Smartmillcontrol (Continued)

(continued)

In the past these requirements were fulfilled by means of “classical“ automati-on systems and closed loop controllers. Over the years, experience has shown, that “classical“ controller solutions don‘t fit to contemporary demands.

SmartMillControl is designed as a Fuzzy Expert-System for advanced and so-phisticated control of grinding plants. Usage of advanced technologies and new methods enables SmartMillControl to achieve significantly better control of mills. A single control block can take several inputs and outputs into account, leading to much better control results.

Smooth and stable operating conditions and optimisation of throughput are primary goals of control startegies.

SmartMillControl is based on highly developed software tools and building blocks. Data exchange to the process / grinding plant is performed by means of standardized industrial interfaces.

Consistent and consequent usage of open system interfaces enables easy connection to all automation systems being used in todays‘ cement industry .

Due to the highly modular design of SmartMillControl investment is kept low.

Attachments

■

Smartmillcontrol (Continued)

(continued)

The advantages:

• Enhanced throughput by at least 5% Guaranteed !!

• Specific energy consumption reduced

• Reduction of ball charge additions by up to 50%

• Precise and fast closed loop control

• Reduced stress for operating personel, due to smooth operation

• Reduced maintenance cost

• Less wearout

• Reduced downtimes

• Lower cost as competing products at the same level of functionality

• Fast Return of Investment

Features for optimisation:

• Fully automatic start-up and shut down

• Automatic change of cement grade

• Control strategies can be completely customised

• Self optimising control schemes

• Intelligent management of external disturbance,

e.g. change of grindability, loss of grinding aid . . .

Control strategies:

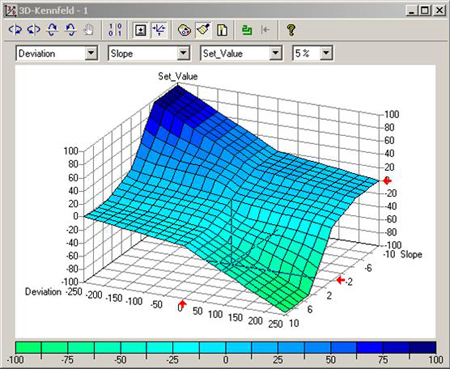

Due to the fact that SmartMillControl is designed as a configurable Fuzzy Ex-pert system, new possibilities to control grinding plants arise (e.g. use the sepa-rator to control returns, which then in-fluences the level in the mill).

Simple PID-controller can only use a single input to calculate a single out-put only to be used for the loop control. SmartMillControl‘s Fuzzy-technology processes a multitude of inputs. The system can be tuned to follow different targets.

This flexibilities facilitate new innovative solutions for grinding plant controllers, which render much better results, than classical PID-controllers.

Of course, modern versions of the “classical“ strategies:

Feed = constant

returns = constant

can be chosen.

When doing so, the advantages of the Fuzzy-Expert system are preserved, namely the consideration of several inputs, which might be contradictory.

Attachments

■

Smartmillcontrol (Continued)

(continued)

How does it work?

SmartMillControl is based on a database, which inherits Fuzzy-technologies for process optimisation.

Based on an ongoing rating of the process, the current state of the facility is evaluated.

Sophisticated algorithms, which inherit KIMA‘s and the customers experience, then calculate new parameters for subordinate control systems.

For the acquisition and long term storage of process data, the database is used also. A flexible and very easy to use software system for the management of process data, display of trends analysis and reporting is available.

As an option a recipe management system can be added.

No special prerequisites are neccessary for the integration of SmartMillControl. The software is running on a standard PC, which can very easy be connected to all automation systems, which are used in plants. There is only a low effort to connect SmartMillControl to the automation system. The investment is significantly lower as compared to competing systems.

SmartMillControl can even be enhanced by the following options:

• Combined with SmartFill the “electronic ear“ for cement mills, SmartMillControl operates at optimum conditions. Using both systems you drive your mill at a predefined level of quality at ist optimum level.

• Controlling the temperature inside of the mill, using the temperature option of SmartFill to measure the cement temperature directly in the diaphragma.

• Control of air flow and air temperature at the separator.

• Control of chemical composition according to laboratory data.

KIMA Echtzeitsysteme GmbH was founded 1996 in Jülich Germany. A highly motivated team of engineers, software developers, physicists and technicians is working on high performance solutions and building blocks, which can be tailored to be used in various process applications.

KIMA is a highly qualified contact for all puposes of advanced measurement and control systems for the process industries.

The cement industry is one focal point of our work. KIMA Fuzzy-logic controllers are operating and controlling mills, complete grinding plants and kilns for more than 10 years. They achieve highest efficiency, optimum availability and smooth operation, thus enabling high product quality and durability of machinery.

The market launch of „SmartFill“, a high perfomance, high precision level measurement system for ball mills in 2003 was a milestone in the history of the company.

KIMA solutions are also used in food, chemical, waste water industries, as well as in mechanical engineering, and for oil production.

For more information, please visit:

href="https://edir.bulk-online.com/profile/8884-kima-echtzeitsysteme.htm" target="blank">https://edir.bulk-online.com/profile...eitsysteme.htm

Attachments

■

SmartMillControl

SmartMillControl

Enhanced throughput and reduced cost due to modern closed loop control of grinding plants!

There is an ongoing pressure on the cement industry for improvement. New requirements for quality and cost reduction demand better production methods.

KIMA meets these challenges by developing systems for the cement industries based on advanced and proven technologies.

SmartMillControl - the Fuzzy-Expert-system

SmartMillControl is a modern control system für grinding plants. The Fuzzy-Expert-system performs much better than the “classical“ closed loop controls (PID) or even rule based expert systems.

Based on many decades of experience with advanced closed loop controls and optimisation of mills and grinding plants, SmartMillControl enhances efficiency and durability of grinding systems significantly.

Cement production nowadays needs high availabilty of machinery, reduction of cost and enhancement of through-puts.

Attachments

kima-1 (JPG)

■