News From Eriez®

Eriez® Eddy Current Separators Allow PET Flake Recyclers to Obtain High Purity and High Yield

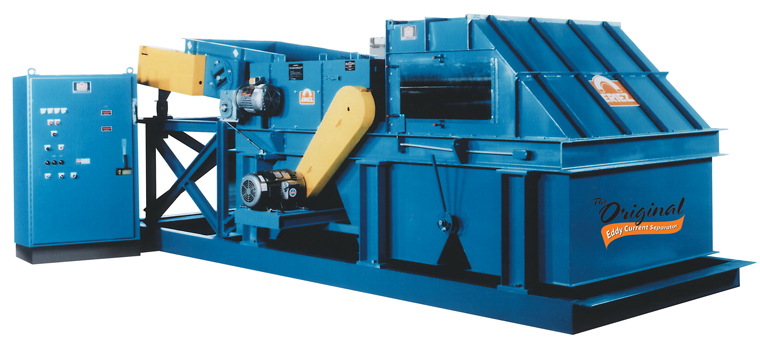

Erie, PA, USA - The recycling of beverage containers made from polyethylene terephthalate (PET) is garnering higher purity and yield with high speed, high strength eddy current separation technology from Eriez®.

Eriez’ newest line of Eddy Current Separators deliver exceptional nonferrous particle separation from PET flake. Recyclers can obtain a single pass aluminum reduction up to 92 percent and achieve a clean PET yield of 97 percent to 99 percent. According to studies conducted by Eriez, a one percent improvement in good product yield can save a company up to $230,000 in recycled PET annually with a 60-inch wide Eddy Current Separator.

Once the PET is purified, it can be re-used to make fiber, banding, or blended to make recycled content beverage and food containers. Recycled PET can be used in such diverse products as carpet, food containers, clothing, auto parts, tool handles and sleeping bag insulation.

Eriez’ Eddy Current Separators use powerful Rare Earth magnets that are arranged into a high-speed, composite shelled rotor. The PET containing metal contaminants—such as aluminum—is fed onto a conveyor belt in a controlled, low-density thin layer. The belt then passes over the rotating magnets and eddy currents are created in the aluminum.

When the polarity of the magnetic field around the aluminum is the same as the rotating magnets, the aluminum is repelled from the magnet. This causes the trajectory of the nonferrous metal to be different than the PET flake. The two streams of material are separated by an adjustable splitter in a simple, high-volume manner.

The heart of the separator is the Rare Earth Arched (REA) rotor, which uses powerful Rare Earth magnets that are curved to the shell contour. This high-frequency rotor has 22 poles and offers effective removal of small and medium nonferrous metals from aluminum cans as well as electronic scrap, plastics, glass cullet, foundry sand and urban wood waste. This REA rotor uses patented Kevlar/ceramic tile surface shells and grease retainer chambers and is balanced to operate up to 3200 RPM. Normal bearing life with good maintenance is calculated to be more than 15 years.

The equipment controls are housed in a NEMA 4-rated enclosure and include a belt speed tachometer. Also available is an Eriez vibratory pan feeder, hopper and belt conveyor to assure an even, controlled flake depth to enhance the separation performance.

Eriez is recognized as world authority in advanced technology for magnetic, vibratory and inspection applications. The company’s magnetic lift and separation, metal detection, x-ray, materials feeding, screening, conveying and controlling equipment have application in the process, metalworking, packaging, recycling, mining, aggregate and textile industries. Eriez manufactures and markets these products through ten international facilities located on six continents.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8251-eriez-magnetics-usa.htm" target="blank">https://edir.bulk-online.com/profile...netics-usa.htm

href="https://edir.bulk-online.com/profile/1803-eriez-magnetics-europe.htm" target="blank">https://edir.bulk-online.com/profile...ics-europe.htm

href="http://www.google.de/search?hl=de&client=safari&rls=de-de&q=Eriez+site%3Abulk-online.com&btnG=Suche&lr=&rediresc=&ei=0Xf-S4fdJoqXQbc8NjHCw" target="blank">http://www.google.de/search?hl=de&cl...JoqXQbc8NjHCw

Attachments

■

News From Eriez®

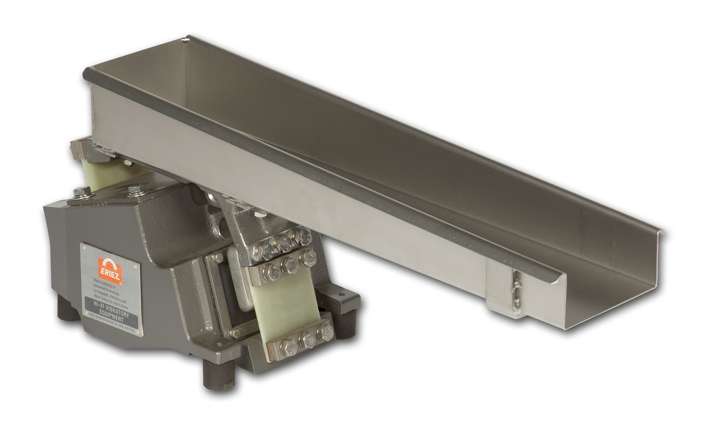

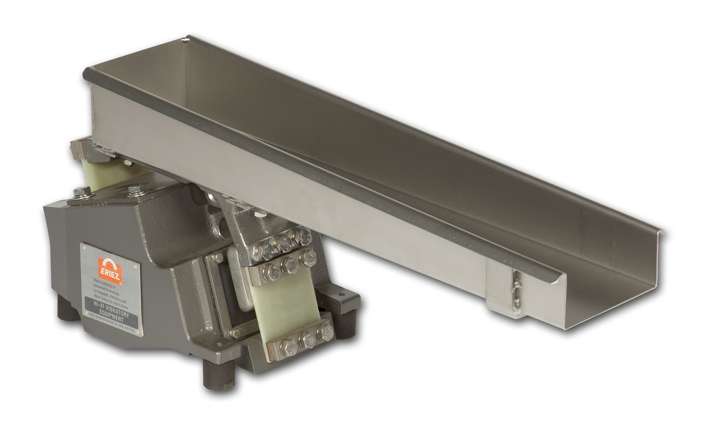

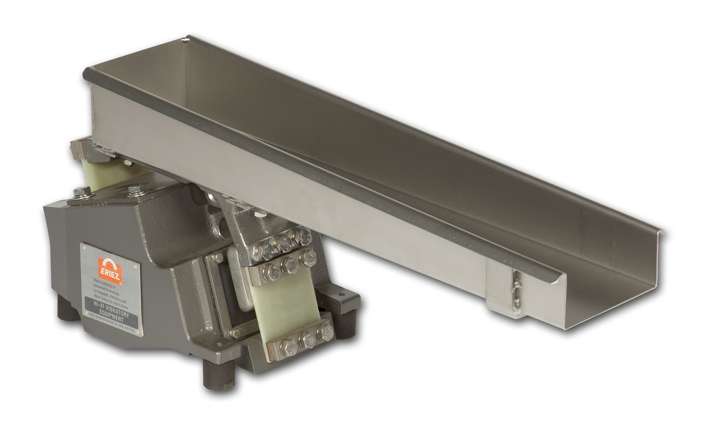

Eriez® Feeders Fast Program Ships Vibratory Feeders to Customers within Five Days of Placing Orders

Erie, PA, USA - Customers can choose from 33 different models of vibratory feeders and have them shipped within five working days after order placement using the Feeders Fast Program from Eriez ®, world authority in magnetic, vibratory and inspection applications.

Feeders Fast is an extension of the popular EriezXpress 5-Day, a service created to help the company serve customers more quickly by offering those with approved credit fast shipment of a wide assortment of Eriez feeder models. With available tray sizes beginning at 4” x 20” and ranging all the way up to 16” x 48” and capacities as high as 22 tons per hour, the 33 feeder models included in this fast-ship program fulfill many applications, large and small.

Units available through the Feeders Fast Program include two Model A feeders, which give precise feeding of the most minute amounts of materials. Tray sizes come in 4” x 20” and 7” x 14”. There are 11 units to choose from in Eriez’ Model C feeders, used for capacities larger than the Model A units can handle. Tray widths range from 5” to 14” and tray lengths from 20” to 48”.*

There are also 11 Eriez Model HS Feeders to choose from, which are designed for exceptionally high speed feeding of light, bulky materials, as well as many packaging applications. Tray widths range from 5” to 14” and tray lengths from 20” to 48”. Additionally, there are nine units from Eriez’ line of patented HD Feeders, which effectively handle powders and leafy products that cannot be fed successfully on an electromagnetic feeder.

Eriez is recognized as world authority in advanced technology for magnetic, vibratory and inspection applications. The company’s magnetic lift and separation, metal detection, x-ray, materials feeding, screening, conveying and controlling equipment have application in the process, metalworking, packaging, recycling, mining, aggregate and textile industries. Eriez manufactures and markets these products through ten international facilities located on six continents.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8251-eriez-magnetics-usa.htm" target="blank">https://edir.bulk-online.com/profile...netics-usa.htm

href="https://edir.bulk-online.com/profile/1803-eriez-magnetics-europe.htm" target="blank">https://edir.bulk-online.com/profile...ics-europe.htm

href="http://www.google.de/search?hl=de&client=safari&rls=de-de&q=Eriez+site%3Abulk-online.com&btnG=Suche&lr=&rediresc=&ei=0Xf-S4fdJoqXQbc8NjHCw" target="blank">http://www.google.de/search?hl=de&cl...JoqXQbc8NjHCw

Attachments

3_eriez_model_26c_feeders_f (JPG)

■

News from Eriez®

Eriez® E-Z Tec® X-Ray Inspection Systems Ensure Quality in Pharmaceutical Applications

Erie, PA, USA - Eriez’ E-Z Tec® X-Ray Inspection Systems deliver the highest level of product and packaging integrity for pharmaceutical applications. “When it comes to foreign object detection, most companies leave themselves vulnerable as they restrict inspection of foreign objects to the tablet press rooms using metal detectors,” says Ray Spurgeon, Eriez Product Manager—Inspection Systems. He continues, “Pharmaceutical processors now have a better choice with Eriez’ sophisticated X-Ray Inspection Systems.”

Eriez X-Ray Inspection Systems employ advanced linear array technology for superior sensitivity, speed and sophistication for both loose product flow and packaged inspection. Eriez X-Ray Inspection Systems monitor product and package attributes such as count, mass, fill level, broken or damaged product, as well as detecting unwanted metals, stone, glass, bone and some plastics.

Spurgeon explains that X-Ray technology offers advantages for pharmaceutical operations over metal detection alone. He says, “Metal detectors do not have the technology to be used on a packaging line when it comes to foil blister packs or safety seals on bottles. For these situations, X-Ray Inspection is a better choice.” He adds, “Eriez’ X-Ray Inspection Systems can also detect when a tablet or capsule is missing or crushed and can confirm the presence of a patient information leaflet. “

Product inspection is achieved through a computer controlled family of low energy generators and a high performance computer image analysis system. This makes Eriez E-Z Tec X-Ray Inspection Systems superior at detecting small statistical variations in the product that signal contamination or deviation from accepted specifications. Sophisticated image processing software provides immediate analysis, detection and rejection – automatically.

Now, Eriez offers Online X-Ray Testing where participants can "virtually" attend material tests in real time via a password-protected Web site. Potential customers can see their products passing through an Eriez E-Z Tec X-Ray Inspection System to determine its performance for foreign object detection, mass, fill level or missing items. Multiple viewers can watch from different locations and ask questions live to Eriez' test personnel.

Eriez is recognized as world authority in advanced technology for magnetic, vibratory and inspection applications. The company’s magnetic lift and separation, metal detection, x-ray, materials feeding, screening, conveying and controlling equipment have application in the process, metalworking, packaging, recycling, mining, aggregate and textile industries. Eriez manufactures and markets these products through ten international facilities located on six continents.

For more information, please visit:

https://edir.bulk-online.com/profile...netics-usa.htm8251 eriez magnetics usa.htm

https://edir.bulk-online.com/profile...ics-europe.htm1803 eriez magnetics europe.htm

http://www.google.de/search?hl=de&cl...JoqXQbc8NjHCwsearch?hl=de&client=safari&rls=de de&q=Eriez+site%3Abulk online.com&btnG=Suche&lr=&rediresc=&ei=0Xf S4fdJoqXQbc8NjHCw

Attachments

1_e-ztecxr-21 (JPG)

eriez_logo (GIF)

■