Brabender Loss-In-Weight Feeders (Continued)

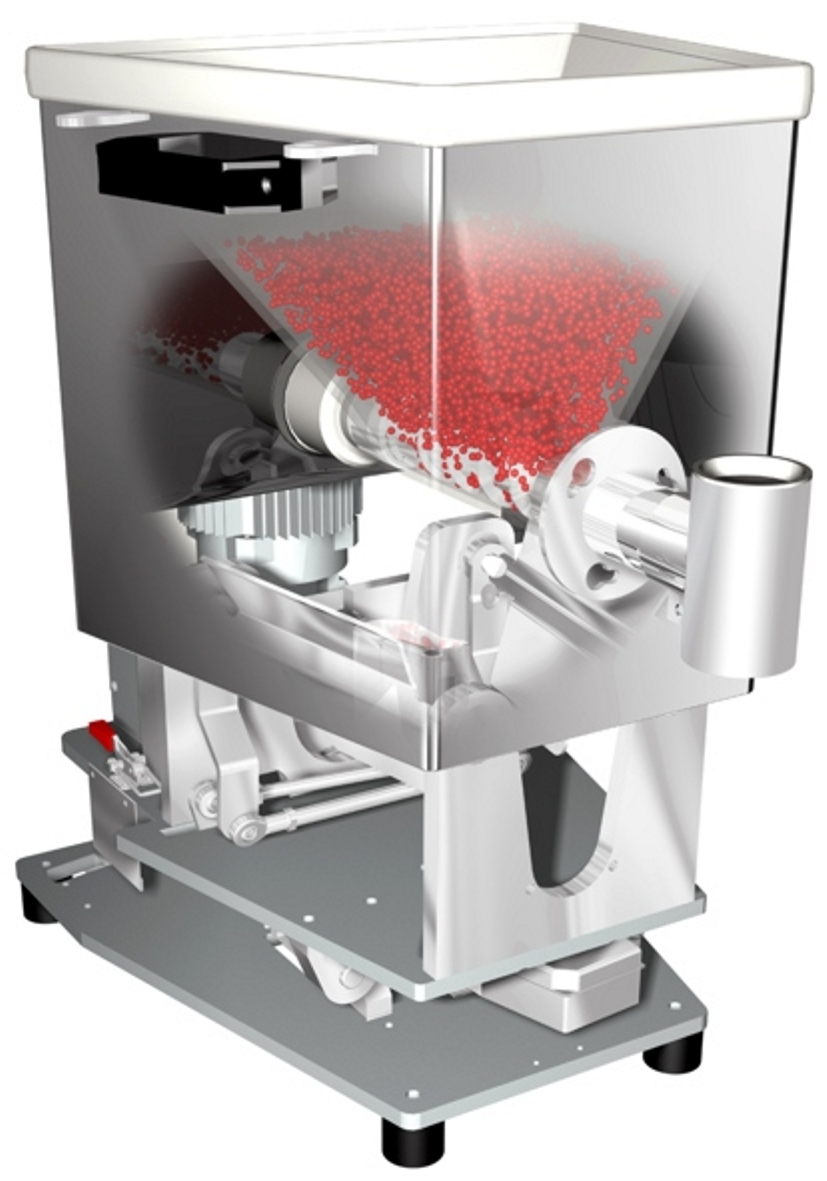

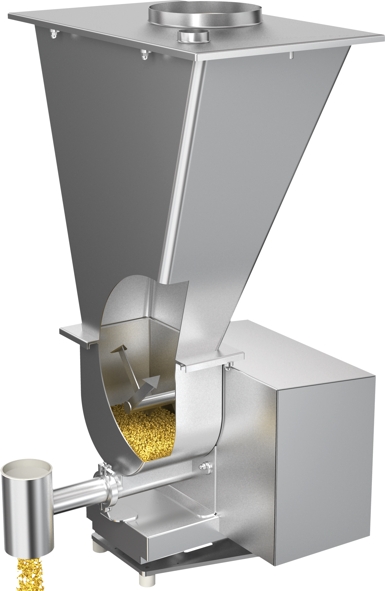

Brabender FlexWall®Plus Feeder

The Brabender FlexWall®Plus Feeder proven in world-wide applications is a super compact universal metering feeder for virtually all bulk ingredients conceivable.

The original Brabender FlexWall® feeding principle featuring a paddle-massaged flexible polyurethane hopper in conjunction with the trapeziform design and divergent hopper walls ensures real mass flow without bridging and makes the feeder independent of stirring agitators and their disadvantages. The trapezoid shape results in enormous floor space saving in circular arrangement of several units around a central point of discharge, allowing extraordinarily compact multiple feeder configurations. The digital load cell DigiMASS-2 with two vibrating wires compensates physical interference and ensures utmost reproducibility, linearity and long-term stability.

The Brabender FlexWall®Plus Feeder is equally suitable for powders, granules, pellets, flakes, chips, fluffs and glass fibres. Interchangeable single and twin screws allow optimum adaptation to changing ingredients and feed rates without feeder conversion and enable feeding of virtually 100 % of all flowable bulk ingredients – also of most critical additives. Exchanging the screw from the rear end within minutes is made easy by an optional pivoted drive motor.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1246-brabender-technologie.htm" target="blank">https://edir.bulk-online.com/profile...echnologie.htm

href="http://www.google.com/search?hl=de&client=safari&rls=de-de&q=Brabender+site%3Abulk-online.com&btnG=Suche&lr=" target="blank">http://www.google.com/search?hl=de&c...btnG=Suche&lr=

Attachments

fw plus schneckenwechsel (JPG)

■

Brabender Loss-In-Weight Feeders (Continued)

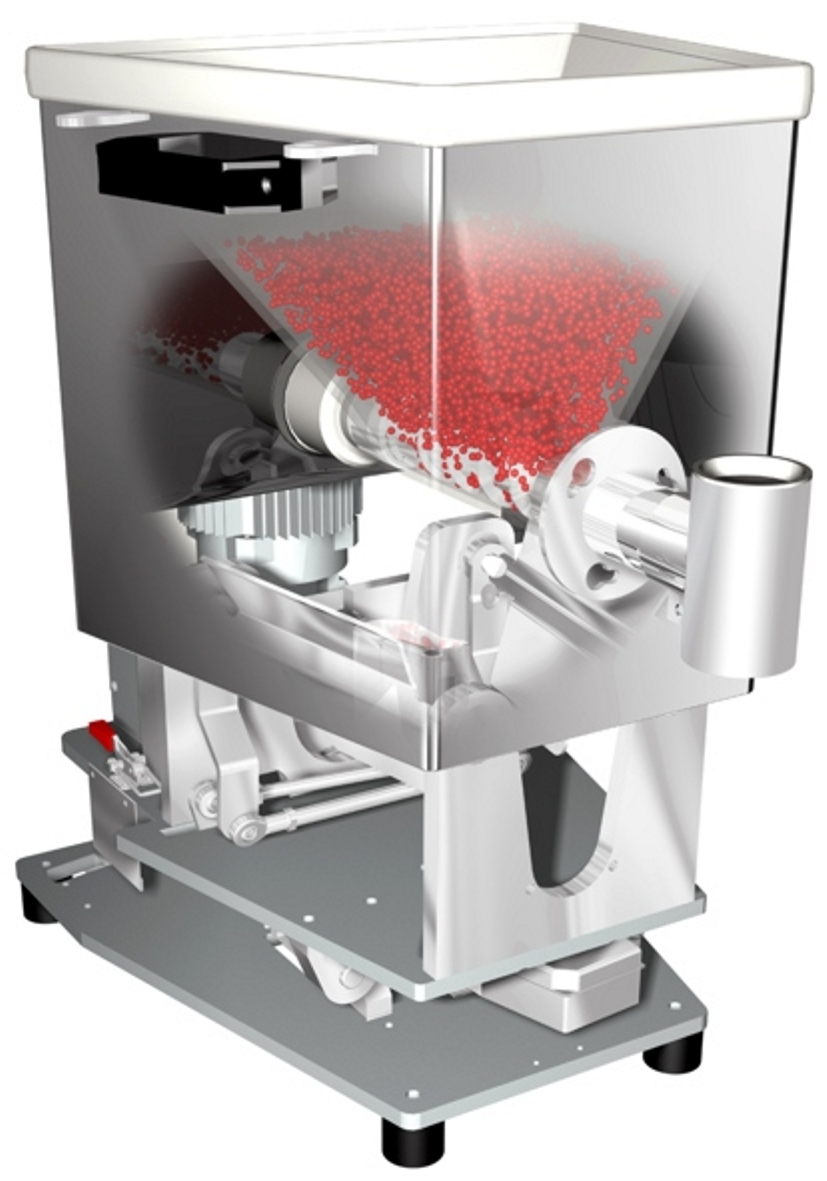

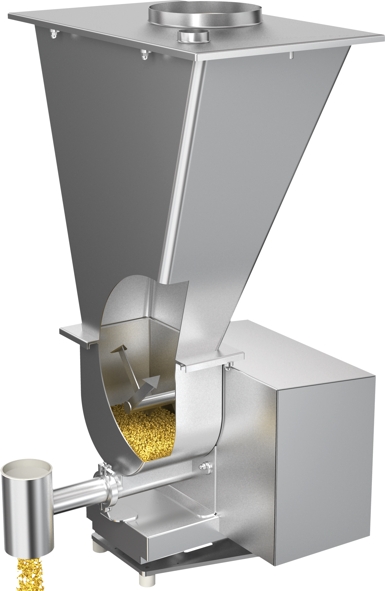

Brabender FlexWall®Plus "Easy Change" Feeder

The Brabender FlexWall®Plus "Easy Change" Feeder solves the problem of production runs with changing recipes composed of numerous different bulk ingredients and at varying feed rates. The hopper, screw, screw tube and casing are designed as one replaceable feed unit, which can be lifted off inclusive of the residual ingredient after having opened two quick-release locks while the drive motor, paddles and weighing unit remain in place. The design does not only allow convenient external cleaning of the ingredient-touched parts but also reduces downtime for recipe change-over to a minimum if the feeder is provided with a replacement unit containg the new ingredient. The new feed unit is simply put in place and fixed by the quick locks.

As the motor, the paddles and the weighing unit are required only once in the basic feeder, a larger number of ready-to-operate exchange feed units with different raw materials can be kept in stock at a low price. Of course they can be adapted to other ingredients and feed rates as well by a simple screw exchange. A multitude of interchangeable single and twin screws is available for that purpose.

The Brabender FlexWall®Plus "Easy Change" Feeder also yields substantial benefits where metering feeders need frequent cleaning because production can be continued with exchange units while cleaning the exchanged ones. As these have no electrical appliances, they are fully suitable for wet cleaning.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1246-brabender-technologie.htm" target="blank">https://edir.bulk-online.com/profile...echnologie.htm

href="http://www.google.com/search?hl=de&client=safari&rls=de-de&q=Brabender+site%3Abulk-online.com&btnG=Suche&lr=" target="blank">http://www.google.com/search?hl=de&c...btnG=Suche&lr=

Attachments

flexwall plus easy change (JPG)

■

Brabender Loss-In-Weight Feeders (Continued)

Brabender FlexWall®Food Feeder

The Brabender FlexWall®Food Feeder is a food-proof variant of the Brabender FlexWall®Plus Feeder and allows flexible feeder adaptation to different demands made by the food industry thanks to a variable package of options. Options available include special food-proof PUR hoppers, stainless steel motor enclosures, acid-resistant and food-proof motor paints, special stainless steel versions of base plates, junction boxes, mounting units and load cells, outlet downspouts and flexible connection sleeves made of food-proof PUR, casings and extension hoppers with directional grinding finish, radial corners and many more.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1246-brabender-technologie.htm" target="blank">https://edir.bulk-online.com/profile...echnologie.htm

href="http://www.google.com/search?hl=de&client=safari&rls=de-de&q=Brabender+site%3Abulk-online.com&btnG=Suche&lr=" target="blank">http://www.google.com/search?hl=de&c...btnG=Suche&lr=

Attachments

■

Brabender Loss-In-Weight Feeders (Continued)

Brabender FlexWall®Sanitary Feeder

The Brabender FlexWall®Sanitary Feeder is a variant of the Brabender FlexWall®Plus Feeder and has been systematically designed for sanitary applications, for instance in the cosmetics and pharmaceutical industries. So - on the one hand - utmost importance was attached to easy dismantling and cleaning. While the basic system already allows easy dismounting of the flexible hopper for wet or dry cleaning or - in case of one- way hoppers - for disposal, this was additionally put into practice for instance by the utilisation of quick connect couplings and quick connect screw joints for easy dismounting of component groups without tools. On the other hand, a particular goal was the effective prevention of contamination by microbiologically, chemically and physiologically harmful substances. This was achieved by using physiologically uncritical, FDA approved materials resistant to cleansing agents and disinfectants, high-quality stainless steels and a wide range of designing and manufacturing measures to prevent pores, recesses and hollows, which might otherwise promote bacteriological contamination due to deposits of dirt and liquids. For free flowing ingredients without the need of agitation the feeder is also available without paddles.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1246-brabender-technologie.htm" target="blank">https://edir.bulk-online.com/profile...echnologie.htm

href="http://www.google.com/search?hl=de&client=safari&rls=de-de&q=Brabender+site%3Abulk-online.com&btnG=Suche&lr=" target="blank">http://www.google.com/search?hl=de&c...btnG=Suche&lr=

Attachments

■

Brabender Loss-In-Weight Feeders (Continued)

Brabender FlexWall®Pharma Feeder

The Brabender FlexWall®Pharma Feeder combines the advantages of the FlexWall® principle featuring a paddle-massaged flexible hopper and compliance with the great demands made on hygiene by the pharmaceutical industry. The unit is designed for quick dismantling and cleaning. For disassemby, the feed unit consisting of flexible hopper, gear coupling, screw, screw tube and downspout can be removed as one unit for external dismantling and cleaning. For this purpose all its components are interconnected by quick clamping rings. Housing and extension hopper are also connected by a quick clamping ring. For reassembly, the feed unit is positioned in place and fixed to the gearing by means of the quick clamping ring. The sealing lip of the upper edge of the flexible hopper is then placed between housing and extension hopper. When connecting these by means of the quick clamping ring, the lip is pressed in for tight sealing. All sealings are equivalent to those of aseptic pipeline connections. The sealing system allows interior and exterior wet cleaning. The dynamic sealing at the gearing can be removed for cleaning by opening its quick clamping rings. A protective gas connection is available as an option. All steel parts in touch with the ingredient and the housing are made of stainless steel 1.4404 (≈ AISI 316 L). The flexible hopper consists of FDA approved PUR. The feeder is available as a single or as a twin screw model.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1246-brabender-technologie.htm" target="blank">https://edir.bulk-online.com/profile...echnologie.htm

href="http://www.google.com/search?hl=de&client=safari&rls=de-de&q=Brabender+site%3Abulk-online.com&btnG=Suche&lr=" target="blank">http://www.google.com/search?hl=de&c...btnG=Suche&lr=

Attachments

■

Brabender Loss-In-Weight Feeders (Continued)

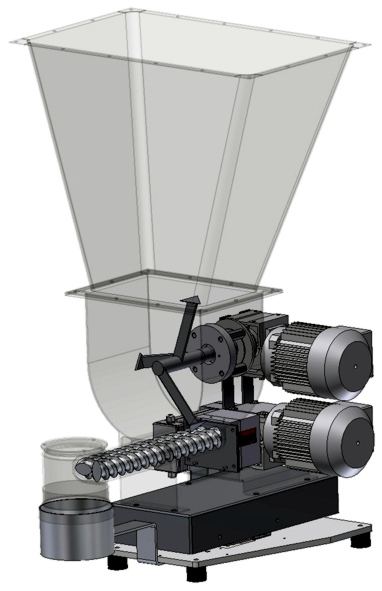

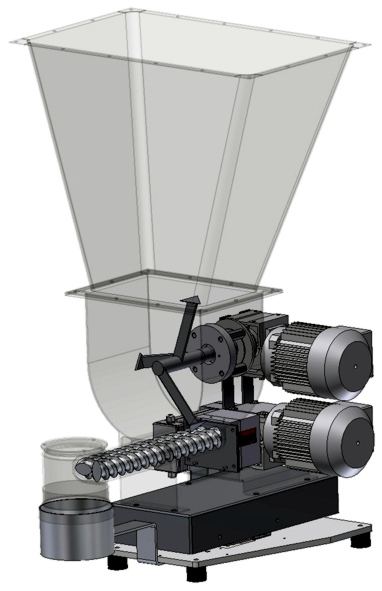

Brabender Loss-in-Weight Twin Screw Stirring Feeders

Brabender Loss-in-Weight Twin Screw Stirring Feeders feed bulk ingredients with problematic flow characteristics. Particularly the self-cleaning twin concave screws allow to feed powders with poorest flowability as well as adhesive, sticky or floodable bulk ingredients. A multifunctional stirring agitator in the screw trough ensures ingredient homogenisation, dependable flow and uniform screw filling. A variety of interchangeable screw profiles is available. Depending on the respective bulk material, double or twin spiral screws, twin blade screws or twin concave screws are used. The feeders are equipped with high-tech weighing systems DigiMASS-2 with two vibrating wires

For more information, please visit:

href="https://edir.bulk-online.com/profile/1246-brabender-technologie.htm" target="blank">https://edir.bulk-online.com/profile...echnologie.htm

href="http://www.google.com/search?hl=de&client=safari&rls=de-de&q=Brabender+site%3Abulk-online.com&btnG=Suche&lr=" target="blank">http://www.google.com/search?hl=de&c...btnG=Suche&lr=

Attachments

■

Brabender Loss-In-Weight Feeders (Continued)

Brabender Loss-in-Weight Feeders

with Vibrating Trays

Brabender loss-in-weight feeders with vibrating trays are gravimetric metering feeders especially for pellets and free flowing granular bulk ingredients. The feed modules are vibrating trays with variable speed electromagnetic vibration drives. The drives have vibration amplitude feedback systems ensuring linear characteristics of conveyance over the entire feed rate range. The feeders are equipped with high-tech weighing systems DigiMASS-2 with two vibrating wires or alternatively with high-resolution analog load cells.

For more information, please visit:

https://edir.bulk-online.com/profile...echnologie.htm

http://www.google.com/search?hl=de&c...btnG=Suche&lr=

Attachments

■

Brabender Loss-In-Weight Feeders (Continued)

Brabender MiniTwin Feeders

Brabender MiniTwin Feeders belong to the smallest twin screw feeders in the world and feed powders at minimum feed rates of a few grams per hour due to screw profiles of only 12 mm in diameter. Particularly for powder feeding at low rates, the self-cleaning twin concave screws offer excellent pulsation-free dispense. The feeders use the high-tech weighing system DigiMASS-2 with two vibrating wires.

For more information, please visit:

https://edir.bulk-online.com/profile...echnologie.htm

http://www.google.com/search?hl=de&c...btnG=Suche&lr=

Attachments

■

Brabender Loss-In-Weight Feeders (Continued)

Brabender RotoTube Micro Feeder

For feeding of fine-grained ingredients at rates of a few grams per hour Brabender offers the Brabender RotoTube Micro Feeder, a loss-in-weight feeder in miniature equipped with a rotary tube with an integrated particle guidance system. Particularly if granules are metered, individual grains can be dispensed virtually one after the other. An infinitely variable tilting system allows to tilt the tube for further feed rate adjustment. The loss-in-weight feeder uses the digital high-tech weighing system DigiMASS-2 featuring two vibrating wires.

For more information, please visit:

https://edir.bulk-online.com/profile...echnologie.htm

http://www.google.com/search?hl=de&c...btnG=Suche&lr=

Attachments

■

Brabender Loss-In-Weight Feeders (Continued)

Digital Load Cell DigiMASS-2

DigiMASS-2 stands for "Digital Mass Acqusition Sensor System – 2 Wires" and is a digital two-wire load cell for Brabender loss-in-weight feeders featuring real comparison of masses. Two wires arranged at a right angle to each other and prestressed by a comparison mass are excited by electrical exciters inducing resonance vibration. Applying a load to the wires changes their frequencies of vibration in proportion to the load, while one wire is loaded and the other is relieved. The frequencies are read in by a microprocessor, which converts the frequency ratio into a continuous serial weighing signal and transfers it to the controller of the loss-in-weight feeder. The frequency ratio as an absolute value is independent of physical ambient influences and remains constant even in case of changing ambient influences so that the measuring accuracy is not affected. In conjunction with an additional software filter for dynamic electronic vibration attenuation the system ensures utmost reproducibility, linearity and long-term stability and hence optimum feeding accuracy and reliability of gravimetric metering feeders. The microprocessor and the serial interface offer high-speed data communications and thus shortest reaction times in the feeder control loop. DigiMASS-2 has a theoretically utilizable internal resolution of 4,000,000 d and offers high electromagnetic compatibility.

For more information, please visit:

https://edir.bulk-online.com/profile...echnologie.htm

http://www.google.com/search?hl=de&c...btnG=Suche&lr=

Attachments

■

Brabender Loss-In-Weight Feeders (Continued)

"FeederScout" for Online Feeder Selection

The "FeederScout" is an online program provided by Brabender Technologie and finds the optimum loss-in-weight feeder or volumetric feeder for any feeding application. After the user has entered his basic data and has clicked the selection button, the "FeederScout" determines the optimum metering feeder best suited to the specific requirement in consideration of both technical appropriateness and cost-efficiency - along with a quotation, if requested. A giant database keeping a record of almost 15,000 feeding trials with thousands of bulk ingredients forms the basis of this unique program, which can give even the most experienced process engineers and plant designers more certainty about their choice of feeders. The "FeederScout" can be accessed from the website of Brabender Technologie. The according internet address can be found when clicking on the first information link below.

For more information, please visit:

https://edir.bulk-online.com/profile...echnologie.htm

http://www.google.com/search?hl=de&c...btnG=Suche&lr=

Attachments

■

Brabender Loss-In-Weight Feeders (Continued)

Brabender ScrewDisc® Loss-in-Weight Feeder

The Brabender ScrewDisc® Loss-in-Weight Feeder meters pellets and free flowing bulk ingredients. Compared with conventional screw feeders, its novel metering principle offers some remarkable advantages for these ingredients.

The principle is based on a vertical metering screw mounted on a rotating disc, arranged in a specially shaped outlet made of conductive transparent polyurethane allowing visual inspection. A tubular PUR insert slipped over the screw replaces the conventional screw tube. The entire unit as a whole is the actual feed unit. It is connected with a component part carrier via a lowering mechanism, which accommodates the load cell and also supports the storage hopper. The carrier is optionally included in the scope of supply or provided by the customer.

The ThreeFlex handling system allows rapid recipe changeover without tools in 3 work steps (1 - lowering, 2 - cleaning, 3 - ingredient changeover).

Beside the ThreeFlex system and its compact design due to the short inlet-outlet distance the feeder offers advantages because the vertical arrangement results in reliable solid flow and a constant screw filling level of virtually 100 %. The working principle allows a turndown ratio of 100:1 and pulsation-free discharge over the entire feed rate range due to optimum grain distribution around the circumference of the disc.

Brabender ScrewDisc® Loss-in-Weight Feeders are available as stand-alone feeders or as multiple ingredient feeding stations with up to 8 loss-in-weight feeders on a common base structure.

For more information, please visit:

https://edir.bulk-online.com/profile...echnologie.htm

http://www.google.com/search?hl=de&c...btnG=Suche&lr=

Attachments

■

Brabender Loss-In-Weight Feeders (Continued)

Loss-in-Weight Liquid Feeder

The Brabender Loss-in-Weight Liquid Feeder is available for liquids with low to high viscosities. It consists of a storage hopper weighed by a digital load cell and a variable speed feed unit. Both component groups are mounted on a common base structure but are isolated from each other by a highly flexible transition sleeve so as to avoid impairment to the weighing function. Depending on the properties of the medium metered (density, viscosity, solids content, temperature, reactivity, toxicological properties, etc.) and the respective process requirements (accuracy, feed rate, turndown ratio, counterpressure, etc.) the feed unit is chosen from a variety of metering pumps (piston, diaphragm, gear, hose, rotary piston or eccentric screw pumps, etc.). All Brabender Loss-in-Weight Liquid Feeders are available in heated design and explosion-proof in compliance with ATEX 95 (94/9/EG).

For more information, please visit:

https://edir.bulk-online.com/profile...echnologie.htm

http://www.google.com/search?hl=de&c...btnG=Suche&lr=

Attachments

■

Brabender Loss-In-Weight Feeders (Continued)

Loss-in-Weight Metering Off The Bulk Bag

For gravimetric bulk ingredient metering the Brabender Bulk Bag Unloader "BagMaster" is available in a loss-in-weight feeder version mounted on load cells and equipped with a built-in metering feeder. In conjunction with suitable feed controllers from the Brabender product line this configuration allows continuous or batch-wise metering directly off the bulk bag. The Brabender BagMaster is suitable for lined or unlined bulk bags up to 1.5 tons. Its most outstanding feature is an unconventional discharge system with massage ring mechanism ensuring mass flow inside the bag, uniform bulk ingredient discharge and complete emptying-out also of the bag corners even in case of poorly flowing ingredients. For metering the system uses the renowned Brabender FlexWall®Plus Feeders with paddle-massaged flexible hoppers.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1246-brabender-technologie.htm" target="blank">https://edir.bulk-online.com/profile...echnologie.htm

href="http://www.google.com/search?hl=de&client=safari&rls=de-de&q=Brabender+site%3Abulk-online.com&btnG=Suche&lr=" target="blank">http://www.google.com/search?hl=de&c...btnG=Suche&lr=

Attachments

■

Brabender Loss-In-Weight Feeders (Continued)

ScrewDisc®: ThreeFlex Handling System

Quick discharge, easy cleaning and ingredient changeover in record time without any tools were the defined goals when developing a handling concept for the ScrewDisc® loss-in-weight feeder. The result was the well thought out ThreeFlex Handling System allowing rapid conversion in just three work steps.

Step 1: Lowering

After unlocking two quick release clamps the feed unit slides down and separates from the storage hopper, which remains in place held by spring clamps. The polyurethane outlet can now be turned by 360° into any desired discharge position, while the integrated handles allow non-slip handling. For hopper emptying the locking bolt at the component part carrier is pulled so that the outlet slides down and clears the cross section of the PUR insert. As a result, the ingredient flows off.

Step 2: Cleaning

For cleaning the entire outlet unit is swung out to the side allowing unrestricted access to the feeder interior. The screw and the polyurethane insert can be removed. The storage hopper held by the spring clamps can also be taken off for cleaning. Wet cleaning of the hopper and also of the feed unit is possible thanks to the high enclosure protection (IP65) of the motor.

Step 3: Ingredient Changeover

In case feed rates also have to be changed when changing over from one ingredient to another, screws and PUR inserts are interchangeable for adaptation to varying requirements.

For more information, please visit:

https://edir.bulk-online.com/profile...echnologie.htm

http://www.google.com/search?hl=de&c...btnG=Suche&lr=

Attachments

■

Brabender Loss-In-Weight Feeders (Continued)

Brabender DualTray Feeder

The Brabender DualTray Feeder is a loss-in-weight feeder equipped with a mass flow feed mechanism utilizing natural bulk ingredient flow and gravity to produce vertical flow of the metered ingredient. Applying vibration changes the angle of repose of the resting ingredient and makes it flow. Similar to a cascade, the ingredient runs across vibrating feed plates arranged one above the other in opposite directions, while the feed rate is controlled by the vibration. As soon as the vibration is switched off again, the angle of repose is restored and ingredient flow is stopped instantaneously. Therefore the unit is particularly qualified for discontinuous batching feeding. The Brabender DualTray Feeder has no rotating parts and is thus perfectly suitable for damageable bulk solids, ingredients with differently sized grains, lumpy media and fibrous materials. Further features are ease of dismantling and cleaning. Having detached the feed unit from the vibration drive by simply releasing a fixation handle, the feed modules and the discharge cone - all interconnected by clamping rings - can be removed for cleaning or replacement.

For more information, please visit:

https://edir.bulk-online.com/profile...echnologie.htm

http://www.google.com/search?hl=de&c...btnG=Suche&lr=

Attachments

■

Brabender Loss-In-Weight Feeders (Continued)

Brabender SiloTray Feeder

The Brabender SiloTray Feeder is a vibratory bin activator and a metering feeder in one. Suspended from a load cell mounted bin by means of its flexible hanger arms and equipped with variable vibration motors, the unit allows loss-in-weight metering directly from the bin and additionally ensures reliable bin discharge without bridging or particle deterioration. The Brabender SiloTray Feeder can be used for all flowable bulk ingredients without hygroscopic, sticky or floodable properties, so - for instance - for pellets, powders, fluffs, glass fibers, film chips and similar media.

For more information, please visit:

https://edir.bulk-online.com/profile...echnologie.htm

http://www.google.com/search?hl=de&c...btnG=Suche&lr=

Attachments

■

Brabender Loss-In-Weight Feeders (Continued)

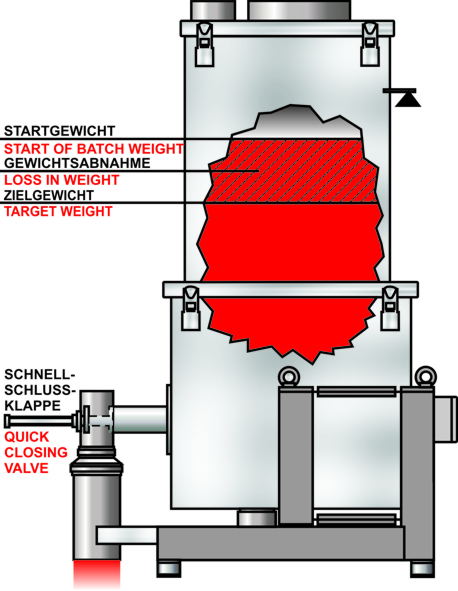

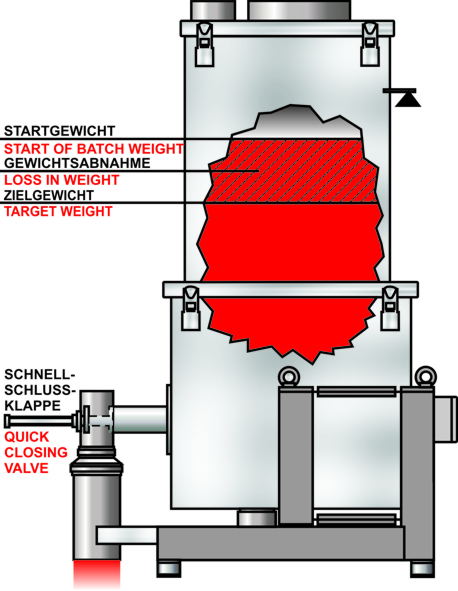

Loss-in-Weight Batching

Discontinuous loss-in-weight bulk ingredient batching can be performed by all Brabender loss-in-weight feeders due to special batch programs for the Brabender feed controllers. After the batch size (setpoint) has been entered, the controller deducts the batch weight from the current hopper weight, thus caculates the target weight and stops the feeder automatically as soon as the target weight is reached. Switching over from coarse to fine flow near the end of the batching cycle and the concluding dribble feed phase ensure utmost batching accuracy. Another batching mode is the so-called "A.R.T." principle ("Automatic Rate Turndown"). In this case the feed rate is turned down in a curve function until it reaches the switch-off point.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1246-brabender-technologie.htm" target="blank">https://edir.bulk-online.com/profile...echnologie.htm

href="http://www.google.com/search?hl=de&client=safari&rls=de-de&q=Brabender+site%3Abulk-online.com&btnG=Suche&lr=" target="blank">http://www.google.com/search?hl=de&c...btnG=Suche&lr=

Attachments

■

Brabender Loss-In-Weight Feeders (Continued)

Nomenclature

Although generally called loss-in-weight feeders, these gravimetric metering feeders are sometimes found under varying names in industry and literature. However, all terms refer to the same type of feeders. Hereinafter you will find a brief survey of the most frequent variants:

differential feeders | loss-in-weight differential feeders | loss-in-weight feeders | loss-of-weight feeders | weight loss differential feeders | weight loss differential weigh feeders | weight-loss feeders | weigh-feeders (refers to all gravimetric feeders, not only loss-in-weight feeders)

For more information, please visit:

https://edir.bulk-online.com/profile...echnologie.htm

http://www.google.com/search?hl=de&c...btnG=Suche&lr= ■

Brabender Loss-In-Weight Feeders (Continued)

Accessories: Brabender JetFilters

Brabender JetFilters are low maintenance air filtering systems featuring fully automatic self-cleaning by compressed air pulses and are applied as dust separators for air streams escaping from continuous and discontinuous bulk ingredient metering feeders, for instance loss-in-weight feeders, due to air displacement during refilling. The filter material in the filter cartridge, compactly arranged though offering a huge filtering surface, ensures optimum surface exposure to the air stream and thus highly efficient filtering. At the same time the system features low flow resistance and thus constant air throughput avoiding differential pressure. If, however, differential pressure is required - for instance in case of protective gas blanketing in the bulk ingredient hopper - closed versions are optionally available. Filter cleaning is effected fully automatically by compressed air pulses while feeding the raw material caught in the filter back into the metering feeder and thus into the production process. All Brabender JetFilters are explosion-proof as per ATEX II 2GD/2GD.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1246-brabender-technologie.htm" target="blank">https://edir.bulk-online.com/profile...echnologie.htm

href="http://www.google.com/search?hl=de&client=safari&rls=de-de&q=Brabender+site%3Abulk-online.com&btnG=Suche&lr=" target="blank">http://www.google.com/search?hl=de&c...btnG=Suche&lr=

Attachments

■

Brabender Loss-In-Weight Feeders (Continued)

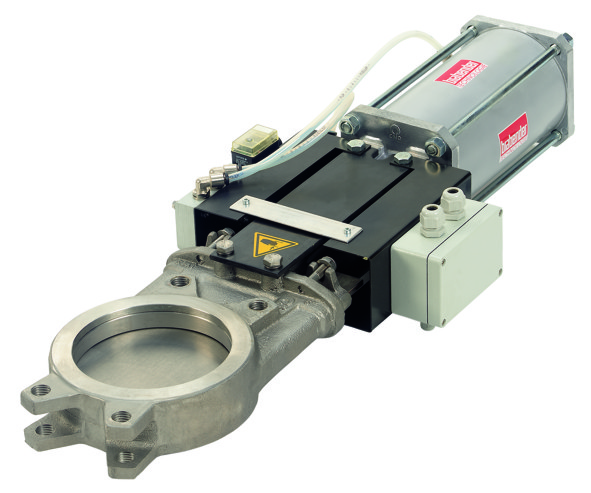

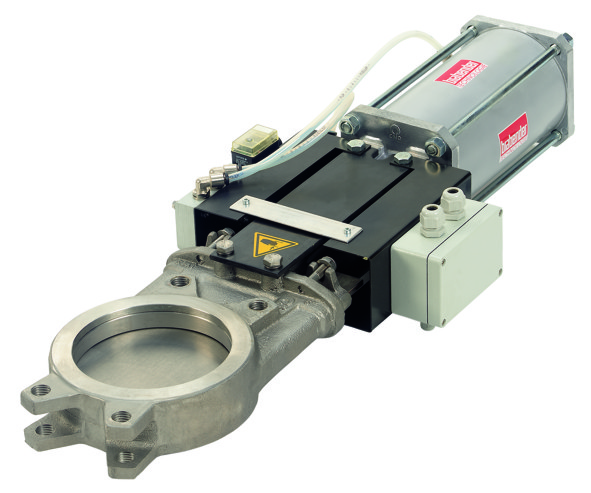

Accessories: Brabender Flat Gate Slide Valves

Brabender flat gate slide valves with double-acting pneumatic drive are used as automatic refill valves for loss-in-weight feeders, serving to unblock the ingredient stream for feeder refilling and to shut off the refill device again at the end of the feeder refill phase. Their short opening and closing times make them particularly suitable for this task. Of course the slide valves can also be used for any other application requiring reliable and quick release and interruption of bulk ingredient streams.

Depending on the required flow volume and the respective pipeline diameters, Brabender flat gate slide valves are available in standard sizes ranging from 65 to 400 mm diameter. Upon request, further diameters can be supplied. The slide valves are supplied fully assembled including a 5/2 way solenoid valve. All parts in touch with the ingredient are made of stainless steel.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1246-brabender-technologie.htm" target="blank">https://edir.bulk-online.com/profile...echnologie.htm

href="http://www.google.com/search?hl=de&client=safari&rls=de-de&q=Brabender+site%3Abulk-online.com&btnG=Suche&lr=" target="blank">http://www.google.com/search?hl=de&c...btnG=Suche&lr=

Attachments

■

How Much Does This Cost In Gbp(£)

How much does this cost in GBP(£)

For feeding of fine-grained ingredients at rates of a few grams per hour Brabender offers the Brabender RotoTube Micro Feeder, a loss-in-weight feeder in miniature equipped with a rotary tube with an integrated particle guidance system. Particularly if granules are metered, individual grains can be dispensed virtually one after the other. An infinitely variable tilting system allows to tilt the tube for further feed rate adjustment. The loss-in-weight feeder uses the digital high-tech weighing system DigiMASS-2 featuring two vibrating wires.

For more information, please visit:

https://edir.bulk-online.com/profile...echnologie.htm

http://www.google.com/search?hl=de&c...btnG=Suche&lr=

■

Brabender Loss-In-Weight Feeders (Continued)

Loss-in-Weight Feeders for the Food Industry

Developed in close cooperation with leading food companies, the "Brabender Food Line" is a series of special loss-in-weight feeders in "Hygienic Design" for the food industry strictly conforming to all applicable food standards, guidelines and recommendations (DIN EN 1672-2, EHEDG, FDA, etc.).

During development, great importance was attached to quick and easy cleanability and particularly to the prevention of contamination. As a result, all feeders of the "Brabender Food Line" feature a broad variety of measures taken to achieve this goal, e. g. smooth stainless steel surfaces, non-porous and ground welding seams without joints, avoidance of cavities and hollow spaces, rounded edges and corners, FDA approved materials and many more.

The "Brabender Food Line" comprises hygienic design versions of proven Brabender loss-in-weight feeders, so - for instance - the well-known FlexWall®Plus feeder with its flexible hopper, screw feeders with stirring agitators, loss-in-weight scales with vibrating tray feeders and the Brabender DualTray feeder with mass flow feed module. The array is supplemented by the Brabender weigh-belt feeder in "Hygienic Design". With this line of metering feeders Brabender can offer suitable feeding solutions for virtually all kinds of bulk ingredients processed in the food industry.

Brabender Technologie is one of the members of the European Hygienic Engineering & Design Group (EHEDG).

For more information, please visit:

href="https://edir.bulk-online.com/profile/1246-brabender-technologie.htm" target="blank">https://edir.bulk-online.com/profile...echnologie.htm

href="http://www.google.com/search?hl=de&client=safari&rls=de-de&q=Brabender+site%3Abulk-online.com&btnG=Suche&lr=" target="blank">http://www.google.com/search?hl=de&c...btnG=Suche&lr=

Attachments

■

Brabender Loss-In-Weight Feeders (Continued)

Brabender FlexWall®Food Feeder in "Hygienic Design"

The Brabender FlexWall®Food Feeder, one of the loss-in-weight feeders from the "Brabender Food Line", is the "Hygienic Design" version of the well-known Brabender FlexWall®Plus Feeder with its paddle agitated flexible hopper. Depending on the application, a package of option allows variable adaptation to the respective requirements and thus offers utmost flexibility. Special FDA approved PUR hoppers, stainless steel motor covers, motors with food-proof and acid-resistant painting, base plates, junction boxes, chassis for sub-assemblies and load cells made of stainless steel, downspouts and flexible connection sleeves made of FDA approved PUR and directional hopper grinding are only a few of the options selectable beside the standard features characterizing all feeders from the "Brabender Food Line" anyway.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1246-brabender-technologie.htm" target="blank">https://edir.bulk-online.com/profile...echnologie.htm

href="http://www.google.com/search?hl=de&client=safari&rls=de-de&q=Brabender+site%3Abulk-online.com&btnG=Suche&lr=" target="blank">http://www.google.com/search?hl=de&c...btnG=Suche&lr=

Attachments

■

Brabender Loss-In-Weight Feeders (Continued)

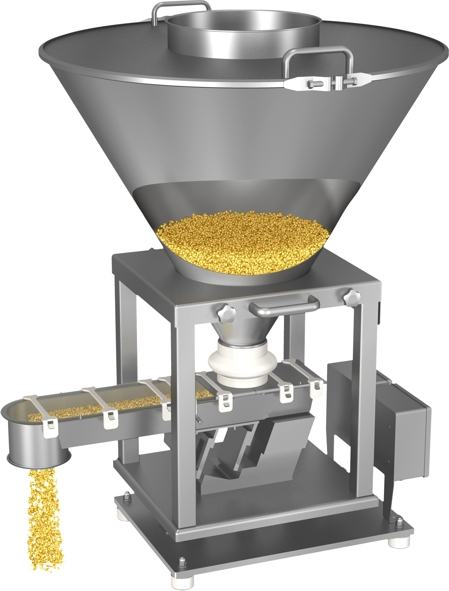

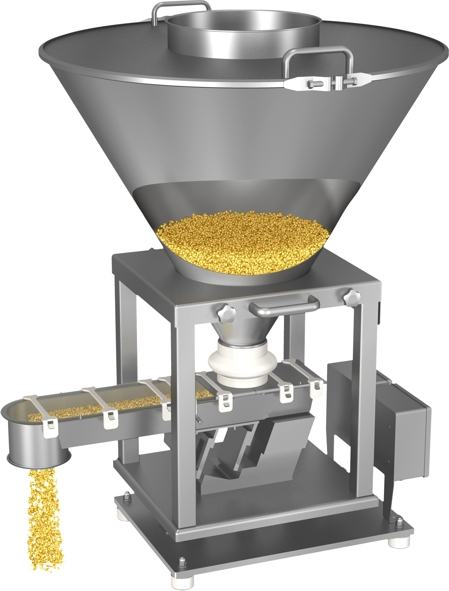

Brabender Screw Feeders in "Hygienic Design"

Another loss-in-weight feeder from the "Brabender Food Line" for the food industry is the hygienic design version of the Brabender loss-in-weight scale with stirring screw feeder. Parts in touch with the ingredient made of stainless steel, quick release locks on the extension hopper and hopper cover as well as the quick clamping fastener on the screw tube for easy dismounting and cleaning, the full enclosure of load cell, screw motor and agitator motor, the junction boxes made of stainless steel and the flexible connection sleeves made of FDA approved PUR are only a few of the particular hygienic design features qualifying this loss-in-weight feeder for the food industry beside all the other standard features characterizing the metering feeders from the "Brabender Food Line".

For more information, please visit:

href="https://edir.bulk-online.com/profile/1246-brabender-technologie.htm" target="blank">https://edir.bulk-online.com/profile...echnologie.htm

href="http://www.google.com/search?hl=de&client=safari&rls=de-de&q=Brabender+site%3Abulk-online.com&btnG=Suche&lr=" target="blank">http://www.google.com/search?hl=de&c...btnG=Suche&lr=

Attachments

■

Brabender Loss-In-Weight Feeders (Continued)

Brabender Vibrating Tray Feeder in "Hygienic Design"

The Brabender loss-in-weight feeder with vibrating tray in "Hygienic Design" is one of the loss-in-weight feeders from the "Brabender Food Line". Beside the hygienic design features complying with the relevant standards, guidelines and recommendations for the food industry (DIN EN 1672-2, EHEDG, FDA, etc.) that all feeders from the "Brabender Food Line" have in common, this gravimetric metering feeder is distinguished by some particularly sophisticated quick cleaning features. So all parts in touch with the ingredient (hopper, vibrating tray, downspout and flexible sleeves) can be dismounted from the drive unit without tools, while the captive fastening elements remain connected with the feeder. Free cleaning access to the load cell is also ensured. The Brabender loss-in-weight feeder with vibrating tray has no rotating parts and is thus particularly recommendable for damageable ingredients.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1246-brabender-technologie.htm" target="blank">https://edir.bulk-online.com/profile...echnologie.htm

href="http://www.google.com/search?hl=de&client=safari&rls=de-de&q=Brabender+site%3Abulk-online.com&btnG=Suche&lr=" target="blank">http://www.google.com/search?hl=de&c...btnG=Suche&lr=

Attachments

■

Brabender Loss-In-Weight Feeders (Continued)

Brabender DualTray Feeder in "Hygienic Design"

The hygienic design version of the Brabender DualTray Feeder is one of the loss-in-weight feeders from the "Brabender Food Line" developed in compliance with applicable standards, guidelines and recommendations for the food industry (DIN EN 1672-2, EHEDG, FDA, etc.). Being a vibratory vertical mass flow feeder without rotating parts it is perfectly suitable for damageable ingredients, ingredients with differently sized grains, lumpy media and fibers, particularly for batching processes. Dismantling and cleaning the Brabender DualTray Feeder is extraordinarily easy. After quick disconnection of the feed unit from the vibratory drive unit the feed modules and the outlet cone (all interconnected by quick clamping rings) can be removed.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1246-brabender-technologie.htm" target="blank">https://edir.bulk-online.com/profile...echnologie.htm

href="http://www.google.com/search?hl=de&client=safari&rls=de-de&q=Brabender+site%3Abulk-online.com&btnG=Suche&lr=" target="blank">http://www.google.com/search?hl=de&c...btnG=Suche&lr=

Attachments

■

Brabender Loss-In-Weight Feeders (Continued)

Used Loss-in-Weight Feeders in Perfect Condition

Almost always Brabender Technologie has a well-assorted stock of used loss-in-weight feeders, showroom feeders and exhibition feeders, including the pertinent single and multiple feeder control systems. All feeders have been thoroughly refurbished and are in absolutely perfect condition. The Brabender specialists will be pleased to inform you about feeders currently on sale and to advise you of their according performance data and fields of application.

Information about how to make contact can be obtained on the website of Brabender Technologie by clicking on the "Used Feeders" link in the navigation bar at the top. To get the company's website address, please use the first of the links mentioned below.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1246-brabender-technologie.htm" target="blank">https://edir.bulk-online.com/profile...echnologie.htm

href="http://www.google.com/search?hl=de&client=safari&rls=de-de&q=Brabender+site%3Abulk-online.com&btnG=Suche&lr=" target="blank">http://www.google.com/search?hl=de&c...btnG=Suche&lr=

Attachments

■

Brabender Loss-in-Weight Feeders

Brabender Loss-in-Weight Feeders

Brabender Technologie is one of the world's leading manufacturers of loss-in-weight feeders. Due to its world-wide sales, consulting and service network and with its headquarters in Germany, North America, Dubai, Russia, India and China the company is present all over the globe.

To accomplish the goal of being able to offer an optimum feeding solution for any bulk ingredient conceivable at high quality standards and at a favourable cost-performance ratio, Brabender supplies a variety of loss-in-weight feeder models ranging from universal metering feeders for virtually all kinds of bulk ingredients to special solutions for bulk ingredients with extraordinary or critical flow characteristics. So the feed mechanisms used in the loss-in-weight feeders comprise - for instance - single screws, twin screws, vibrating trays, vibratory mass flow feeders, rotary tubes, etc.

Brabender loss-in-weight feeders are manufactured in strict accordance with DIN ISO EN 9001 quality assurance standards. Component groups complying with the latest technical state, partly patented and conforming to obligatory industrial standards ensure reliable function and long life-times, beginning with with sealings, motors, gearings, electrotechnical components and ending with highly sophisticated electronics in the digital load cells and the Congrav® microcomputer controllers.

The group of companies supplies loss-in-weight feeders to the plastics producing and plastics processing industries, to the chemical, pharmaceutics and cosmetics, food, pet food, detergent, construction material, ceramics and glass industries and to all other industries processing bulk ingredients.

For more information, please visit:

https://edir.bulk-online.com/profile...echnologie.htm

http://www.google.com/search?hl=de&c...btnG=Suche&lr=

Attachments

flexwall plus (JPG)

ddw-dsr (JPG)

ddw-ddsr (JPG)

dvt (JPG)

■