News From Malvern Instruments

Malvern Link II the valuable new tool for system integration engineers

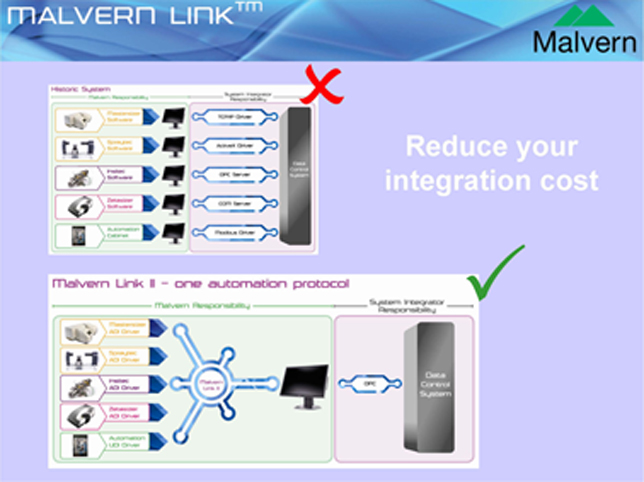

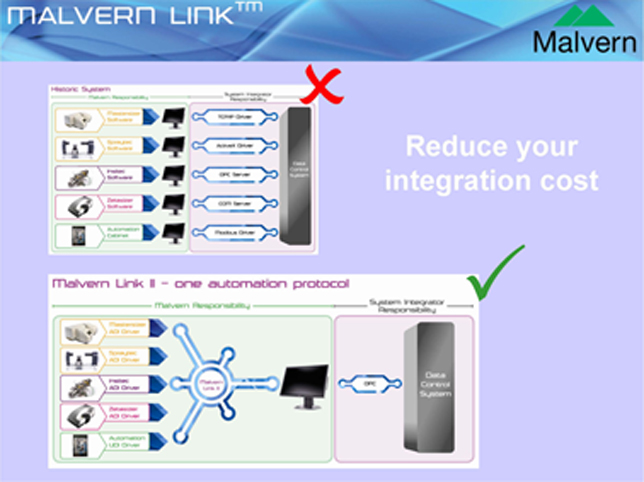

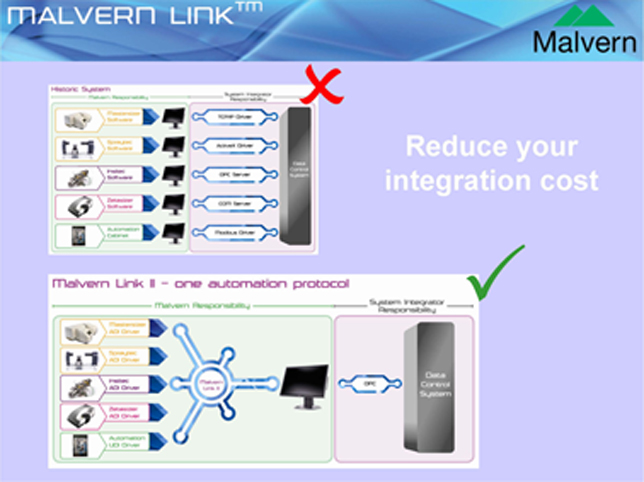

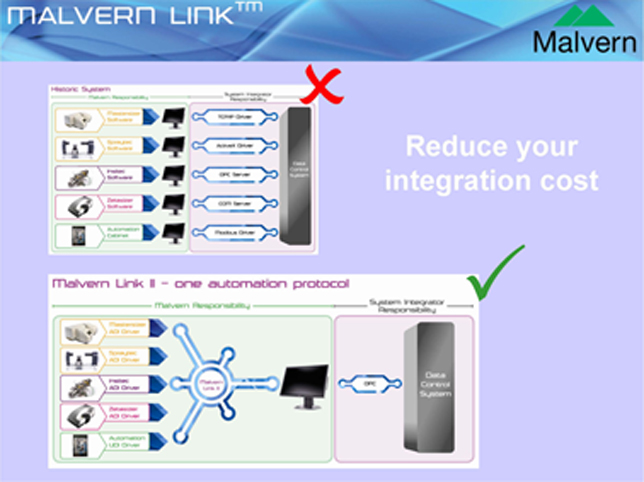

April 29 , 2010 - Malvern, UK: Malvern Instruments has launched Malvern Link II, a new and powerful OPC-standardized software package that simplifies the integration of analytical devices with expert control systems in manufacturing processes. A valuable tool for system integration engineers, Malvern Link II promotes the development of future-proof control solutions, reducing the cost of upgrades and future maintenance.

OPC (

href="http://www.opcfoundation.org" target="blank">www.opcfoundation.org) is recognised universally and promotes open connectivity via open standards. Using the latest OPC protocol, Malvern Link II transforms analyzer integration for automated control from being a costly, bespoke task for each individual plant to a more rapid, routine and cost-effective procedure. Not only does Malvern Link II deliver a single interface for remote control and reporting, its building-block concept allows multiple and unlimited configuration of automation devices and analyzers, including Malvern’s range of particle characterization systems. Importantly, it is fully compliant with pharmaceutical industry requirements.

The use of in- and on-line analyzers is increasingly widespread but they only fulfil their ultimate potential when used for automated control. Automatically driving the plant, using a multivariate model that gathers information from all relevant sources, is the benchmark for truly optimal operation.

While many instrument manufacturers have developed customized solutions to link their products with existing control systems, these often use non-standard proprietary software drivers that do not share a common platform. Unfortunately this approach discourages integration with other systems leading to the formation of unconnected ‘data islands’, real-time information streams that are not connected.

Using Malvern Link II, developing control architectures that can acquire and use data, not only from Malvern systems but also from a diverse array of different analyzers, eliminates the need for multiple dedicated solutions. With a simple drag and drop tool that allows the sequencing of many standard operating procedures, Malvern Link II can be used to create limitless process scenarios with fully customized presentation of data and live displays.

href="http://www.malvern.com/malvernlink" target="blank">http://www.malvern.com/malvernlink

Malvern, Malvern Instruments and Insitec are registered trademarks of Malvern Instruments Ltd

About Malvern Instruments

Malvern Instruments is a market leader in measuring performance controlling material properties. These include particle size, particle shape, zeta potential, molecular weight, size and conformation, rheological properties and chemical distribution. Malvern delivers the systems, support and expertise that ensure the analytical rigor and productivity needed to drive research, development and manufacturing.

Malvern’s measurement solutions for scientists, technologists and engineers advance continually through customer collaboration. Complementary materials characterization systems deliver inter-related measurements that reflect the complexities of particulates and disperse systems, nanomaterials and macromolecules. Combining intelligently implemented technologies with in-depth industry applications knowledge and support, Malvern provides customers with the competitive advantage they demand.

Headquartered in Malvern, UK, Malvern Instruments has subsidiary organizations in all major European markets, North America, China, Korea and Japan, a joint venture in India, a global distributor network and applications laboratories around the world.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1353-malvern-instruments.htm" target="blank">https://edir.bulk-online.com/profile...nstruments.htm

href="http://www.google.de/search?hl=de&client=safari&rls=de-de&q=Malvern+site%3Abulk-online.com&btnG=Suche&lr=&rediresc=&ei=32b-S-y7F4HgnAPf0IimDA" target="blank">http://www.google.de/search?hl=de&cl...F4HgnAPf0IimDA

Photo: Malvern Link II concept

Attachments

■

News From Malvern Instruments

Malvern Mastersizer 2000 helps manufacturers improve battery design

May 26 , 2010 - Malvern, UK: As battery developers and manufacturers strive to combine even greater power storage and output into lightweight, fast-charging products, the Mastersizer 2000 laser diffraction particle size analyzer from Malvern Instruments is proving valuable in characterizing the materials used to make electrodes.

The particle size distribution of battery electrode materials influences the rate of electrochemical reaction within the cell, having an effect on both the power density and storage capacity of the finished product. With its unique optical setup, the Mastersizer 2000 allows comprehensive characterization of the mixtures of nanometre and micron sized particles often used in electrode production. The resulting data inform electrode design, ultimately influencing the battery’s final performance.

Fast, accurate and having a dynamic range of 0.2 to 2000 microns, the Mastersizer 2000 comfortably covers those sizes of interest for battery production. Consistent sensitivity across this range ensures accurate measurement of each size fraction, especially important when analyzing polydisperse materials.

To download an application note describing experimental details of the Mastersizer 2000 used to measure various electrode materials visit Malvern's website.

Malvern, Malvern Instruments and Mastersizer are registered trademarks of Malvern Instruments Ltd

For more information, please visit:

href="https://edir.bulk-online.com/profile/1353-malvern-instruments.htm" target="blank">https://edir.bulk-online.com/profile...nstruments.htm

href="http://www.google.de/search?hl=de&client=safari&rls=de-de&q=Malvern+site%3Abulk-online.com&btnG=Suche&lr=&rediresc=&ei=32b-S-y7F4HgnAPf0IimDA" target="blank">http://www.google.de/search?hl=de&cl...F4HgnAPf0IimDA

Photo: The Mastersizer 2000 from Malvern Instruments

Attachments

■

News From Malvern Instruments

SDTech/Malvern Instruments collaboration enters a new phase

Companies combine expertise to demonstrate the benefits of real-time particle size measurement

May 20, 2010 - Malvern, UK: Following a number of convincing trials over the past year, SDTech, a company specialising in the micronisation and analysis of powders, has opted to routinely use a dedicated Insitec Voyager system for on-line particle size analysis. This marks a new phase in the company’s collaboration with Malvern Instruments, whose range of Insitec laser diffraction systems provides continuous process monitoring solutions across many different manufacturing industries.

Insitec Voyager is an easily connected, mobile particle size analyzer capable of tracking even rapidly changing processes. It has been used successfully by SDTech to optimise conditions for contract grinding applications and to develop customised micronisation solutions. Permanent access to an Insitec Voyager will accelerate this work and allow SDTech to offer training on the use and benefits of continuous particle size measurement.

Commenting on the company’s experience Dr Jalil Benabdillah, CEO from SDTech said, “Although we have used Malvern particle size analyzers off line for some time, on-line measurement has brought a new dimension to our work. It allows us to observe in real time how process variables influence particle size, making it much easier to move quickly to an optimal operating point. For our feasibility study this reduces the amount of test material needed. Now we often require less than one or two kilograms, whereas before it would more usually have been between 50 to 100 kilograms. This is a major benefit for our customers, especially at the early stages of development, when material is often scarce, or for high value materials.”

For SDTech, each new contract presents a new process optimisation challenge. Cutting the time taken to identify the operating conditions needed to assure efficient manufacture of in-specification powders improves productivity as well as reducing the amount of feed material required.

The introduction of new training in the use of on-line particle size measurement for process control and optimisation is a welcome innovation for customers of both SDTech and Malvern Instruments. Complementing Malvern’s existing consultancy service, which is an authoritative tailored package that combines dedicated expertise with an in situ Voyager trial, the SDTech training will offer those interested in on-line particle sizing an alternative introduction to the technology. The new training program demonstrates what has been achieved using real-time measurement and the wide applicability of the Insitec solution.

Insitec Voyager is a mobile laser diffraction particle size analyzer for dry streams that contain particles in the size range 0.1 to 1000 microns. It is easily attached to any process line with appropriate tappings and measures up to four complete particle size distributions per second, thereby providing an ideal data stream for automated process control.

Malvern, Malvern Instruments and Insitec are registered trademarks of Malvern Instruments Ltd

For more information, please visit:

href="https://edir.bulk-online.com/profile/1353-malvern-instruments.htm" target="blank">https://edir.bulk-online.com/profile...nstruments.htm

href="http://www.google.de/search?hl=de&client=safari&rls=de-de&q=Malvern+site%3Abulk-online.com&btnG=Suche&lr=&rediresc=&ei=32b-S-y7F4HgnAPf0IimDA" target="blank">http://www.google.de/search?hl=de&cl...F4HgnAPf0IimDA

Photo: Insitec Voyager from Malvern Instruments

Attachments

■

News From Malvern Instruments

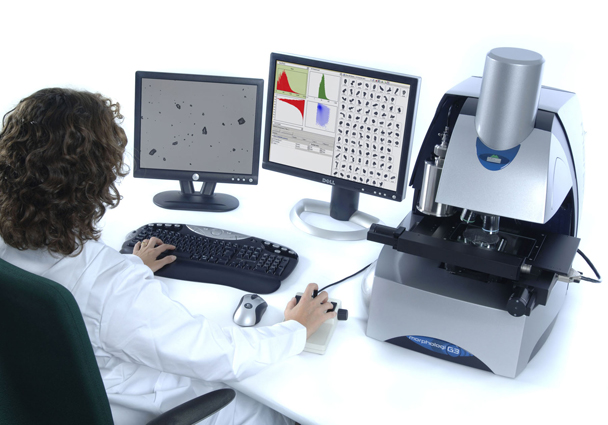

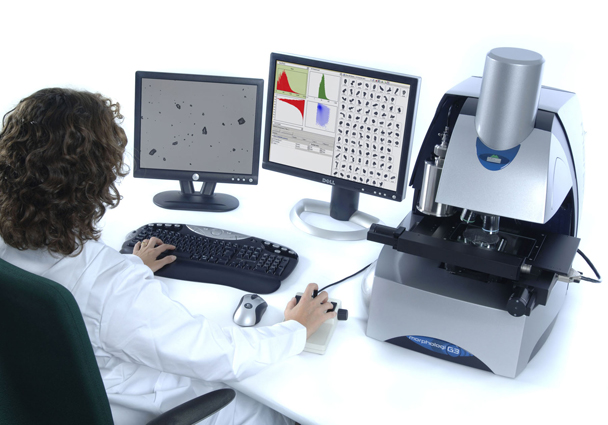

Characterizing the monodispersity of beads using Malvern’s Morphologi G3

May 27, 2010 - Malvern, UK: : A new application note describing a method for automating measurement of size and shape of micron scale beads is now available on the Malvern Instruments website. Careful control of bead size and shape is critically important in a wide range of applications including sensors, medical devices, chromatography and material fabrication. The presence of mis-shapen or fused beads may lead to problems with product performance. Using Malvern’s Morphologi G3 particle characterization system, automated measurements can be performed considerably more quickly than with manual microscopy and are not subject to the same operator variability. The application note, entitled; ‘Characterizing the Monodispersity of Beads Using the Morphologi G3’, is free to download at Malvern´s website.

Monodisperse spherical beads will pack in a way that results in a fairly well-defined network of pores which can be exploited in sensing applications. For example, a medical sensing device can depend on agglomeration of a protein to give a positive result. In this case, the agglomerated protein will not pass through the channels. A negative result is obtained when there is no agglomeration and no sample retention. The presence of fines in the packing material can block these pores and render the device unreliable by causing retention of smaller particles.

Malvern’s Morphologi G3 combines microscopy and image analysis to measure the size, shape and intensity of particles from 0.5 to 10000 m. It captures and stores images of every particle examined. Powerful software means that with just a few clicks of the mouse, data is transformed into useful information, allowing users to make decisions quickly and with confidence.

The Morphologi G3 particle characterization system is ideally suited to determining the quality and monodispersity of micron sized beads as well as identifying non-spherical particles. By analyzing shape as well as size, the Morphologi G3 adds a new dimension to the usefulness of particle characterization data. The system is automated, intuitive to use and requires little sample preparation

Malvern, Malvern Instruments and Morphologi are registered trademarks of Malvern Instruments Ltd

For more information, please visit:

href="https://edir.bulk-online.com/profile/1353-malvern-instruments.htm" target="blank">https://edir.bulk-online.com/profile...nstruments.htm

href="http://www.google.de/search?hl=de&client=safari&rls=de-de&q=Malvern+site%3Abulk-online.com&btnG=Suche&lr=&rediresc=&ei=32b-S-y7F4HgnAPf0IimDA" target="blank">http://www.google.de/search?hl=de&cl...F4HgnAPf0IimDA

Photo: The Morphologi G3 from Malvern Instruments

Attachments

■

News from Malvern Instruments

Malvern adds new applications to market-leading GPC/SEC system

April 27, 2010 - Malvern, UK: Malvern Instruments has extended the applications for its Viscotek Triple Detector Array (TDA), the multi-detector platform for gel permeation/size exclusion chromatography (GPC/SEC), through the inclusion of a new viscometer in the setup. The TDA maximises the productivity of GPC/SEC analysis by simultaneously measuring absolute molecular weight, molecular size and intrinsic viscosity. The new viscometer combines unrivalled sensitivity with an innovative 316 stainless steel transducer construction that offers excellent chemical resistance. It therefore provides the most precise intrinsic viscosity and structural information for an expanded range of biomolecules, natural and synthetic polymers.

The unique viscometer design uses digital inert transducer technology to give a faster, more sensitive response to viscosity changes than traditional transducers. Its 316 stainless steel construction means that there are now few limitations, in terms of salt content or pH, on the chromatographic conditions that can be used. This is a significant benefit for protein analysis. The use of inert capillaries in the measuring flow path is also advantageous for many biomolecule applications.

The TDA lies at the heart of the Viscotek TDAmax: a complete, advanced GPC/SEC system suitable for all macromolecular applications. However, each element of the TDA can be purchased alone or in combination, offering exceptional flexibility to those with existing GPC/SEC systems. UV and/or PDA detectors are also available to further augment detection capabilities. These are especially useful for the analysis of composition for copolymers and/or conjugated proteins.

For more information, please visit:

https://edir.bulk-online.com/profile...nstruments.htm1353 malvern instruments.htm

http://www.google.com/search?hl=de&c...btnG=Suche&lr=search?hl=de&client=safari&rls=de de&q=Malvern+site%3Abulk online.com&btnG=Suche&lr=

Photo: The Viscotek TDAmax from Malvern Instruments

Attachments

malvern_1_1 (JPG)

malvern_logo (JPG)

■