Re: Reclaiming Of Stacked Coal Without Using Any Underground Ho…

If you look up the link below you will get a picture of this totally impressive machine.

http://www.stamler.co.uk/reclaimfeeder.htm ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Reclaiming Of Stacked Coal

Thanks for the plug John.

Prashant, if you want any further information on our Reclaim Feeders please let me know.

Thanks ■

Coal Reclaiming

Dear Sir

Depending on your required capacity, we may be able to assist. Please consider a complete coal yard(equipment only). Includese (2) Stacker-Reclaimers each rated 4000/1500tph, all conveyors,sorting, sampling, dust suppression, truck/train load out, control room.

We would be pleased to send you photos and descriptions.

Sincerely,

Al Goodmundson

Email: norsequip@sasktel.net

Phone: (306)-664-7260 ■

Recliaming Of Stack Coal

Dear Mr. Prashant,

Please write to Oldenburg, Stamler,UK for reclaim feeder.Mail is admin@oldenburggroup.co.uk

Regards.

A.Banerjee ■

Re: Reclaiming Of Stacked Coal Without Using Any Underground Ho…

Originally posted by Prashant

Hello!

At our thermal plant we're enhancing coal handling facilities for meeting our future needs and we're looking for some low cost, short time construction solutions and While surfing on net for the same I came across this piece of information about feeding of coal without using underground hopper.

"15/11/2004 - The management of the emergency in a coal yard

the best solution is to employ a Stamler/Magaldi Reclaim- feeder as done byEndesa Power Plant from Fiumesanto in Sardinia.

This year Endesa Power Plant, during its full productive period, had the necessity to load the boiler ‘s bunkers but the onlystacker reclaimer available was operating for the coal storage.

The customer needed to:

Transfer over 800 coal t/h from the coal yard to the bunkers

Speed up the coal handling inside the yard (by using the existing means)

Avoid the building of new infrastructures withconsiderable cost and relevant downtime

Keep unalteredthe volume capacity of the coal yard

Magaldi engineers set and carried out a project, the first in Italy, in order to give a solution to the above listed requirement sand, finally, the use of a Reclaim feeder was decided.

The Stamler/MagaldiReclaim-feeder is a compact and sturdy equipment which offers multiple advantages:

Easy installation

It only requires solid and level ground conditions for installation.

Eliminate Costly Civil Work and Site Preparation

The hopperless design allows material to be pushed by dozers or vertically discharged from front-end loaders, trucks, clam shell buckets and excavators directly onto the integral drag conveyor

Efficiency and reliability

Severalreferences worldwide show that the Stamler/Magaldi Reclaim Feeder is custom designed and built to suit heavy, operating, reachingconditions up to 3200 coal t/h capacity. """""

Can some one give me the details of this Stamler/ Magaldi reclaim feeder which uses NO underground hopper for feeding of coal?

Having been involved with the WR Stamler belt feeder breakers for 22 years I will gladly offer my experience with them.

This will be third time I have tried to post this so hopefuly it will stick.

The WR Stamler company was formed when Mr. Stamler was asked to build an underground raill car spotter for a coal mine and the company grew from there.

The WR Stamler Feeder Conveyor has its roots in the design for a mobile underground primary crusher that Mr. Stamler designed for coal mines.

The design of the feeder allows it to be moved to where it is needed to reclaim materials.

The feeder can be designed with skids or even track mounting,

track mounting saves time in setting up over conveyors and a prime mover is not required to move it as long as it has access to electrical power to operate the crawler hydraulic drive via trailing electrical cable which is going to be required anyway.

The feeder can be built with a hopper or without a hopper.

The advantage of a hopper outweighs a hopperless unit IN MY OPINION as it is easier to keep clean and inspect the tail shaft assembly, grease tensioners for the drag conveyor and the drag chain flight conveyor and reduces the damage to the bed and sides of the belt feeder from a loader or end dump hitting the sides of the feeder.

Using a tall front end loader/crawler excavator or a clam shell bucket equiped crawler crane allows for easy placement of ores in the hopper, using a loader with a side tipping bucket makes it even simpler as it is easily loaded at the end of the feeder as well.

A very good example of this is the WR Stamler belt feeder breaker model owned by The Detroit Salt Company in Detroit, Michigan USA the belt feeder breaker has very high sides and an open end for loading the feeder. the high sides reduce spillage

and clean up time.

A belt feeder with a hopper reclaiming broken ores will not have the stress put on it that a primary crusher belt feeder will have on it as the material will already be broken and free flowing.

The belt feeder reclaimer has a drag conveyor just like the drag conveyor used in its primary crusher set up.

The belt feeder does not have choker chains to restict flow to the breaker assembly as there is noo breaker assembly in the throat of the feeder.

The feeder will take a way as much material or as little material as is loaded on it as there is nothing restricing flow into the chute of the feeder.

A restrictor plate is installed in most breakers to keep small boulders from riding over the pick assembly/breaker and being dumped on the conveyor belt carrying away the material. this also regulates the flow to the conveyor.

The mechanics of the feeder itself:

Power to operate the conveyor can be supplied by hydraulic motors at the head shaft and tail shaft or through an electric motor driving a "Falk" gear box through a 200H double row roller chain drive.

The units I am most familiar with have 480 volt electrical power powering them.

The new flight chain: the chain is a heavy alloy chain: the newer chains have pins integral with the links to hold the flights/drags in place, the new flights/drags have a weldment on each end to slip over the pins in the chain links to hold them in place.

The older flights had a square weldment that slipped into the chain link that wash perforated and allowed the flight to rest inside the chain link centerline.

The bed of the feeder has guide rails welded to the floor of the bed to keep the flight chain aligned and parallel during operation.

The feeder bed has numerous shoes to hold the flight chain in place and in line linearly with the bed of the feeder.

The feeder chain is tensioned using grease filled cylinders and steel shims to keep it tensioned.

The feeder chain must be fully tensioned to allow proper operation in reverse if needed.

The end of the feeder bed contains the tailshaft, tailshaft flap

rear bearings and grease tensioning cylinders used to tension the flight chain.

The two tailshaft bearings are set in a separate bearing holder for each bearing that they slide in to allow proper adjustment and tensioning.

The tail shaft flap rides on the tailshaft and rests flush in the bed of the feeder and keeps large material from flowing under the feeder by sealing the end of the feeder.

The tail shaft and headshaft have one fixed bearing and one floating beariing each which allows for the shear pin to break if the flight chain becomes jammed saving the feeder from potential damage.

The drive unit for the flight chain/drag chain:

An electric motor and gear box are mounted on a small pedestal which is mounted to a small frame attached to the feeder. The frame is a separate individual component to allow easier building/assembling of the unit underground.

Typically an electric motor drives the feeder conveyor through a "Falk" right angle output drive gearbox connected to the motor with a rubber coupler which is designed to shear if it is jammed and avoid damaging the motor and gearbox.

The gearbox output shaft has a small 200H double row toothed sprocket keyed and attached to it power the 200H double row roller chain which in turn powers the large 200H double row toothed sprocket at the head pulley which turns the flight chain. the driven 200H double row sprocket has holes to install shear pins in the plate mounted to the head shaft.

Numerous holes in the sprocket face allow for easy positioning of the sproket to reinstall a new shear pin in the event of a broken shear pin.

A box to store extra shear pis is welder tot he sie of the chute for convenience of replacing pins when needed.

The 200H double row drive chain is fully guarded per MSHA regulations. the drive chain does not have an oil bath.

Lubrication of the feeder:

The four bearings and tail flap used in the feeder are all connected to an automatic greaser via separate grease hoses which are fed individually and operated by a cam driven off the other end of the head pulley shaft to pump grease through a metering valve bank.

The gear box uses a gear oil in the 90 weight range, it has a dip stick to check the oil level.

The electric motors only require very a small amount of grease annually.

Care must be taken when inspecting the belt feeder daily to insure proper operation of the automatic greaser and the feeder itself.

My apologies to WR Stamler of Millersburg, Kentucky USA if I missed something in my explanation. ■

Advantages Of Using Coal

Are you going around asking "what is solar energy " to everyone that possibly listen to you? Well, you're not alone. Many people don't understand what this is or how cost-effective it is in saving money on monthly bills.

Suggestions are most welcomed. ■

Re: Reclaiming Of Stacked Coal Without Using Any Underground Ho…

Suggestions are most welcomed Advantages of Using Coal

No. Setting fire to coal seams is not new, not safe, not controlable & coal never was, is or will be, green.  It is black, dirty & polluting but we live with that. No amount of propaganda will alter the facts of coal. There was an exercise in the UK NCB days to burn the coal underground etc etc. A recent newsflash proved that the stuff is still active when it showed noxiuos fumes escaping through cracks in the ground.

It is black, dirty & polluting but we live with that. No amount of propaganda will alter the facts of coal. There was an exercise in the UK NCB days to burn the coal underground etc etc. A recent newsflash proved that the stuff is still active when it showed noxiuos fumes escaping through cracks in the ground.

Pretentious expertise in remote subterranean exploits has been well demonstrated in East Java where the hot mud flows which were released by the adventures in geothermal energy have devastated an entire region & nearly cut off the second largest city in Indonesia.  Stay above ground where we can see what you're up to! Oops! Shouldn't have said that, bush fires and all.

Stay above ground where we can see what you're up to! Oops! Shouldn't have said that, bush fires and all. ■

■

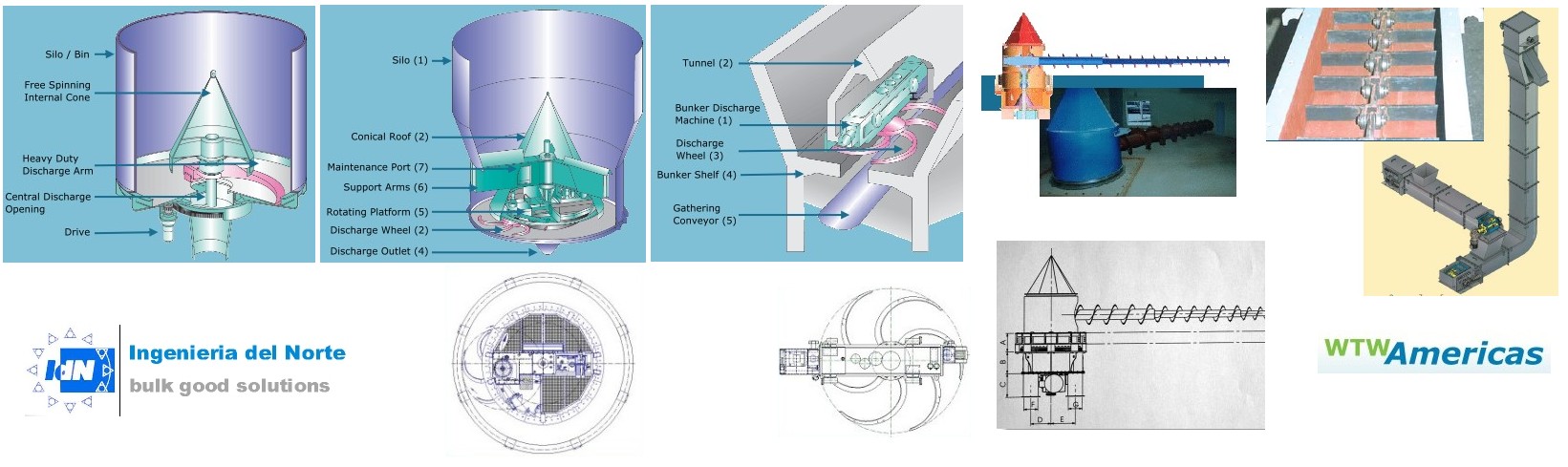

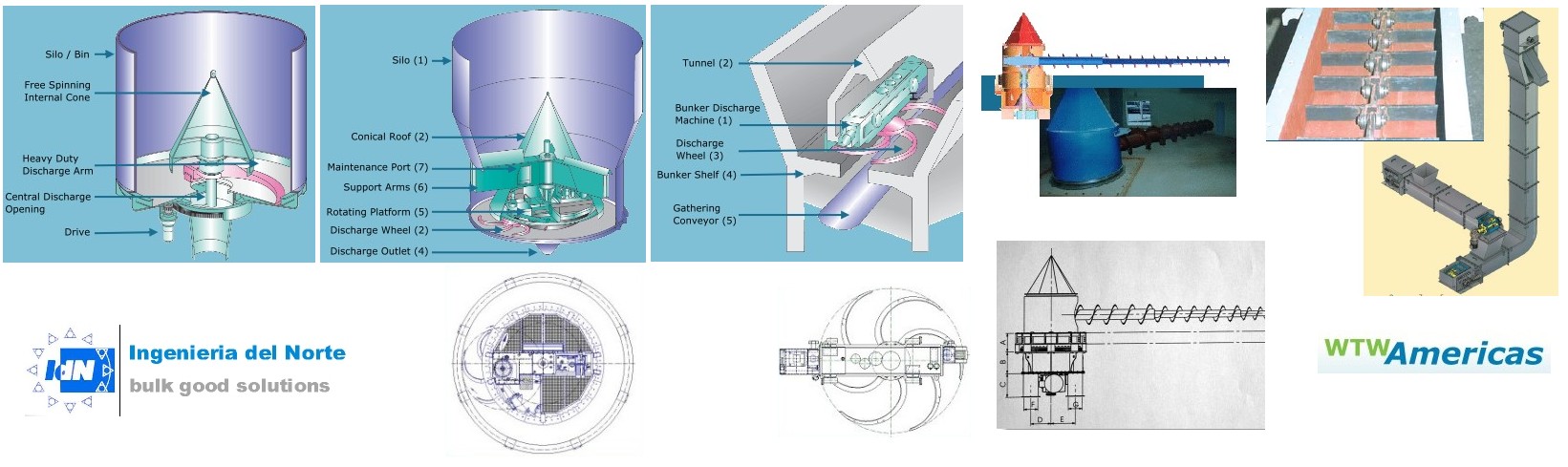

Complementary Feeders

Hello Prashant,

I read you get enough answers, so I will show you briefly complementary feeders with a few pictures

href="http://www.idn-filtracion.com.ar/idn-wtw.feeder.html" target="blank">www.idn-filtracion.com.ar/idn-wtw.feeder.html

I could contact you in case you are not in my area (Latin America)

Regards

dirk tannebaum

href="mailto:bulk.good.solutions.ar@gmail.com">bulk.good.solutions.ar@gmail.com

buenos aires - argentina

Attachments

idn-wtw_tkf-cadena-cajones_aplicaciones (JPG)

■

Reclaiming of stacked coal without using any underground hopper

Hello!

At our thermal plant we're enhancing coal handling facilities for meeting our future needs and we're looking for some low cost, short time construction solutions and While surfing on net for the same I came across this piece of information about feeding of coal without using underground hopper.

"15/11/2004 - The management of the emergency in a coal yard

the best solution is to employ a Stamler/Magaldi Reclaim- feeder as done byEndesa Power Plant from Fiumesanto in Sardinia.

This year Endesa Power Plant, during its full productive period, had the necessity to load the boiler ‘s bunkers but the onlystacker reclaimer available was operating for the coal storage.

The customer needed to:

Transfer over 800 coal t/h from the coal yard to the bunkers

Speed up the coal handling inside the yard (by using the existing means)

Avoid the building of new infrastructures withconsiderable cost and relevant downtime

Keep unalteredthe volume capacity of the coal yard

Magaldi engineers set and carried out a project, the first in Italy, in order to give a solution to the above listed requirement sand, finally, the use of a Reclaim feeder was decided.

The Stamler/MagaldiReclaim-feeder is a compact and sturdy equipment which offers multiple advantages:

Easy installation

It only requires solid and level ground conditions for installation.

Eliminate Costly Civil Work and Site Preparation

The hopperless design allows material to be pushed by dozers or vertically discharged from front-end loaders, trucks, clam shell buckets and excavators directly onto the integral drag conveyor

Efficiency and reliability

Severalreferences worldwide show that the Stamler/Magaldi Reclaim Feeder is custom designed and built to suit heavy, operating, reachingconditions up to 3200 coal t/h capacity. """""

Can some one give me the details of this Stamler/ Magaldi reclaim feeder which uses NO underground hopper for feeding of coal? ■