Help

Hi,

You can use belt conveyor.Special belt with embossment recommanded.like bladed belt.

You can also use bucket conveyor,but I prefer to use belt because of its smooth conveying ■

Re: Conveyor For Wood Blocks

To prevent bridging at the feed point the recommended pratice says the opening should be a multiple of the largest lump handled. Factors range from 7 to 5. With your light product & large lump size the necessary opening strongly mitigates against a belt conveyor to carry 1 tonne per hour.

The rest of your process needs to be revealed to the forum before a realistic suggestion can be made eg. how are the blocks produced, what is the upstream take off procedure, is it random or a precise machine output? ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Conveyor For Wood Block

Dear Sir,

I used trough belt conveyor for handling wood of 30mm in BHUTAN FERRO ALLOY plant receintly.

Regards.

A.Banerjee ■

Wood Block Conveying

1 m3 per hour is a very small quantity.

You can use a skip hoist to do the work. Lifting height is 6 m. OK for a skip hoist. ■

Conveyor For Wood Blocks Up To 2 Ft

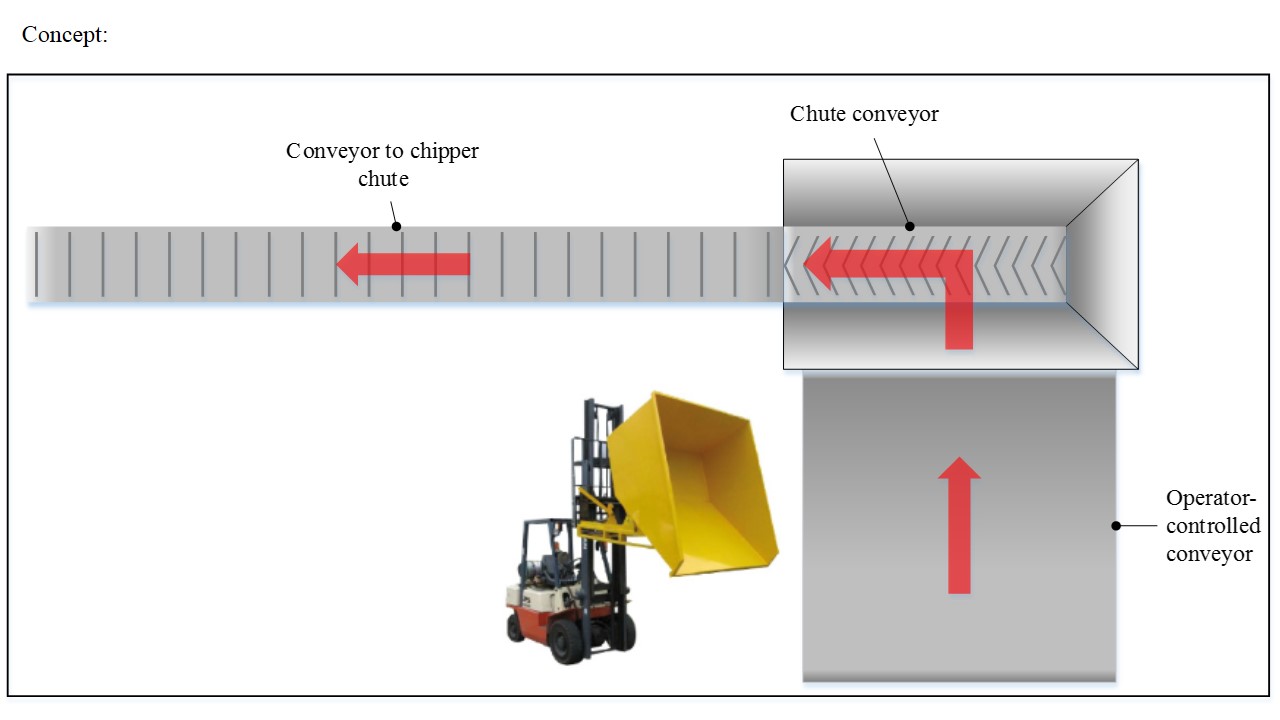

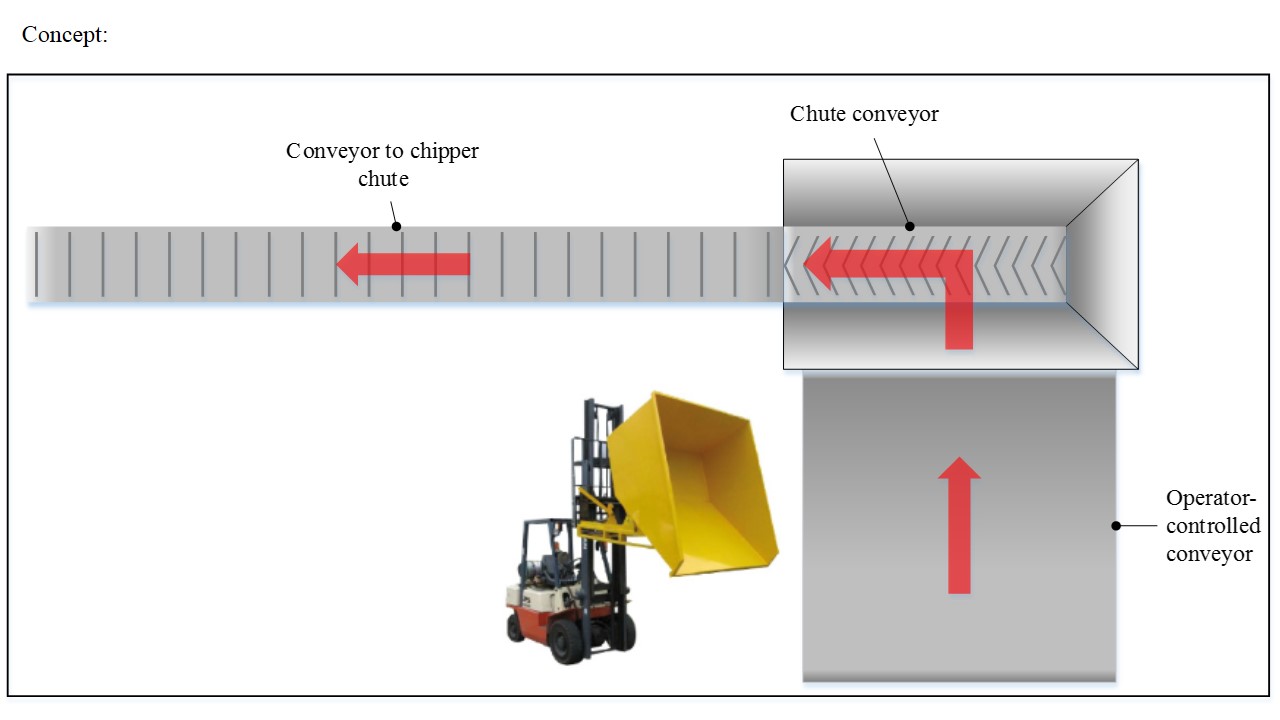

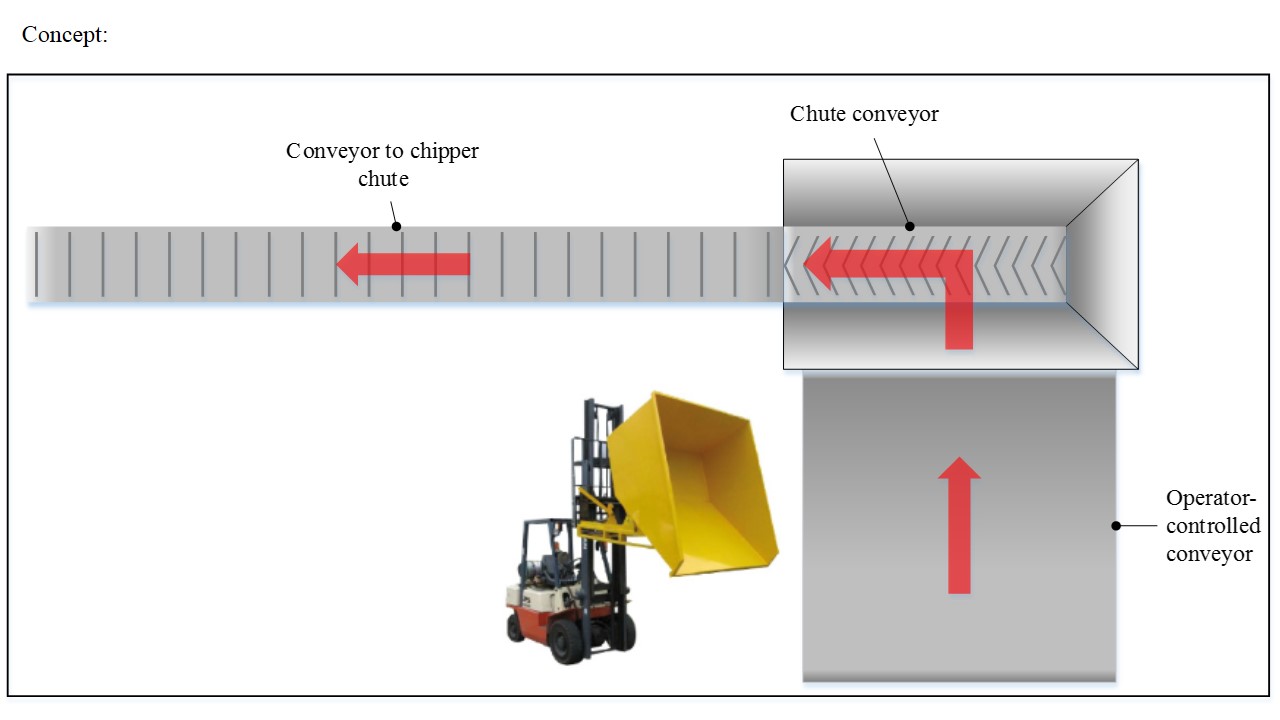

My team and I are designing a machine as project for University. The machine has to take wooden blocks ranging from 1-3 inches square in cross section, and up to 2 feet long. Using a forklift we will unload a bin onto a wide conveyor (1.5 m) which the operator controls, dropping bit by bit into a cute which has a conveyor underneath. This conveyor then deposits the blocks onto a sloped conveyor (about 20°) which elevates the blocks 3 meters and drops them into the chipper chute, at about 6 m3/hour

My main concern is if it will even work; transporting such large pieces on a conveyor. Granted most of the pieces are 1 ft or shorter. But we'll still get more often than not, a 2 footer. I'd say about 15% are over 1.5 ft.

I suspect it will tend to catch on the sides of the conveyor. Could this be solved by making the conveyor a little wider than 2 ft? Also, what kind of cleat would the lifting conveyor need so the blocks don't fall backwards?

Any help would be very appreciated. Attached is a picture of the concept we came up with.

href="https://forum.bulk-online.com/attachment.php?attachmentid=39860&d=1401816598" id="attachment39860" rel="Lightbox82858" target="blank">■

Supply Of Conveyor Belts

dear All

I caqn supply you all and any type of conveyor belts

Please provide your requirements for us to give a good quote

Regards

Vivsea ■

Need Another Project.

My main concern is if it will even work; transporting such large pieces on a conveyor. Granted most of the pieces are 1 ft or shorter. But we'll still get more often than not, a 2 footer. I'd say about 15% are over 1.5 ft.

I suspect it will tend to catch on the sides of the conveyor. Could this be solved by making the conveyor a little wider than 2 ft? Also, what kind of cleat would the lifting conveyor need so the blocks don't fall backwards?

Any help would be very appreciated. Attached is a picture of the concept we came up with.

Why not utilise the conveyor space to drive the forklift straight to the chipper? At 6m3h-1 the problem is what to use the forklift for the rest of the time. Who thinks these things up for you? ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

We Deserve Better

Vivsea,

We might need a conveyor to remove the crap you have started to produce in your sales drive. ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Re: Conveyor For Wood Blocks

Hello,

Suggest to clarify 3 dimensions of the wooden blocks along X, Y and Z coordinates . Approximate dimensions are good enough. There appears to be some ambiguity whether these are planks of 30 to 100 mm thickness or these are of cuboid shape where dimensions along any coordinate is less than 100 mm.

Regards,

Ishwar G. Mulani.

Author of Book: Engineering Science And Application Design For Belt Conveyors (new print November, 2012)

Author of Book: Belt Feeder Design And Hopper Bin Silo

Advisor / Consultant for Bulk Material Handling System & Issues.

Pune, India.

Tel.: 0091 (0)20 25871916

Email: conveyor.ishwar.mulani@gmail.com

Website: www.conveyor.ishwarmulani.com ■

Big Timber In Chutes

CDI am willing to offer a Discrete Element Model (DEM) of your intended flow. This is not a design only simulation of your set.

CDI will publish this flow simulation on the forum, to allow all to visualize what DEM can do.

To accept this free offer you must provide:

1. Particle (timber) sizes and shapes you wish to model - 1 x2x24", 2x2x12", etc. for a mix that satisfies the design and tonnage over a 20 second simulation cycle.

2. Conveyor sizes, belt speeds. trough shapes, et al in AutoCAD format or Inventor or Solidworks

3. Chute and skirt sizes (interior flow surface) in AutoCAD or Inventor format...

4. We orient feed pattern per our random distribution method to the discharge bucket into the receiving hopper

WE will post the result on this forum in AVI like format to allow visual animation. It may take a week or so. No $$$ obligation. We may wish to publish on YouTube or other venues. ■

Big Timber In Chutes Part Ii

My main concern is if it will even work; transporting such large pieces on a conveyor. Granted most of the pieces are 1 ft or shorter. But we'll still get more often than not, a 2 footer. I'd say about 15% are over 1.5 ft.

I suspect it will tend to catch on the sides of the conveyor. Could this be solved by making the conveyor a little wider than 2 ft? Also, what kind of cleat would the lifting conveyor need so the blocks don't fall backwards?

Any help would be very appreciated. Attached is a picture of the concept we came up with.

------------------------------------------------------------------------------------------------

There is a way to create a more selective/proper flow ( my idea) to show the event works. If it works, I will make it part of the published animation. This is pro-bono. ■

Conveyor for wood blocks

Looking for a conveyor which can handle wood blocks of > 30 and < 100 mm size. The conveyor would have to lift the blocks to a height of approx. 6meters. The cap. reqd is 1 mt/hr. Wood blocks have a bulk density of 250-300 kg/cu.m.

How do I eliminate the likely flow problems in wood block feeding point? ■