Ash Silos

Hi chetan,

You are right to ask about designing for ash storage. Ash can be a bastard product to handle. It sticks to vertical surfaces, bottom ash is course, fly ash is fine, it can come in lenses with a wide variety of flow properties.

One way to approach the problem is to get on the phone to the Maintenance Engineer at your nearest Powerstation. Talk to the guys who battle with the stuff on a daily basis. That way you will be in a far better position to know if the technical rep is trying to sell you some bullshit.

Regards - Sgt John.rz

www.latviantourists.com.au ■

Fly Ash Silo

There is a simple yet extremely effective solution to prevent the from clinging to the silo walls and to ensure smooth, even discharge - Primasonics Acoustic Cleaners. However, first you must clean out your silo. The safe way to do this is to either hire an experienced silo cleaning company or to purchase our safe, remote silo cleaning system - The Gyro Whip. Please take a look at the following link for inflomation on this effective, remote silo cleaning system which eliminated the need for man entry.-

http://www.primasonics.com/silocleaning.htm

Then, once clean, install the correct model of Acoustic Cleaner on top. Sound waves will prevent the cement particles from bonding and ensure mass flow. Again, please take a look at the following link at -

http://www.primasonics.com/acousticcleanersrange.htm

On our web site you will also find a silo questionnaire form which you can either complete on-line or download. The link for this form is -

http://www.primasonics.com/siloform.htm

Alternatively you can contact me on - sound@primasonics.com

Donald F Cameron

Primasonics International Limited ■

Re: Seeking Advoice

href="showthread.php?p=32045#post32045" rel="nofollow">

Please let me know what precautions to be taken to design a silo for ash i.e. material of silo, slope of wall, lining if any for coal and bagasse ash?

Thanking you

chetan

Dear Chetan,

it is really to consider the design to avoid bridging and ratholing in ash silo.

sonic horn by compressed air could solve the problem, and get smooth material flow. sonic wave could break the bonding of particles and ensure good flowability.

above picture is the utilization sonic horn in silo/hopper.

get more info from here:

Attachments

■

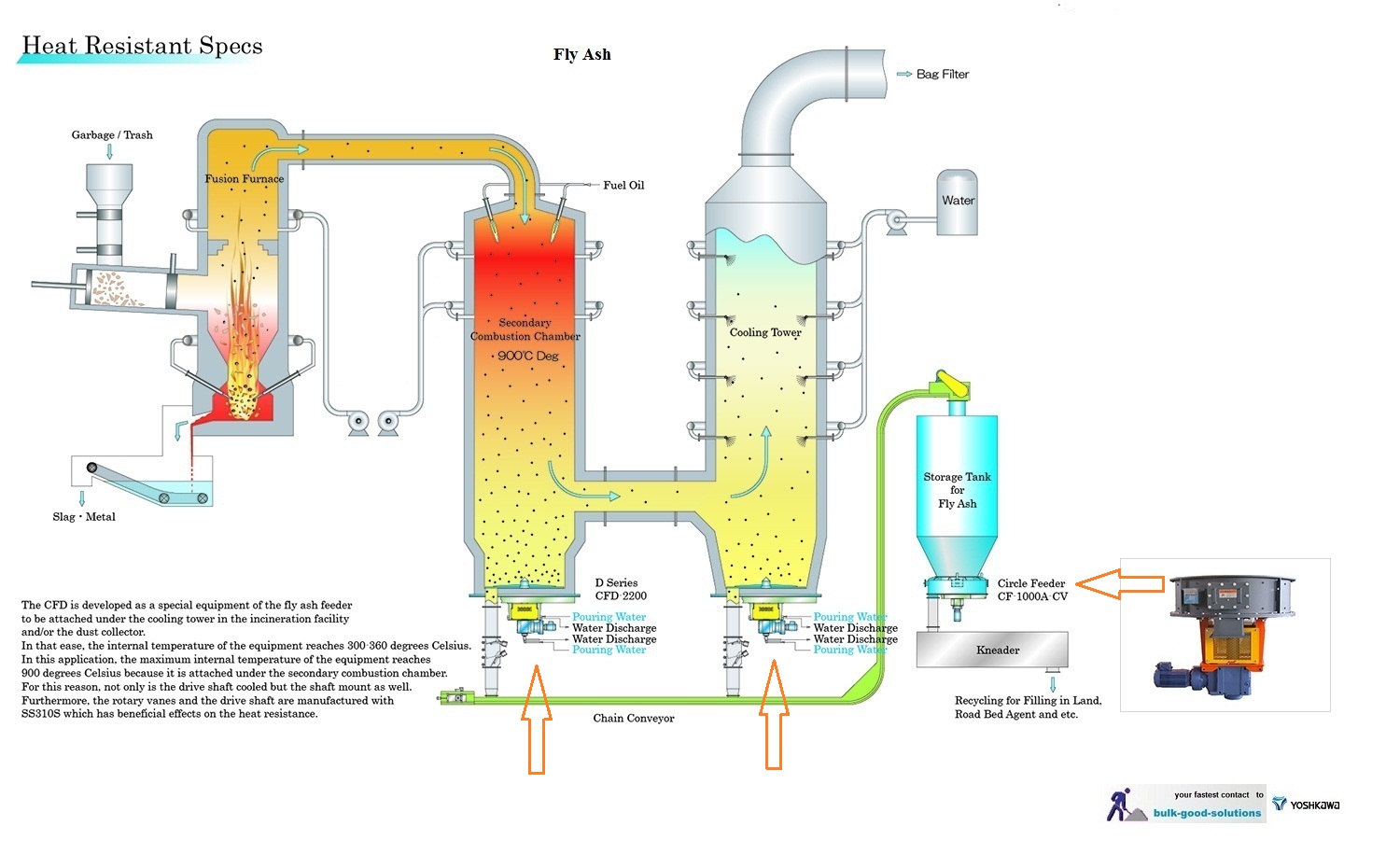

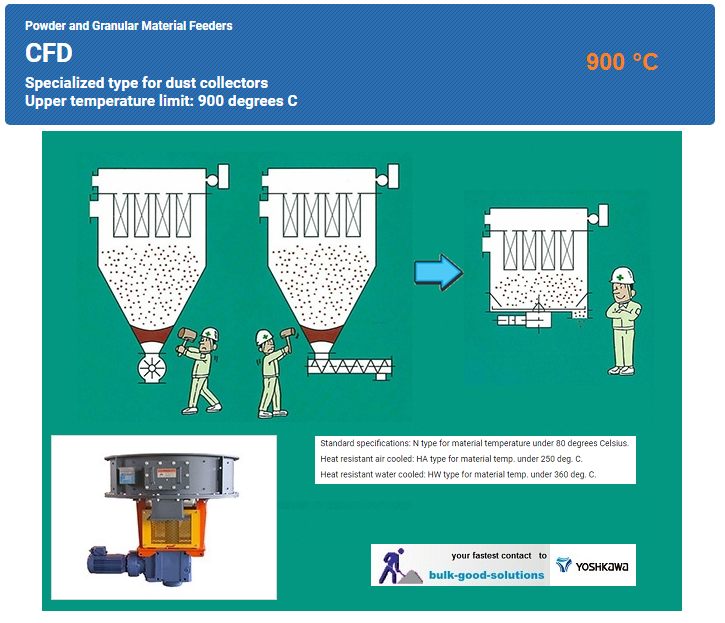

Circke Feeder Discharge

One experienced manufacturer offers Circle Feeder.

The advantage is the bigger discharge surface what means in avoid a cone-bin: avoids that the material sticks in a bin an so avois ratholes or bridging.

I add two pictures aimed to hot fly ash, but it works to show the discharge cocept

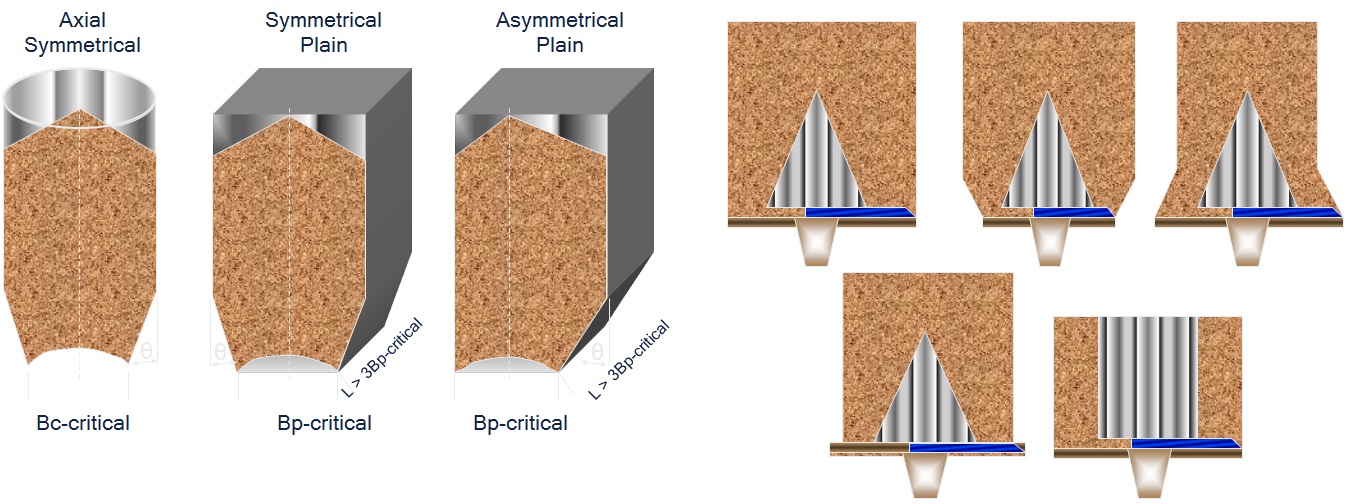

Also the silo design is important

href="https://forum.bulk-online.com/attachment.php?attachmentid=48077&d=1584035237" title="Name: silo-discharge-solutions.jpgViews: 102Size: 204.8 KB">silo-discharge-solutions.jpg ■

Seeking advoice

Dear Sirs,

Please let me know what precautions to be taken to design a silo for ash i.e. material of silo, slope of wall, lining if any for coal and bagasse ash?

Thanking you

chetan ■