Waving...

Hello,

to my knowledge there's still no microwave or acoustic blocked chute sensors as such (purchaseable solution). An application to your environment would need to be developed, however

- microwave vs. iron ore seems a challenge (laws of physics, induction / microwave to iron particle behaviour)

- acoustic seems difficult as the sound pattern within a / each chute would be different and altering with different ores / surroundings etc.

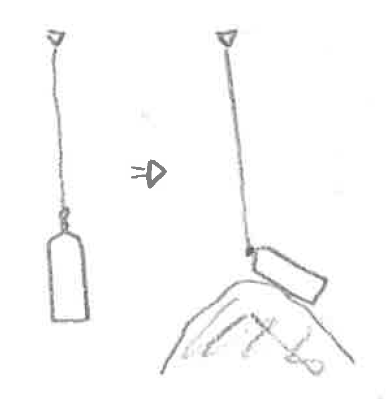

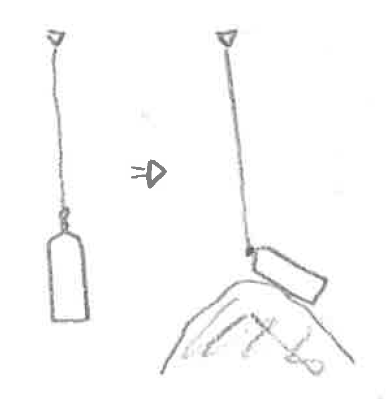

I do not fully perceive the specificalities of the solution you apply (sketch... ;-) would be most welcome), but then a / the common solution imo is an inclination sensor within a pending carrier case which gives off the signal once the material filling up the chute reaches the sensor and makes it tilt.

Regards ■

Re: Blocked Chute Microwave Switch

to my knowledge there's still no microwave or acoustic blocked chute sensors as such (purchaseable solution). An application to your environment would need to be developed, however

- microwave vs. iron ore seems a challenge (laws of physics, induction / microwave to iron particle behaviour)

- acoustic seems difficult as the sound pattern within a / each chute would be different and altering with different ores / surroundings etc.

I do not fully perceive the specificalities of the solution you apply (sketch... ;-) would be most welcome), but then a / the common solution imo is an inclination sensor within a pending carrier case which gives off the signal once the material filling up the chute reaches the sensor and makes it tilt.

Regards

Hi Roland,

Thank you very much for your thoughts.

On our site we currently use flap switches, signalling from a proximity unit when the angle of the flap changes beyond certain levels. The main problem with this method is that we are getting quite a few false blocked chute faults, and some of the typical causes are:

- Inconsistent feed rate through the chute,

- On a crash stop of the route (for instance due to a downstream fault), a chute fills up with ore; after the fault is rectified, the system is restated and the chutes are emptied. However occasionally ore/rocks are stuck in between the flap switch and the chute wall (proximity switch sensor activated) giving a false blocked chute indication.

We do have a few chutes on site where microwave switches are used for this purpose. However these switches are in the fines chutes of the screening house, the rate is pretty low at around 2.5 ktph and the chutes are of a different design compared to all other chutes on site. The good thing about these microwaves is that we never get false block chute indications.

My main concern would be how to position these sensors so they don't get damaged and that they are not in the ongoing production stream.

I would be very interested to hear your thoughts. ■

Patterns

Hello,

concluding: If you'd know the filling pattern of each critical chute you would be able to define a "point of no return" for a chute to recover from say an inconsistency in the inflow? Then, provided there's enough spare space in the chute, you could place the microwave sensor in a way that is protected from any damage and cover in the same time sufficient chute space to detect ~ above?

--> to the first issue: chute modelling by DEM, other modeling means or analysis by an experienced chute designer

--> to the second issue: this is clearly the know-how of the microwave sensor manufacturer to be relied upon

You see, w/o any picture or sketch or similar, one can only talk generalities... and as per now my own k/h on this topic is exhausted..however, there's quite a few specialists onboard this forum who could support !professionally! any deeper design issue of transfer chutes blockages etc., be it by - DEM - or - chute design - , just to name some of the searchwords available..

Regards ■

A Cast Iron Solution.

.... This normally occurs after the crash stops of the routes, when a chute fills up with ore and some dirt/rocks are stuck in between the chute door switch and the wall of the chute. Upon restart of the route, after the chute is emptied the door remains open (proximity switch activated) giving a false blocked chute condition.

....

If rocks are trapped between the switch and the chute walls the obvious answer is to relocate the switch, as implied by Roland's sketch. Old timers like me used a Trolex Bomb which was sufficiently robust, accurate and reliable. Despite what you might expect from the modern world it has not escaped from the clumsiness, dirt and simplicity of mineral handling. ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Blocked Chute Microwave Switch

Hi all,

I work in a large iron ore export terminal. The system is rather complex and includes a number of car dumpers, ship loaders, reclaimers and stackers.

We also have a large number of transfer chutes on site and each one is equipped with a blocked chute door switch. These chute doors are operated on the proximity switch principal. However the problem is that occasionally they detect false block chute conditions. This normally occurs after the crash stops of the routes, when a chute fills up with ore and some dirt/rocks are stuck in between the chute door switch and the wall of the chute. Upon restart of the route, after the chute is emptied the door remains open (proximity switch activated) giving a false blocked chute condition.

I have been thinking that microwave or acoustic switches might be more suitable for this application. However, my main concerns are:

- Can they be positioned in such a way that they are not damage in this rough environment inside the chute,

- How to position the acoustic/microwave switches so they don't detect the normal ore stream (during production) as a blocked chute condition.

Your experience and advice would be very much appreciated.

Many thanks! ■