htm is an owner-managed, export-oriented company, which was founded in Berlin in 1906. Today, the company operates from its head office in Düsseldorf and has subsidiaries, representatives and agencies around the world.

It was in 1928 that Loesche8086 loesche.htm built the first spring-loaded air-flow mills, which even today are still known as Loesche mills. Nowadays, Loesche vertical mills form the core of many plants used to dry-grind coal, cement raw materials, granulated slag, industrial minerals and ores.

Thanks to its grinding plants with throughputs of 2 to 300 t/h for the cement industry and self-inert, central coal-grinding plants for hard and brown coal power stations, Loesche8086 loesche.htm is the global market leader for vertical mills and turnkey grinding mills.

Loesche supplies turnkey plants, which are individually planned and built for the required process steps. This includes plants for processing, material storage, transportation and delivery, vertical mills, hot-gas generators, filter and separator systems, complete automation technology, plants for all aspects of construction above and below ground, steel construction and piping systems.

The company has EN ISO 9001 certification and the grinding plants themselves are compliant with national and international safety regulations.

At present, around 330 people are employed at the company's head office in Düsseldorf, with around 650 employed worldwide.

For more information, please visit Loesche8086 loesche.htm

Google search:

http://www.google.com/search?client=...ulk-online.comsearch?client=safari&rls=en&q=loesche+site:bulk online.com

http://www.google.com/search?q=loesc...=lnms&tbm=ischsearch?q=loesche+site:bulk online.com&hl=en&client=safari&rls=en&prmd=imvns&source=lnms&tbm=isch

Return to: