Re: Belt Conveyor Discharge Trajectories

Happy New Year to all.

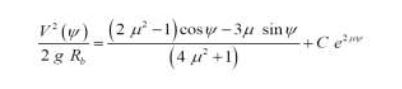

There is a better paper to read on trajectories and that is the thesis by Dr Shams Huque of the same University. The flow characteristics of whole grain and many dry, sized, particulate matter is quite predictable and therefore it is not that remarkable. This is why many engineers don't have a lot of problems designing transfers for sized washed coal. The difficulty comes in when we are handling adhesive materials whose flow characteristics alter with moisture content, water laden material and cohesive materials such as clay. There are also difficulties when handling materials where there is a broad spread of sizes in the ore such as ROM material and also when the material contains micro fines that can generate dust. Looking at trajectories and coming up with something that can be universally applied has been something I have spent a great deal of research on and a lot of reverse engineering. Like the university we have also done a great deal of scale modelling but our work in this area started a lot earlier (1995). Scale modelling has its own problems as you cannot size ore so you have to come up with materials that will simulate the ore flow. We summarise what we now do in our book "The Transfer Chute Design Manual" and believe we have a very good trajectory calculation method. Even then however we still rely on taking a conservative approach by introducing constants that will spread the trajectory profile as the key to design is ensuring you have the worse case scenarios covered or at least understood.

Cheers

Colin Benjamin

Gulf Conveyor Systems Pty Ltd

colin.benjamin@gcsm.com.au

www.conveyorsystemstechnology.com ■

Re: Belt Conveyor Discharge Trajectories

Re: Belt Conveyor Discharge Trajectories

I have my own copy as I sponsored Shams through his PhD but it is on the Wollongong University website under the heading "Ananlytical and Numerical Investigation into Belt Conveyor Transfers". It also covers a great deal of then current analysis on DEM that given time has been superseded by another PhD paper from the same University by Hastie (on the same website). You should find this interesting as well as it does reflect this very academic approach to trying to find empirical methods of evaluating transfers chutes but continually overlooks more practical and cheaper methods plus the cost and time constraints most designers are under. It was why Shams, Peter Donecker and I collaborated and wrote our design manual.

Cheers

Colin Benjamin

Gulf Conveyor Systems Pty Ltd

colin.benjamin@gcsm.com.au

www.conveyorsystemstechnology.com ■

Re: Belt Conveyor Discharge Trajectories

Re: Belt Conveyor Discharge Trajectories

I thought it was up. If you want to do further reading on trajectories email me and I will give you some further references.

Cheers

Colin Benjamin

Gulf Conveyor Systems Pty Ltd

colin.benjamin@gcsm.com.au

www.conveyorsystemstechnology.com ■

Re: Belt Conveyor Discharge Trajectories

I was just interested in reading it because of your comment

There is a better paper to read on trajectories

. Can you post it? ■

Re: Belt Conveyor Discharge Trajectories

There are no good general references that we have found except for the thesis of Shams that is why I suggested you email me as the list of specific references is very large. We have included in our Chapter 3 on trajectories the relevant parts of Sham's thesis so I could email a section of the book. It is far too large to post.

Cheers

Colin Benjamin

Gulf Conveyor Systems P/L ■

Re: Belt Conveyor Discharge Trajectories

hi all,

i've found on the web an excel file to calculate discharge ttrajectory, if you want it, pls e-mail me.

patrick

psegad@orange.fr ■

Re: Belt Conveyor Discharge Trajectories

Perhaps you could post the link here

.............................................. ■

Re: Belt Conveyor Discharge Trajectories

ok, excel file to calculate discharge trajectory

patrick

Attachments

belt conveyor - discharge trajectory(1) (ZIP)

■

Re: Belt Conveyor Discharge Trajectories

Thanks to you and Maria Cerda Cotes, for sharing. This might be helpful. ■

Re: Belt Conveyor Discharge Trajectories

I have taken the time to look at the trajectory model posted and it is very basic. If anyone cares to do some reverse engineering using actual transfers you will see where the differences are. There are many factors that have not been taken into consideration so anyone using this model must use it as a guide only.

Cheers

Colin Benjamin

Gulf Conveyor Systems Pty Ltd

www.conveyorsystemstechnology.com ■

Re: Belt Conveyor Discharge Trajectories

I invite you to look carefully at the graphs presented in the paper in the OP.

Who amongst you is running a belt at 5 to 7 m/s with a head pulley diameter of 250mm?

Think a little about transition geometry.

This is not scale modelling.

Trajectories scale with the Froude Number. Booth's flow criterion is no more than a statement of this fact, relating it to departure angle.

We have extensive experience of accurately predicting material trajectories using correct scaling rules, scaled transition geometries and appropriately selected test materials and surcharge angle. For dimensional similarity, head pulley diameter scales linearly, while belt speed scales according to the square of the belt velocity. The university does not appear to have grasped this point yet.

The Froude Number criterion enables you to determine when you have the slow belt case, where the situation becomes considerably more complex and highly dependent on material properties. ■

Belt Conveyor Discharge Trajectories

Over the Christmas break I've been reading "Conveyor Belt Trajectories - Comparing Predicted to Experimental Results" by Hastie and Wypych published in "bulk solids handling, Technology Special".

I'm interested to see that "the Booth method provides a very good prediction of the experimental trajectories for both polyethylene pellets and corn under a wide range of belt speeds".

Not bad for something developed some 75+ years ago. ■