Dust Suppression In Limestone Quarry

greetings from the eastern US,

First things first, you do not mention whether this dust suppression is required for mobile or stationary use,

here in the USA manufacturers and suppliers of mining machinery

are required to install dust suppression equipment so most of the machinery sold today has dust supression/collection.

If what you are looking for is at the quarry face or for haulage

most people use plain water or foam supressants to control fugitive dust at the crusher station, when regulation of water use is critical, foam supression is your number 1 choice.

If you are using conveyors over long distances water is used at the transfer points to control dust.

In a capsule pipeline systems such as the one sold by pneutrans

limited www.pneutrans.net all the fugitive dust is kept in the capsule pipeline and removed at either the loading or discharge end by the low pressure high volume air that pushes the capsule trains through the system. the idea is to keep things simple so you do not have to worry about it.

If what you are looking for is related to in plant for tertiary

crushing and screening a lot of folks use vacuum systems going to filter banks or it is reintroduced into the product stream.

if you could tell me what you are doing I would gladly give you my advice at no charge. ■

Re: Quarry Dust Suppression

Dust suppression on conveyors may be done installing covers on them. Please, visit www.capotex.com ■

Untitled

we have a great experience in the powder suppression in quarries. The best solution to eliminate the powder is the following one:

In elements, such as mills and sieves, the most effective method is a system of dry fog, while in discharges to storings, the best solution is the one dewed with water.

emcor@emcorsa.com ■

Foam Dc

Hello

Can you plese send me a email of what kind of application you need it for.

Is the problem in the cruchers, tranferpoint ect?

arne.k.ovstebo@tomca.no ■

Re: Quarry Dust Suppression

If you are looking for a reputable vendor, you may contact 1. Fike. or 2. Fenwall. Both of them are experts in dust suppression equipment.

Amrit Agarwal (Tim)

Pneumatic Conveying Consultants

polypcc@aol.com

www.powderandbulk.com/pcc ■

Dust Suppression Systems

I agree with all of folks who replied.

In the limestone quarries i travel into in CANADA.......fugitive dust......around fine screening areas and TERTIARY...high speed VSI crushers is most problematic and common.

Some tips:

A properly installed..........dust enclosure on vibrating equipment helps tremendously to eliminate dust. Going to SLIDER BEDS at transfer positions vs conveyor idler systems......helps a lot.....

If you have a high speed crusher.............that is turning fast...the turbine effect BLOWS...........dust............

TRICK: make sure product conveyor is NOT TO TIGHT OR CLOSE to underside of crusher.......say min 30-36" below turning table. Make sure you install conveyor HOODS.......for at least...15-20 feet after point where crusher product drops onto the takeaway conveyor. THIS ALLOWS airborn dust...........to settle down.....before proceeding to stockpile.

IF NEEDED........a nice..........FOGGING SYSTEM.....will completely solve your fugutive dust problem and suppress dust........and most importantly....NOT CREATE a huge MUDDY MESS all over the place............this is very important factor.

GEORGE BAKER.............CANADA ■

Re: Quarry Dust Suppression

Dear Sirs,

we are a manufacturer of Dust suppression systems.

Please have a look to our website:

www.vsr-industrietechnik.de

or contact me directly

schlabach@vsr-industrietechnik.de

VSR Industrietechnik GmbH

Am Alten Schacht 6

47198 Duisburg

02066-996640

0172-2571022

Thanks in advance ■

Re: Quarry Dust Suppression

Dear sir,

you could consider an enclosed belt conveyor loke the EBS Conveyor.

It has 98% less dust than a conventional belt. It can also negotiate horizontal and vertikal bends.

Capacities up to about 500 ton/hour.

best regards

Frans van der Zee

Enclosed Bulk Systems bv ■

Re: Quarry Dust Suppression

Sir

We are manufacturers of Dust suppression systems and have executed various projects in mines, steel and cement plants all over the world.

regards

saju mathew ■

Re: Quarry Dust Suppression

Hello to you,

please have a look to our homepage

www.vsr-industrietechnik.de

We have the right technology for you.

Contact.schlabach@vsr-industrietechnik.de ■

Hose Reeler

Dear Sir,

Try www.cavotec.com and www.wampfler.com for automated hose reelers

Rashid Motala ■

Re: Quarry Dust Suppression

If your stone is typical of the region then it is very soft and the situation is one of dust collection more than supression. Quite a lot of product is lost as dust & working conditions are appalling. In Ras al Khaimah the conveyor below a tertiary crusher was permanently awash with dust piles & dust generation was so severe that a containment canopy regularly filled to waist level. Housekeeping requirements really interfered with production capacity.

On that sort of product dust control systems are ineffective & a full pneumatic conveying system would be necessary to move the dust to a silo.

If you are handling gabro then please disregard the above.

An earlier reply mentioned dropping the take out conveyor lower than usual for a tertiary crusher : an excellent idea. ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Re: Quarry Dust Suppression

Please contact F. Harley & Co. Pvt. Ltd.

mktsupport@harleygrp.com

F. Harley has many dust suppression system installation reference for limestone applications.

S. Chandra ■

Re: Quarry Dust Suppression

Dear Sirs,

we are a leading company for components for bulk technology.

One of our special products is dust suppression system by

water/air or water.

Please have a look to www.vsr-industrietechnik.de

or give me a direct note to

schlabach@vsr-industrietechnik.de

VSR Industrietechnik GmbH

Am Alten Schacht 6

47198 Duisburg

Phone 0049 2066 996640

Export Manager

W. Schlabach ■

Dust Just Add Water

I recommend a wet based scrubber that will neutralize and isolate the dust problem. The Air Force Inc. wet scrubber systems are designed for just this purpose. Not only do they minimize the amount of water required, but they also quickly immerse the dust in the water and the large CFM ensure that the dust will not collect in the duct system should there be a power failure during the process.

Air Force Inc. has supplied dust suppression systems to many of the mines in Canada and the US. We are actively marketing this globally and know that our solution can benefit those mine applications where water is at a premium and reclamation (gold, platinum and silver) is mandatory. A list of current installations can be provided. These scrubbers have been designed for underground installation as well as quarry installation.

Please contact me if you have any questions! ■

Re: Quarry Dust Suppression

please contact me with details, i am sure we can help.

info@amerya-metal-industries.tk

M-KHALIFA ■

Dust Control

Dear Sir.

We are the sole agent of Controlled Flow Material Transfer System (CFMTS) of US Parramatta Group. Please refer to www.parramattagroup.com. Parramatta's CFMTS is the globally proven solutions to excessive dust, spillage, plugging, downtime, belt wear and combustion dangers. It is an innovation of traditional chute and dust control.

Thank you very much

Looking forward to hearing from you soon.

Sincerely Yours

Ram Liu

Manager of international Business

Jim Way Enterprise Co., Ltd.

Tel: 886-7-8718126

Fax: 886-7-8718128

E-mail: jw@roller.com.tw

Web-site: www.roller.com.tw ■

Dust Suppression Systems

We are producing dust suppression systems for quarries, cement factories, ready mix concrete plants, power stations, waste disposal plants and ship loading since 1994. We are specialized in water systems and it is totally chemical free.

We have installed around 300 systems in Turkey and 35 in 25 countries.

Our systems provide up to 95 % dust suppression. The system uses water and compressed air. The system does not wet the materials as it uses only 1-2 liters of water per one ton of material and no adherence occurs.

We would be very glad to discuss business opportunities with your company.

You can visit our web site for detailed information.

http://www.enveks.com.tr/indexen.asp

Erol Tuna

Export Manager

Env-Ex GULF

United Arab Emirates

etuna@enveks.com.tr ■

Dust Suppression

Dear Sir,

We have pleasure to inform you that we are manufacturing speciality chemicals for various industrial applications. We have Dust Suppression products range 'DUSTRON' for the DUST SUPPRESSION in mining operation for haulage road in open cast mines and for the bulk material handling systems.

We have a Memorandum of understanding (MOU) with Central Mining Research Institute (CMRI) Dhanbad, India which is a part of Council of Scientific & Industrial Research Govt. of India. CMRI is the world recognised Institute for the research in the field of mining operation.

The following products are approved and accepted by the Indian Mining Industries since last 10 years for better environmental and mining conditions.

1. DUSTRON PC Compound: For the open cast mines haul road where the dust emission is because of HEAVY EARTH MOVERS of high capacity trucks Dozzer, Tippler etc. DUSTRON PC is used for various class of mines in India for dust suppression in the mines as under.

(1) Iron Ore Mines

(2) Zinc Mines

(3) Lime Stone Mines

(4) Copper/Chromite Mines

2.DUSTRON PC COAL : For the open cast mines haul road of collieries, railway sidings and coal jetty's road of the ports.

3.DUSTRON PC LIGNITE : For the haulage roads of lignite open cast mines.

4.DUSTRON XT : This product is used for the dust suppression of bulk material handling system where at the transfer point crusher house, dumper platform dust emission is heavy, so along with water spray DUSTRON XT is used to control dust emission.

5.DUSTRON XT COAL : For bulk material handling system of conveyors, dumper platform, wagon tipplers of open cast/ under ground mines, Thermal power plants and coal jetty on the port trust.

All the above products are used in Indian mining industries to control dust for better environment & working conditions which produce no. of advantages.

We hope that you might be consuming some product for similar application. "Using DUSTRON RANGE OF PRODUCT SAVINGS IN WATER is 40%" with other benefits.

If you find any interest we shall send you the detail literature for your reference along with quotation.

We request you to send us your e-mail address to contact you on net.

E-mail: nrd@juno.com

We ensure you to provide you best services and technical back-up to your mines for dust suppression applications.

Awaiting for your valued inquiry.

Thanking you,

Yours faithfully

For N R D Industries

DIPALI SHAH ■

Re: Quarry Dust Suppression

If it is fugitive dust that you wish to control then a dust suppressant is always best. Due to new regulations that you may be aware of now you must or soon will be regulated into using only 100% certified dust control products. The one with the best cost to value ratio that is used in many operations such as yours around the world is Dust Stop. More information may be found by accessing the web site at www.cypherltd.com under Dust Stop which is a product used by some of the largest businesses in the world in your field. Good luck with your problem but this is by far the most effective solution.

Regards,

Norm ■

Dust Suppression Industry

Sir

We are manufacturers of Dust suppression industry and have executed various projects in mines, steel and cement plants all over the world.

regards

Mrs. Dipali Shah-Pandya

N R D Industries

86 Commonweallth Ave

Piscataway, NJ 08854

USA

http;//www.nrdindustrie.com ■

Re: Quarry Dust Suppression

It is nearly 4 years since this thread started. Replies have been reiterated without reading the original question or acknowledging the location mentioned therein. Surely it is time to archive/move this thread to save forum members time to sift through repetitive sales pitches. ■

Dust Control

If you are dealing with Dust control on your roads and other areas Let me introduce you to our product.

HR-TS™ (HAUL ROADS with TOP-SEAL) is a Dust Pollution Control Program from Soils Control International that uses higher concentrations of Top-Seal Liquid Soil Sealant and Stabilizer to control dust pollution on haul roads or any other area with extremely heavy traffic, such as truck parking lots and staging areas. The HR-TS™ Program uses Top-Seal® as a powerful, environmentally safe, liquid soil binder that permanently attaches itself to dust particles and tightly binds them together so that they will be heavy and rendered incapable of becoming airborne. Simply diluted with water in a water truck, Top-Seal is evenly distributed into the soil. A curing process will irreversibly transform a mixture of Top-Seal, dust, and aggregate into a permanently hardened membrane. Occasional maintenance applications, as needed, will control dust pollution on a permanent basis. ■

Dust Control

My company deals in dust control in the Uk and deal in varios different types of systems, my email is odourdust@aol.com if you wish more info.

We can supply standard misting and fogging systems, rotary atomisers and we can offer out biodegradable foam to eliminate dust at source rather than control it once it has become airborne ■

Wlp - Dust Suppression Systems

Dear Sirs,

we are an italian manufacturer of Dust suppression systems and we have executed various projects in mines, steel and cement plants. Our system is based on spraing water trough the air with a new system that saving a lot of energy power and that will completely solve your dust problem.

Please take a look to our website:

www.wlpdust.com

or contact us if you have any questions!

sales@wlpdust.com

Thanks in advance ■

Re: Quarry Dust Suppression

Dust Solutions, Inc. has Dry Fog ultra-sonic water/air driven systems that can be engineered for most mining, quarry, wood-chip and other applications.

We primarily obtain our business from Engineering company referrals, but we also have our own staff of engineers for stand-alone projects.

Please feel free to call or email.

An overview may be all that is necessary to start the discussion, but of course we can utilize pictures, PDF, & CAD files to evaluate and discuss your application, and of course provide a bid.

Thank you,

Stephen ■

Re: Quarry Dust Suppression

We carry out dust suppression in the UK for all industries if we can assist you please email me on odourdust@aol.com ■

Env-Ex Dust Suppression Co. Ltd.

Dear Sir,

We are producing dust control and suppression systems for quarries, cement factories, ready mix concrete plants, power stations, waste disposal plants for ten years. We provide better environment, improved product quality, minimal risk of dust emission, reduced maintenance and clean-up costs, improved employee working conditions and safety to our customers.

We are providing two main systems at the moment, one is "Water and Air" system and the other one is "EcoSpray" system.

"Water and Air" system uses totally chemical free, pressurized water and compressed air together to spray water through predefined nozzles for crushing and screening operations and provide up to 95 % dust suppression depending on crushed material also type of the plant. The system does not wet the materials as it uses only 1-2 liters of water per one ton of material and no adherence occurs.

Our other solution "EcoSpray" system uses the same principles with our “Water and Air” system but with the new designed nozzles which have different dimensioned water spraying technology and new designed control panel which includes a programmable “Siemens LOGO! Series” PLC module provide us airless spraying capability.

So, we do not need air any more and eliminated the need of air compressor. Therefore, we are using only totally chemical free water to suppress dust with this system that we recommend.

It is Economical because you don’t pay for compressor, electricity, spare parts, etc.

It is Ecological because you use minimum energy and no compressor oil, filters, etc.

That is why we have named it as “EcoSpray”.

You pay up to 40% less for having a water spraying system in your crusher and up to 90% less for operating it and get 95% dust suppression depending on crushed material also type of your plant.

The types of EcoSpray system depending on usage are;

1) Low Pressured: 5 - 10 bars water pressure it provides for jaw, rod base, impact, vsi and cone crushers, screeners and pilling points.

2) High Pressured: 100 - 300 bars water pressure it provides for truck dumping points (hoppers) and bigger areas where needs more pressure.

Also, it has two different operation mode options:

1) Manual (Default): We are giving a wired remote control to operator for controlling the lines of nozzle groups he wants. (For example; he can activate or deactivate a line which goes to impact crusher, another line which goes to jaw crusher, screener, etc. Activate/deactivate lines one by one or all at same time.)

2) Automatic: We are putting an automation controller to your crusher's control panels and with the programmability advantages of the powerful PLC module that we use; it is automatically activating the lines to spray water when material came. We are also giving a wired remote control on this option to switch to manual mode and control as manual mode as needed.

I am proud to tell you that our products have CE certification, ISO 9001:2000. Although, I’d like to announce that our systems have been approved by the Turkish Ministry of Environment due to performance and high dust reduction rate achievement in the facilities where the system was installed.

We made around 300 installations in Turkey on medium or small sized local crusher plants owned by various municipalities and some private companies and many local and multinational cement factories (LA FARGE, VICAT and ITALICEMENT). We exported around 50 systems to more than 20 countries including UAE, Oman, Greece, Azerbaijan, Kazakhstan, Morocco, Croatia, Iraq, Libya, Serbia, Sudan, Algeria and Turkish Republic of Northern Cyprus...

We are able to prepare proposals without visiting your or your customer’s plant, if some details are provided.

Details are;

1) The layout of the plant

2) Capacity of crushers (Primary + Secondary)

3) Material crushed in plant

4) Pictures, dimensions and numbers of crushers, screening / belt conveying / stacking points (points where dust is emerged)

5) Which operation mode option you want? (Automatic or Manual)

6) Other details you or your customer wants to share with us.

*********

We are also able to provide Dust Holder Systems to our customers.

Those will be provided;

* Reserve Air-Filters

* Back House System

* Cartridge Filters

* Pocket Filters

* Jet-Puls Type Filters

* Siklons

(We are about to release detailed information and presentations for these products.)

You can find our catalog which describes principles of the system and presents "Water and Air” system at http://www.enveks.com.tr/docs

Please feel free to check our web site at http://www.enveks.com.tr/indexen.asp and do not hessitate to contact me for any questions and further information.

Best Regards,

Gorkem Ogut

Geological Engineer

International Sales Manager

ENV-EX Dust Suppression Co. Ltd.

TURKEY

E-mail: gogut@enveks.com.tr

Mob: 0090 555 997 21 03 ■

Dust Suppression

Please contact with e-mail address, we have vast experience in Dust Suppression Contact:

Mrs. Dipali Shah-Pandya

N R D Industries

86 Commonweallth Ave

Piscataway, NJ 08854.

USA

E-mail : nrdindusties@gmail.com, nrd@juno.com

http://www.nrdindustries.com

You may visit http://www.nrdindustries.com to obtain this information ■

Dust Collection

We manufacture a dust collection system that goes on mobile rock drills. Our product is on all Ingersol Rand rock Drills. The system goes from the collector , cyclone seperator to the pickup pots. Our system can also be modified for many applications where dust collection is required.

www.qmpcorp.com

www.stockmfg.com ■

Dust Suppression

This application sounds like a very good fit for the portable hi-performance dust suppression equipment from Dust Control Technology. You can find info at www.dustboss.com. These machines are in use in many quarrying and mining applications around the world. See: http://www.dustboss.com/index.cfm?pageID=266 and http://www.dustboss.com/index.cfm?pageID=310 for examples of the units in action. ■

Crusher Dust Suppression

I represent company called Dynaset. We make different kind of hydraulic equipments to mobile machinery.

For mobile crushers, we have made many high pressure water dust suppression systems. The water consumption is considerably less than traditional low pressure systems. With 10 nozzles water consumption can be less than 10 l/min, Snow cannon type uses easily 50-150 l/min! We have faced facts that water pressure should be at least 100 bars to develop right size drops for most efficient dust suppression.

Dust suppression nozzles should be pointed directly to dusting material to kill the dust efficiently.

Price of these kind of systems is really reasonable and it's reliable when used right components. Hydraulically powered high pressure water pump is easy to attach almost every mobile working machine and it takes only really small space.

www.dynaset.com

Attachments

high pressure dust suppression_application (PDF)

■

Dust Suppression Industry.

Dear Sir,

Please allow us to introduce ourselves, we are NRD Industries. We are currently offering product such as DUSTRON® range of products for the dust suppression industry. Below is a brief description of product, and also enclosed is more literature for the same.

DUSTRON® :

We also have the pleasure to inform you that we are manufacturing specialty chemicals for various industrial applications. We have Dust Suppression products range 'DUSTRON®' for the dust suppression in mining operation for haulage road in open cast mines and for the bulk material handling systems.

We have a Memorandum of Understanding (MOU) with Central Mining Research Institute (CMRI) Dhanbad, India which is a part of Council of Scientific & Industrial Research Govt. of India. CMRI is the world recognized institute for the research in the field of mining operation.

The following products are approved and accepted by the Indian Mining Industries since last 10 years for better environmental and mining conditions.

1. DUSTRON PC Compound: For the open cast mines haul road where the dust emission is because of heavy earth movers of high capacity trucks Dozzer, Tippler etc. DUSTRON PC is used for various classes of mines in India for dust suppression in the mines as below.

(1) Iron Ore Mines

(2) Zinc Mines

(3) Lime Stone Mines

(4) Copper/Chromite Mines

2. DUSTRON PC COAL: For the open cast mines haul road of collieries, railway sidings and coal jetty's road of the ports.

3. DUSTRON PC LIGNITE: For the haulage roads of lignite open cast mines.

4. DUSTRON XT: This product is used for the dust suppression of bulk material handling system where at the transfer point crusher house, dumper platform dust emission is heavy, so along with water spray DUSTRON XT is used to control dust emission.

5. DUSTRON XT COAL: For bulk material handling system of conveyors, dumper platform, wagon tipplers of open cast/ under ground mines, Thermal power plants and coal jetty on the port trust.

All the above products are used in Indian mining industries to control dust for better environment & working conditions which produce a number of advantages.

We hope that you might be consuming a product for similar application. It will be helpful to know that "Using DUSTRON range of products equals to a savings of water by 40%" with other benefits.

We ensure you to provide the best services and technical back-up to your mines for dust suppression applications. Please contact us at nrdindustries@gmail.com for more information regarding the information mentioned above or enclosed within. Thanking you in advance for your time and hoping to hear from you soon.

Sincerely,

Mrs. Dipali Shah-Pandya

N R D Industries

86 Commonwealth Ave

Piscataway, NJ 08854.

USA

E-mail : nrdindusties@gmail.com, nrd@juno.com

http://www.nrdindustries.com

You may visit http://www.nrdindustries.com to obtain this information

http://www.nrdindustries.com/dustron...esentation.exe ■

Dust Suppression

Dear Sir,

Please contact with e-mail address, we have vast experience in Dust Suppression

Contact:

Mrs. Dipali Shah-Pandya

N R D Industries

86 Commonweallth Ave

Piscataway, NJ 08854.

USA

E-mail : nrdindusties@gmail.com, nrd@juno.com

http://www.nrdindustries.com

You may visit http://www.nrdindustries.com to obtain this information ■

Quarry Dust Control

Take a look at www.dustboss.com. This equipment is very effective on large-scale outdoor operations, able to cover ~80,000 sq ft with a single oscillating machine. ■

Large Scale Dust Control

You may be interested in the latest publication by the British Materials Handling Board: -

"Control of Dust in Large Scale Bulk Solids Handling" available in electronic form @ £ 20.00 or hard copy, (142 A4 pages,) @ £50.00 plus £8.00 p & p. contact lynflow@btinternet.com.

Lyn Bates ■

Re: Quarry Dust Suppression

Dear Sir,

we have years of specific dust suppression experience in large quarries exposed winds and air currents. We supply some of the largest multinational customers world wide, and are also governmental advisors on the topic. Please view

href="http://www.comacenvironment.com" target="blank">www.comacenvironment.com . We also have a large number of case studies available.

Attachments

nuova immagine (7)JPEG:forum_attachments/file_container/nuova immagine (7).jpg (BMP)

nuova immagine (10)JPEG:forum_attachments/file_container/nuova immagine (10).jpg (BMP)

nuova immagine (14)JPEG:forum_attachments/file_container/nuova immagine (14).jpg (BMP)

■

Dustron™ Range Of Products For The Dust Suppression Industry

Dust suppression and odour abatement in medium sized areas

A-JET35

A range of versatile dust suppression and odour control machines engineered to launch at a maximum distance of 35 meters ideal conditions. The machines are easy to use and entirely programmable (S series only).

The maximum area covered is 3077 m with 3 kW.

The range also includes autonomus mobile machines on trailer, or crawler mounted, with electric generators, water pumps and water tanks.

All machine components are enclosed in a heated body (option), and are able to operatare at extreme temperatures.

Dust suppression and odour abatement in large sized areas

A-JET65

A powerful series of compact machines able to cover areas up to 13266 m, with 65 meters jet distance, powered by 11,5 kW motor fan.

These models are entirely programmable (S series only).

The series is also manufactured in autonomous units on trailer or crawler, with electric generators, water pumps and water tanks, easily manouvrable on site.

All components are enclosed in a heated body (option), to enable the machines to operate at extreme temperatures.

Very large areas

A-JET75

A new series of Dust Suppression fog cannons currently under testing.

The models, completely hydraulic, will be able to cover areas up to 17.600 square meters.

Dear Sir,

Please allow us to introduce ourselves, we are N R D Industries. We are currently offering product such as DUSTRON™ range of products for the dust suppression industry. Below is a brief description of product, and also enclosed is more literature for the same.

DUSTRON™ :

We also have the pleasure to inform you that we are manufacturing specialty chemicals for various industrial applications. We have Dust Suppression products range 'DUSTRON™' for the dust suppression in mining operation for haulage road in open cast mines and for the bulk material handling systems.

We have a Memorandum of Understanding (MOU) with Central Mining Research Institute (CMRI) Dhanbad, India which is a part of Council of Scientific & Industrial Research Govt. of India. CMRI is the world recognized institute for the research in the field of mining operation.

The following products are approved and accepted by the Indian Mining Industries since last 10 years for better environmental and mining conditions.

1. DUSTRON™ PC Compound: For the open cast mines haul road where the dust emission is because of heavy earth movers of high capacity trucks Dozzer, Tippler etc.

DUSTRON™ PC is used for various classes of mines in India for dust suppression in the mines as below.

(1) Iron Ore Mines

(2) Zinc Mines

(3) Lime Stone Mines

(4) Copper/Chromite Mines

2. DUSTRON™ PC COAL: For the open cast mines haul road of collieries, railway sidings and coal jetty's road of the ports.

3. DUSTRON™ PC LIGNITE: For the haulage roads of lignite open cast mines.

4. DUSTRON XT™: This product is used for the dust suppression of bulk material handling system where at the transfer point crusher house, dumper platform dust emission is heavy, so along with water spray DUSTRON XT is used to control dust emission.

5. DUSTRON XT™ COAL: For bulk material handling system of conveyors, dumper platform, wagon tipplers of open cast/ under ground mines, Thermal power plants and coal jetty on the port trust.

All the above products are used in Indian mining industries to control dust for better environment & working conditions which produce a number of advantages.

We hope that you might be consuming a product for similar application. It will be helpful to know that "Using DUSTRON™ range of products equals to a savings of water by 40%" with other benefits.

As per the basic cost it looks higher side but actually its too lower in comparison of USA based products.

We want to highlight the specific properties of our dust suppressant chemical DUSTRON PC.

The special character of this product is that :

1. Penentrate in the soil & other products are availabe are carpeting over the soil.

2.Agglomerated the whole surface & indide soil but other product only work as carpet over the soil

3.Do not scrathed out with Heavy Heart Moving Machineries/tyres but other product are scratched out.

4. Stable above 45 degree centrigrade

So please go with the technical application system.

For your kind reference we are submitting the Techno – commercial product in pdf formate., which are on the basis of following data:

1. Mixing Ratio : 1: 2500

2. Chemical required per Square Meter per day := 0.0002 Kg

3. Chemical required per Square Meter per application year (300 days) := 0.062 Kg

4. Cost of Chemical per Square Meter per day = $0.0023

5. Cost of Chemical per Square Meter per day = $0.6842

We are very serious regarding our business development & we are manufacturing highly concentrated products. So please also send the name of other products with application details. So that we technically as well as commercially prove how our product are best.

We hope that you might be consuming a product for similar application. It will be helpful to know that "Using DUSTRON™ range of products equals to a savings of water by 40%" with other benefits.

We ensure you to provide the best services and technical back-up to your mines for dust suppression applications. Please contact us at nrdindustries@gmail.com for more information regarding the information mentioned above or enclosed within. Thanking you in advance for your time and hoping to hear from you soon.

Sincerely,

Mrs. Dipali Shah-Pandya

N R D Industries

14 Whittlesey Avenue

West Orange, NJ 07052.

USA

E-mail : nrdindusties@gmail.com, nrd@juno.com

http://www.nrdindustries.com

http://www.nrdindustries.com/dustron...esentation.exe

http://www.youtube.com/user/nrdindustries

Title: DUSTRON™ Range of Products

Description: DUSTRON™ Range of Products

http://www.powderandbulk.com/videos/...46c9df0da541a8 ■

Re: Quarry Dust Suppression

We have installed around 300 systems in Turkey and 35 in 25 countries.

Our systems provide up to 95 % dust suppression. The system uses water and compressed air. The system does not wet the materials as it uses only 1-2 liters of water per one ton of material and no adherence occurs.

We would be very glad to discuss business opportunities with your company.

You can visit our web site for detailed information.

http://www.enveks.com.tr/indexen.asp

Erol Tuna

Export Manager

Env-Ex GULF

United Arab Emirates

etuna@enveks.com.tr

Dear Erol Tuna,

We appreciate that you took time from your busy day to take attention to this message, please view this mail in .Please allow us to introduce ourselves, we are N R D Industries. We are the distributor of KALMATRON®, a SUPER CONCRETE ADDITIVE that we believe has no equal in the United States or world-wide. Below is a brief description of products, and also enclosed is more literature for the same.

Kalmatron® Corporation has been established by the owners of patents, technologies, and trademark of Kalmatron® products. Kalmatron® Corporation is the manufacturer and supplier of its products for the building industry on the world market by appointed agencies and companies.

The Kalmatron® concept was discovered by Dr. Alex V. Rusinoff in 1982. First production began in 1992. The Kalmatron® theory created different mechanisms of cement grain decay, which gives numerous technologies for repair and building of new structures with highest performance of durability.

Products Trade Name Description

Admixtures & Coatings

Admixture KF-A KALMATRON® KF-A

KALMATRON® KF-A is the first of the generation of chemically active admixtures to the cement containing mixes that increases cementiiotus value and volume of cement grain. Therefore, the lower quality cement has the higher the effectiveness of KF-A. That is why the results of applications are varying but always exceeding targeted one.

Coating KF-B KALMATRON® KF-B

KALMATRON® KF-B works as a remedial coating on old, aged, or deteriorated concrete and masonry structures in a damp environments.

KALMATRON® KF-B is the only known product that works in severe sewage, acid, and petroleum rich environments as a continuous coating. Preparation on the job site only involves mixing KF-B powder with water in a volume to volume ratio of 3 to 1.

Hardened Plugs KF-C KALMATRON® KF-C

KALMATRON® KF-C is the fastest hardening plug compound for stopping pressured leaks in concrete, wooden, and masonry structures. KF-C plugs leaks with pressures up to 19 Bar. It is applicable in underwater conditions with the use of hardened KF-C plugs or a compressor for pressure strewing KF-C powder.

Admixture KF-D KALMATRON® KF-D

Light gray powder with specific smell. After application, the smell disappears. This inorganic compound works as an admixture to cement containing Earth-Materials-Sealants (EMS).

Improves density and impermeability of soil or severely deteriorated structures. KF-D added to standard EMS mixes can be used for injections under or into sinkholes, foundations, tunnels, dams, wet and polluted soils, etc.

Coating KF-ECOAT KALMATRON® KF-ECOAT

ADVANTAGES OF COATING KF-ECOAT

Simplest surface preparation---just wet the surface with water.

Applicable under low temperature on site.

No specific qualification of staff is required.

No costly removal and replacement of the deteriorated structure-just restore it.

Impermeability to wall seepage is 100%.

Hardner - KF-EHARD KALMATRON® KF-EHARD

ADVANTAGES OF HARDENER KF-EHARD

Non-Rusting - Stain-Resistant

Permanent color - non-fading

Curing effect of fresh concrete surface is provided.

Various types of finishes and coloring effects

Increases serviceability of concrete floors.

Admixture KF-EADMIX KALMATRON® KF-EADMIX

ADVANTAGES OF ADMIXTURE KF-EADMIX

The water-cement ratio is standard or lower by up to 10%.

The mixing time is standard and the viscosity of the mix is much better.

Slump is higher by up to 20% without additional water.

Shrinkage is lower by up to 35%.

Impermeability of structure is 100%.

Protective Coating -KF-F KALMATRON® KF-F

KALMATRON® KF-F is the strongest protective coating for old and/ or deteriorated concrete and masonry structures. Provides superficial density with highest resistance to chemical and environmental corrosions. KF-F is liquid-impermeable and is the best available coating against abrasion, vapor and liquid transmission, and freeze-thaw cycles. Applicable in dry, hot, cold and damp environments by brush or spray.

Light-gray to ivory colored coarse powder; after being mixed with water, it becomes a light yellow solid.

Liquid Spray KF-G KALMATRON® KF-G

KALMATRON® KF-G is a liquid spray for rehabilitation of degraded concrete rheology. KF-G represents a new concept in concrete rehabilitation technology and became highly popular because of its effective performance and simplicity of application. In most cases, after KF-G is applied to the damaged area there is no need for it to be covered with any additional layer.

Cementitious Coating KF-H KALMATRON® KF-H

KALMATRON® KF-H is a finishing cementitious paint and patching material for protection of wooden structures. The 1.5 mm thick layer of KF-H provides a durable coat with highest resistance to atmospheric and biological damage. KF-H is applicable by brush or trowel in dry and damp environments. Provides rock solid abrasion resistance, liquid impermeability, and freeze-thaw resistance. KF-H waterproofs both the negative and positive sides of dry orsoaked surfaces.

Heat/Cold Isolation Compound KF- I KALMATRON® KF- I

KALMATRON® KF-I is a thermoresistant inorganic, non asbestos compound designed for heat/cold protection of concrete, masonry, and wooden structures. KF-I is impermeable to liquids and attenuates temperature cycles.

KALMATRON® KF-I is applicable for industrial walls and ceilings of metallurgic and chemical industries, food processing and storage facilities, cooling tanks of nuclear plants, fire protection separators, boiled water supply pipes, heating joints, etc.

PreMix KF-JET KALMATRON® KF-JET

KALMATRON® KF-Jet designed as a premix to the dry Ordinary Portland Cement (OPC) powder for production of Rapid Set Cement (RSC) and Fast Setting Cement (FSC) with controlled setting time.

Distinctive difference from known products is that concrete after application has twice lower drying shrinkage cracks, higher compressive strength and adjustable hardening time.

Admixture KF-K KALMATRON® KF-K

KALMATRON® KF-K is an admixture to conventional concrete mixes used to quickly prepare Patching Concrete with high viscosity, strong adhesion and without cracks. KALMATRON® KF-K, added as 10 Lbs/CY or 6 Kg/m3 increases resistance to abrasion and impermeability to any liquids, including purified oil and gasoline. Final Hardening Time (FHT) varies from 45 minutes to 4 hours, which depends on patch size, water amount and/or mixer speed.

Admixture KC KALMATRON® KC

KALMATRON® KC was developed as an admixture to cement to increase hydration by molecular decay of unstable relations between foreign inclusions with cement particles. After that, hydration is an entirely completed reaction with higher performance of concrete rheology that obtained many features of High Performance Cements and High Alumina Cements. The lower the grades of cement powder, the higher the effectiveness of KC.

Admixture KF-SEA KALMATRON® KF-SEA

KALMATRON® KF-SEA is an admixture to regular concrete mixes containing unwashed sea sand and sea gravel where hydration of cement may be provided with sea water as well. Gray powder with specific smell. After application the smell disappears. This inorganic cementitious compound discharges the electrochemical potential of most sea salts, which are aggressive to concrete structures.

Used for enhancing concrete and reinforced concrete in centrally loaded foundations, pillars, walls, columns, etc. Not for bending elements with thickness less than 450 mm. Used for Facilities for Industrial and Military hazardous waste, dams, tunnels, heavy traffic roads, ramps, seaports, airports, etc.

Cementitious Radiation Attenuation KF- KALMATRON® KF-

KALMATRON® KF- is a cementitious powder designed for attenuation of , and radiation. KF- dry density is 2,500 Kg/m3, wet density is 3,500 Kg/m3. KF- deactivates contamination, restores building structures, attenuates radiation and supresses sources of radiation and other radioactive contamination. KF- can be applied as a coating, as an admixture to the concrete mix, or it can be strewn onto or into the source of radiation.

Additive KF-ASH KALMATRON® KF-ASH

KALMATRON® KF-ASH is an additive to concrete mix containing over 50% of fly ash, slag ash or crumbled slag from the weight of cement. In order to utilize incinerated industrial waste (IIW) with maximum benefits, that concrete can be successfully used for conventional structures and is widely recommended for urban infrastructure.

Concrete Masonry Unit (CMU) KALMATRON® BLOCK

Concrete Masonry Units are available in standard demensions with different shapes and volumes of air-enclosed space for use in diverse climates.

Earthquake Protection SEISMIC STAR

Seismic Star is an underground wall designed for dissipation of shear rupture between soil and Seismic Star with reduction of impulse surplus pressure up to 40% and more.

Admixture 100® Admixture 100®

100® is a concrete class upgrading admixture applicable where concrete, grout, or plaster need to be without shrinkage cracks, efflorescence, and post-hardening deformations, water/vapor proof, and stable to ecological and industrial corrosions (<3; salt up to 20%; temperature up to +400° and - 50°).

Unique Applications of KALMATRON®

KALMATRON® products are widely distributed on the world building materials market for the conventional applications and unique projects.

Remedial Layer

SHIELDCRETE The companies "Kalmatron® Corporation", and "Shotcrete Technologies Inc." provide unique shotcrete technologies and materials for cliquid impermeability, superficial density and compressive strength.

Remedial Layer

KALMATRON® PLASTCRETE Highest performance of successfully designed and applied PLASTCRETE classifies it as a protective remedial layer with effectiveness of sophisticated coats and simplicity of stucco application.

It's all about polymers which are never been known for durability and accepted by Int. sanitary foundation. It is a past of civilization.

Thousands of domes are built in the USA made of shotcrete with KF-A by our mix design Plastcrete as attached to this letter (www.shieldcrete.com).

Thousands miles of water carrying pipe lines and aqueducts are repaired by Kalmatron, which saved trillions of dollars to replace them.

We ensure you to provide the best services and technical back-up to your applications. Please contact us at nrdindustries@gmx.com for more information regarding the information mentioned above or enclosed within. Thanking you in advance for your time and hoping to hear from you soon.

Sincerely,

Mr. Dilip Shah

N R D Industries

14 Whittlesey Avenue

West Orange. NJ 07052.

USA

Cell No: 1-848-391-1248

E-mail : nrdindustries@gmx.com, nrdindusties@gmail.com, KalmatronWorld@aol.com

Dr. Alex Rusinoff Tel No: 1 415 385 3290

www.concreterepair.name

www.kalmatron.com

www.shieldcrete.com

www.blockdegree.com

www.seismicstar.com

www.nrdindustries.com ■

Dustron™ Range Of Products For The Dust Suppression Industry

Please allow us to introduce ourselves, we are N R D Industries. We are currently offering product such as DUSTRON™ range of products for the dust suppression industry. Below is a brief description of product, and also enclosed is more literature for the same.

DUSTRON™ :

We also have the pleasure to inform you that we are manufacturing specialty chemicals for various industrial applications. We have Dust Suppression products range 'DUSTRON™' for the dust suppression in mining operation for haulage road in open cast mines and for the bulk material handling systems.

We have a Memorandum of Understanding (MOU) with Central Mining Research Institute (CMRI) Dhanbad, India which is a part of Council of Scientific & Industrial Research Govt. of India. CMRI is the world recognized institute for the research in the field of mining operation.

The following products are approved and accepted by the Indian Mining Industries since last 10 years for better environmental and mining conditions.

1. DUSTRON™ PC Compound: For the open cast mines haul road where the dust emission is because of heavy earth movers of high capacity trucks Dozzer, Tippler etc. DUSTRON™ PC is used for various classes of mines in India for dust suppression in the mines as below.

(1) Iron Ore Mines

(2) Zinc Mines

(3) Lime Stone Mines

(4) Copper/Chromite Mines

for unpaved road Dustron PC range are suitable according to soil conditions. We have an experience that Dustron PC compound is suitable for Lime stone mines of cement industries, metal mines while Dustron PC coal type product is suitable for collieries and lignite mines.

For cement road above class of dust suppression chemicals does give promising results as the road does not have absorbent surface.During the transportation of dumper on cement road because of air blowing the dust is generate which is air born dusting so you have to cover with some material like plastic etc.or spray water with Dustron FM type product.

We have experience that minimum 10 to 15 days trial will give you desirable performance and not with a small sample.

2. DUSTRON™ PC COAL: For the open cast mines haul road of collieries, railway sidings and coal jetty's road of the ports.

3. DUSTRON™ PC LIGNITE: For the haulage roads of lignite open cast mines.

4. DUSTRON XT™: This product is used for the dust suppression of bulk material handling system where at the transfer point crusher house, dumper platform dust emission is heavy, so along with water spray DUSTRON XT is used to control dust emission.

5. DUSTRON XT™ COAL: For bulk material handling system of conveyors, dumper platform, wagon tipplers of open cast/ under ground mines, Thermal power plants and coal jetty on the port trust.

All the above products are used in Indian mining industries to control dust for better environment & working conditions which produce a number of advantages.

We hope that you might be consuming a product for similar application. It will be helpful to know that "Using DUSTRON™ range of products equals to a savings of water by 40%" with other benefits.

As per the basic cost it looks higher side but actually its too lower in comparison of USA based products.

We want to highlight the specific properties of our dust suppressant chemical DUSTRON PC.

The special character of this product is that :

1. Penentrate in the soil & other products are availabe are carpeting over the soil.

2 .Agglomerated the whole surface & indide soil but other product only work as carpet over the soil

3. Do not scrathed out with Heavy Heart Moving Machineries/tyres but other product are scratched out.

4. Stable above 45 degree centrigrade

So please go with the technical application system.

For your kind reference we are submitting the Techno – commercial product in pdf formate., which are on the basis of following data:

1. Mixing Ratio : 1: 2500

2. Chemical required per Square Meter per day := 0.0002 Kg

3. Chemical required per Square Meter per application year (300 days) := 0.062 Kg

4. Cost of Chemical per Square Meter per day = $0.0023

5. Cost of Chemical per Square Meter per day = $0.6842

We are very serious regarding our business development & we are manufacturing highly concentrated products. So please also send the name of other products with application details. So that we technically as well as commercially prove how our product are best.

We hope that you might be consuming a product for similar application. It will be helpful to know that "Using DUSTRON™ range of products equals to a savings of water by 40%" with other benefits.

We ensure you to provide the best services and technical back-up to your mines for dust suppression applications. Please contact us at nrdindustries@gmail.com for more information regarding the information mentioned above or enclosed within.

Thanking you in advance for your time and hoping to hear from you soon.

Sincerely,

Mr. Dilip Shah

N R D Industries

14 Whittlesey Avenue

West Orange, NJ 07052.

USA

E-mail : nrdindustries@gmail.com, nrdindustries@gmx.com, nrd@juno.com

http://www.nrdindustries.com

http://www.nrdindustries.com/dustron...esentation.exe

http://www.youtube.com/user/nrdindustries

Title: DUSTRON™ Range of Products

Description: DUSTRON™ Range of Products

http://www.powderandbulk.com/videos/...446c9df0da541a ■

Dust Suppression System

Dear Sir,

We have read your requirement. We wish to introduce ourselves as one of the leading manufacturer & exporter of Industrial Fans/Blowers & Dust Collectors in India We would like to mention that we are supplying our products to numerous clients for past 3 decades in every possible industrial segment. We are an NSIC Registered firm.

OUR RANGE OF PRODUCTS

I.D./F.D. Fans/Centrifugal Blowers/Trim Blowers/SISW Fans/DIDW Fans.

Axial Flows Fans

Dust-Collector /Bag Filter System/ Multi Clone/ Cyclone separator

Roof Extractor

Man coolers

Air washers/ Air Filtrations/ Scrubbers/Prefilters/ Filters.

Air Curtains/ Rotary air lock systems

Fume Exhaust System.

Turbine Blowers/Roots Blowers/ Rotary Air Lock.

Special purpose fans on design, Reaction Vessels, Agitators, etc

Please visit our Website www.deeptiair.com to know more about our company.

We await your reply.

Warm Regards,

Gautam.R.Dubey

For Deepti Airsystems & Fabricators Pvt.Ltd.

H/P: 91-9867392998

Website: www.deeptiair.com

E-Mail: info@deeptiair.com

■

Re: Quarry Dust Suppression

Hello Sir

We are manufacture of dust removing system/fans/silencers/ventilation system in China.

Our website is www.zdqk.com

my company email: gxl@zdqk.com

my hotmail: ashleelin@live.cn

Any other questions please feel free to contact me.

Ashlee Kuan

MSN: ashleelin@live.cn

Mob: +86 15802658561

Tel: +86 731 82883816 ext: 3211

Fax: +86 731 82883812 ■

Dust Control

I would recommend two recent publications: -

'Guide to the handling of dusty materials in large bulk solids handling', by The British Materials Handling Board 2011,and

'Dust control handbook for induistrial minerals, mining and processing', by The Department of Health and Human Services. R.I. 9689, report of investigation 2012. ■

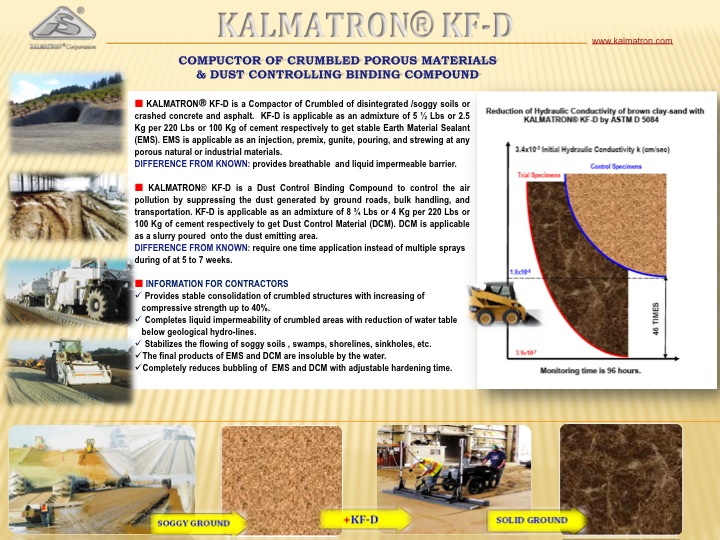

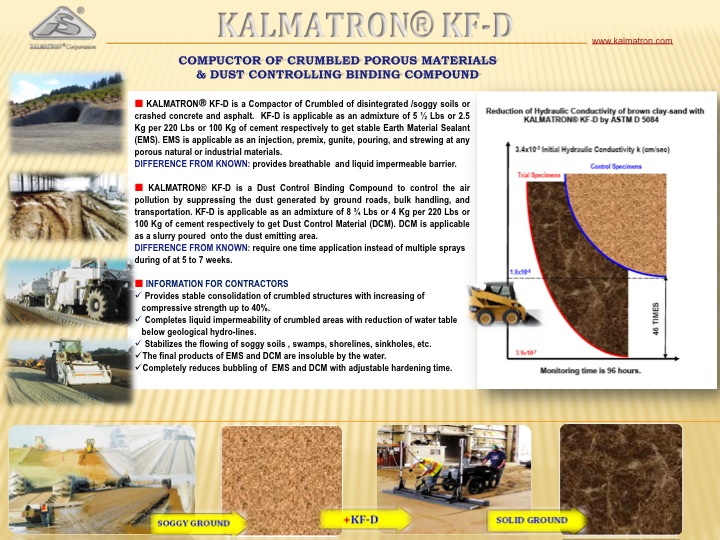

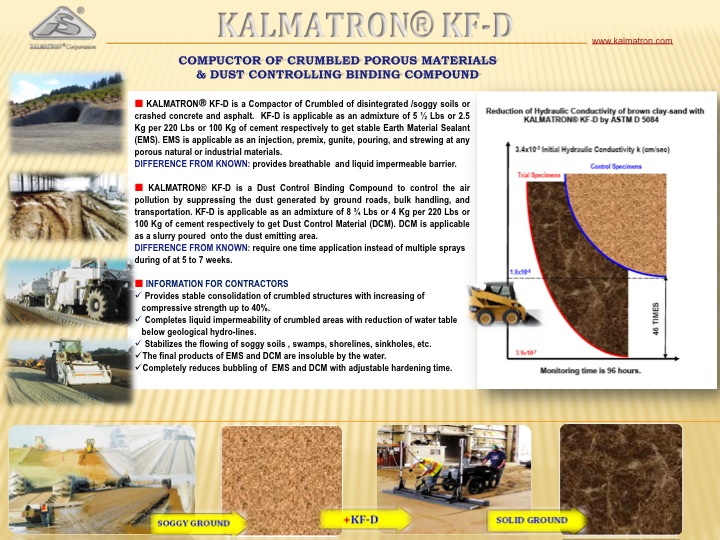

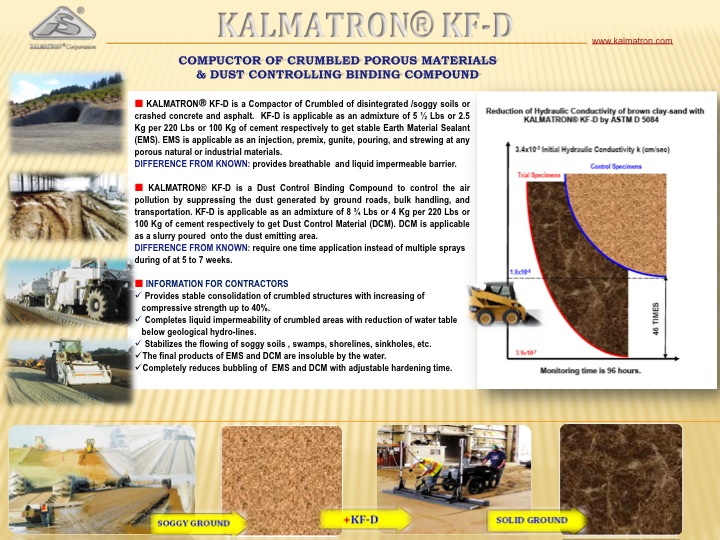

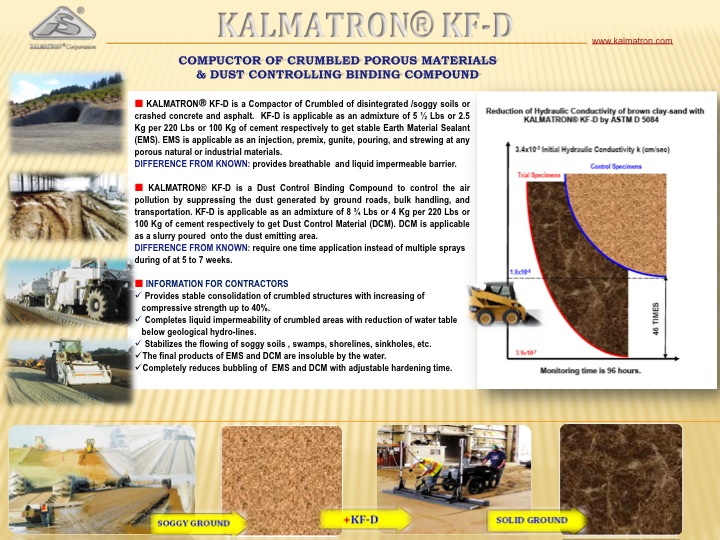

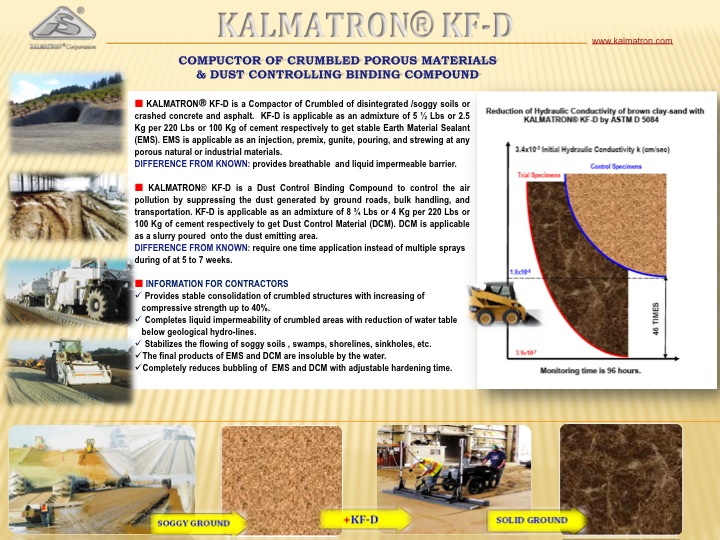

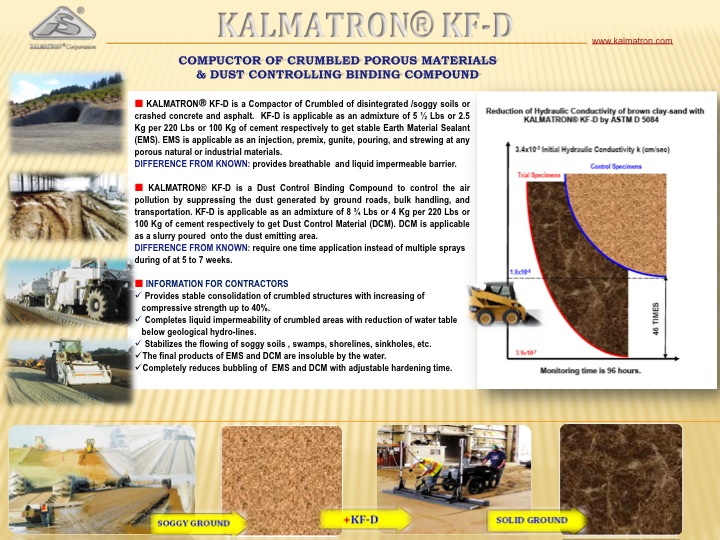

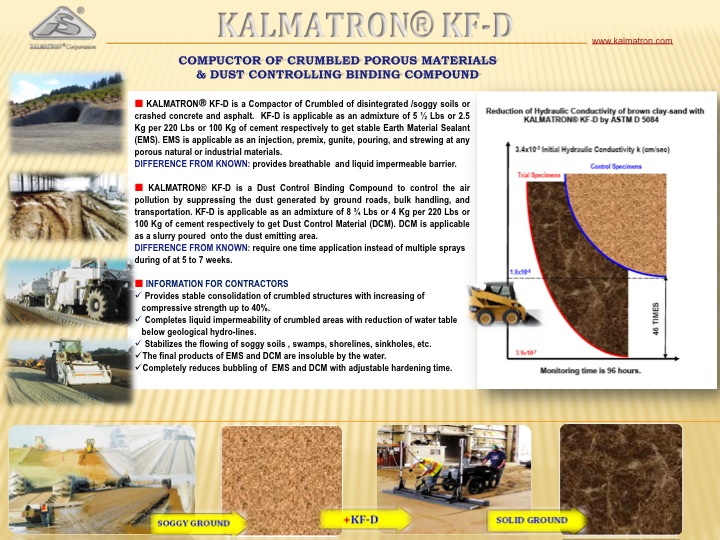

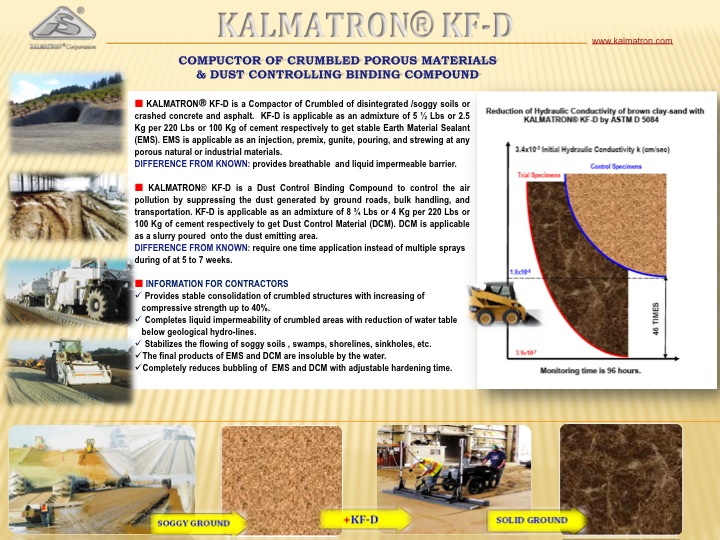

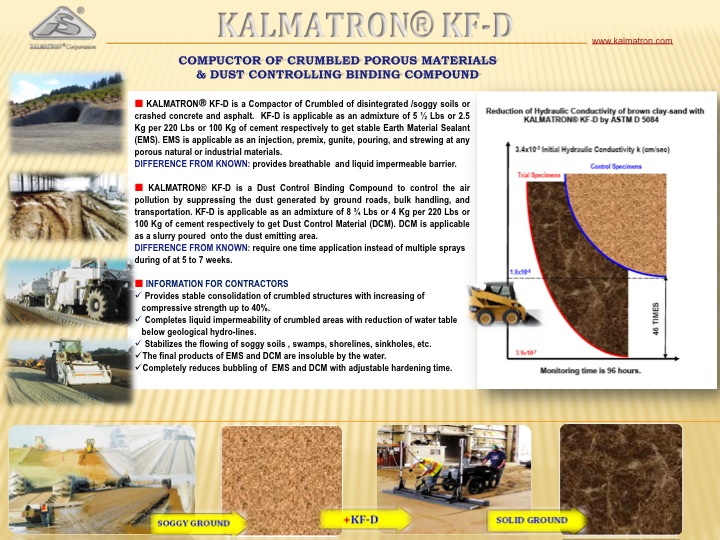

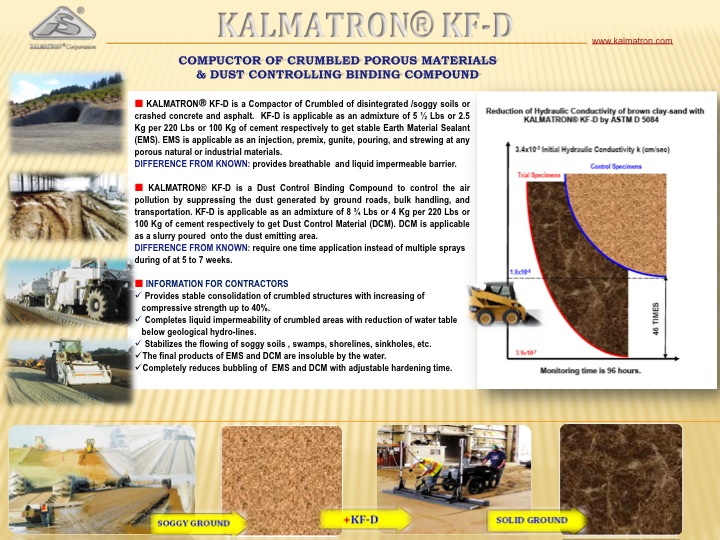

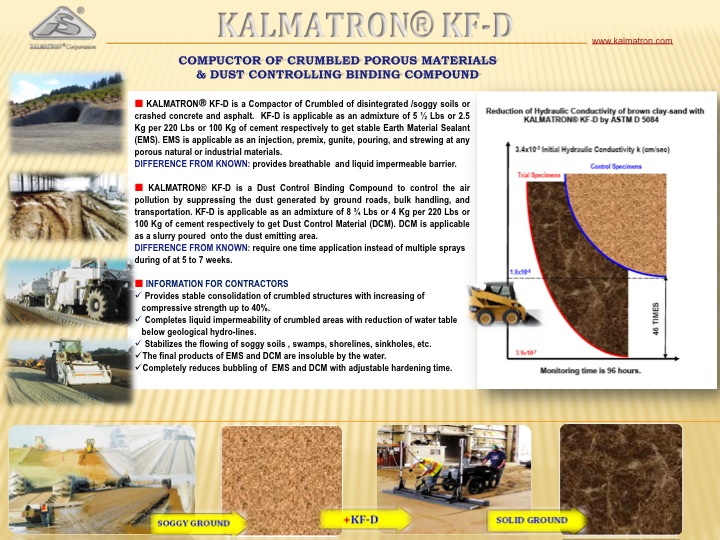

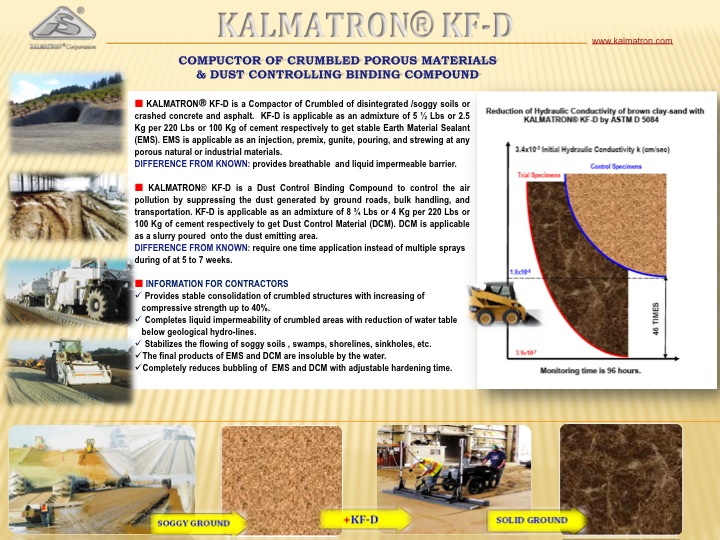

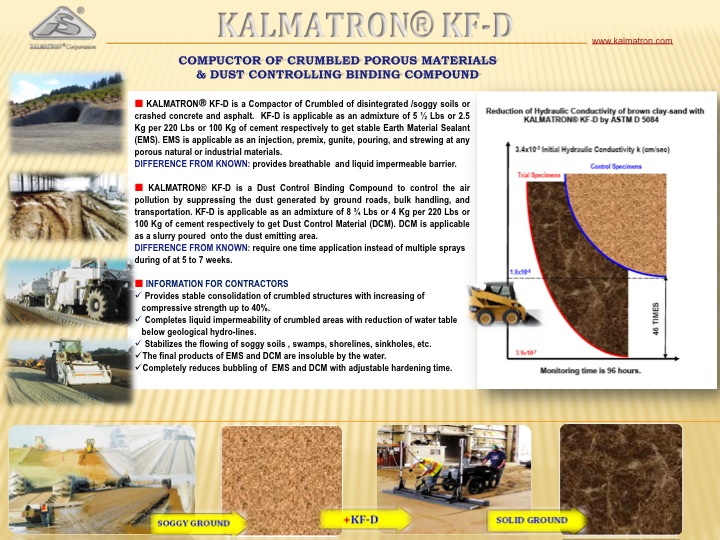

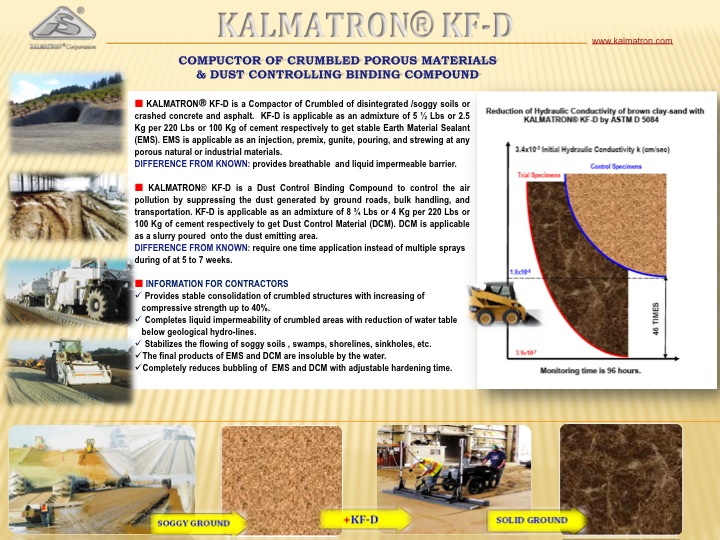

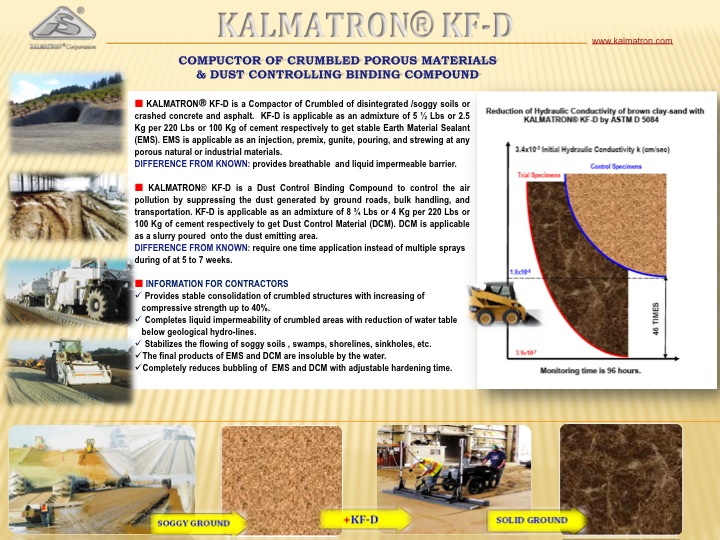

Dust Controlling Binding Compounds As Stadiums, Airports Runway…

href="showthread.php?p=7618#post7618" rel="nofollow">

Please can you respond with your contact info and experience with this application.

Thank you.

Dear Colleagues,

We're working with concretes, grouts and mortars. Dust reduction could be provided by KF-D premixed with the cement and sprayed and rolled down on ground to prevent dust emission.

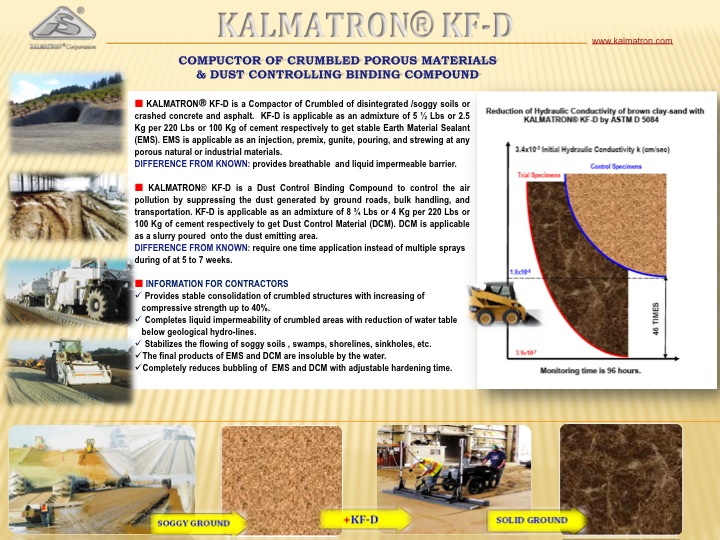

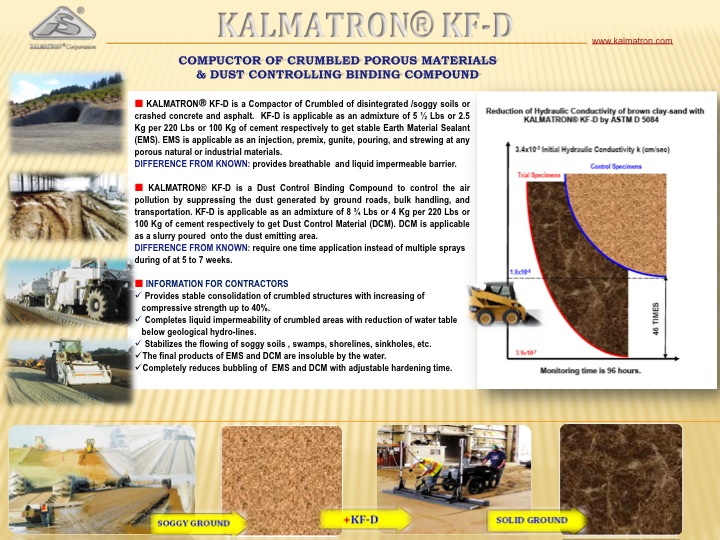

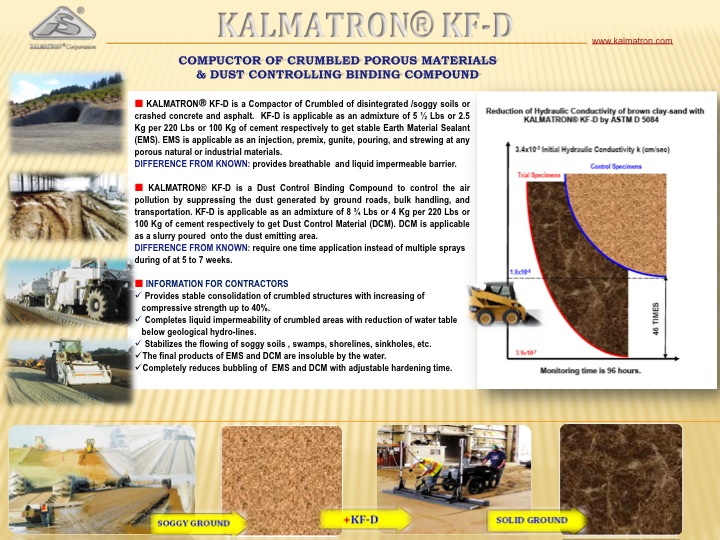

KALMATRON® KF-D designed as an admixture to the Cement’s Soils Containing Sealers of the CMS (Crumbled Material’s Sealant) for enhancement of soils consolidation with strength accelerating and any required level of liquid impermeability.

"Restoration of damped and soggy areas up to the finished objects such as stadiums, auto & rail roads, water canals and ponds, Cement Plants, Thermal power plants, Fertilizers plants, Steel plants Sulfur producer and Ports Jetty such as Hydro Carbon Surfactant, Hydro Carbon Surface Treatment Material, Unpaved Dirt Roads, Road Dust Control, Erosion Control, Road Stabilization, Construction Sites, Fugitive Dust Control,Heavy Haul Roads,Land Development, Silt Loading Control, Construction Parking, Parking Lot Dust Control, Haul Road Dust Control, Parking Lot Solidification, Event Parking Lots, Parking Lot Dust Control, Event Dust Control, Parking Lot Stabilization, Road Shoulders, Shoulder Dust Control, Road Base & Sub-Base, Road Base Stabilization, Sub-Base Stabilization, Mud Suppression, Unpaved Driveways, Driveway Dust Control, FOD Control, Airports runways, Runway Stabilization, Helipads & FARPs, Helipad Dust Control, LZ FOD Control,Pad Stabilization, Airport Taxiways, Airfield Dust Control, Airport FOD Control, Road Reclamation, Milling Stabilization, Forestry Roads,

Recycled Asphalt, Agricultural Roads, Mine Tailings, Tailings Dust Control,

Storage & Stock Piles, Stock Pile Dust Control, Stock Pile Capping. Stock Pile Stabilization, Power Plants, Facility Dust Control, Stock Pile Capping, Military Operations, Defense Compounds, Suppress Fugitive Dust etc.

This heavy haul military convoy road is being applied with KALMATRON® KF-D through the use of a standard water truck.

Without KALMATRON® KF-D unimproved gravel runways are susceptible to losing their soil and aggregate fines which causes raveling and erosion of the runway surface resulting in dust generation, aggregate decomposition, erosion, FOD and ultimately failure of the runway.

Here’s a look at the key BENEFITS and features of

· Initial Solubility of KF-D with water 100%

· The final product of hardening is insoluble even by acid or water containing salts.

· Complete Reducing of Blaining of standard mix

· The time of hardening is adjustable by different consumption of KF-D.

· KF-D has no influence on environment.

· Dries Transparent / Clear

· Non-Corrosive & Safe for All Equipment

· Non-Hazardous & Non-Toxic

· Dyes & Pigments can be Added for Color

· Simple & Easy to Apply

· Water Resistant

· Non-Flammable & Non-Volatile

· Dries Odorless

· Non-Slippery & Safe to Drive on Once Penetrated

· Non-Leaching (Will not continue to seep into soil or ground water)

· Dries Flexible / Elastomeric (Not Brittle)

· Alkaline Soil Resistant (Resists breakdown in alkaline soils)

· Non-Dissipating (Will not wash away with water once cured)

· Human, Animal, Marine Life & Vegetation Safe

· Biodegradable

· Cumulative Effect with Maintenance

· Non-Regulated for Transportation (Land/Sea/Air)

· Ultraviolet Ray Resistant

· Self-Mixes with Water for Diluting (Prior to applying to soil)

· Ecologically & Environmentally Safe

· PM10 & PM2.5 Compliant (Stops dust particles of 2.5+ microns in size)

· The applications of KF-D by injection or sorption treatment created a chemically changed structure with increased density and reduction of hydraulic conductivity or Coefficient of Permeability.

* The costs of the products are easily set-off against the savings made in water, diesel, man-power, servicing intervals and road maintenance, leaving an overall saving to the client. The use of additives makes concrete impervious to engine oils and diesel fuel;

Are any other Airports, Federal Highway, Stadiums etc.. using a newer product

href="http://www.kalmatron.com/files/Files1/KF-D/ADofKF-D.pdf" target="blank">http://www.kalmatron.com/files/Files...ADofKF-D.pdf

The application of KF-D and EMS treatment creates a chemically changed structure of soil and building materials liner with a reduction in hydraulic conductivity. The degree of improvement depends on initial density of the structure. For crumbling soil it is almost 100 times more effective than for untreated soil in stopping of leaks and moisture flow or seeping.

Application of Kalmatron® KF-D as an additive to concrete.

What does to concrete the admixture of Kalmatron® KF-D?

• concrete becomes more easy to work with, which helps streamline the structure of the concrete;

• enforces hydrophobic features of concrete and reduces water absorption by an average of 50%;

• brings higher density of concrete and significantly improves its resistance to aggressive environments, preventing the destruction of the core cement as a result of the gas, salt water and biological corrosion.

• increases the level of cement hydration in the process of manufacturing concrete structures;

• reduces adverse impact of external factors in the process of manufacturing concrete structures;

• increases the strength of concrete in the design age up to 30%;

• increases resistance to frost for extra 50 cycles;

• an additive in concrete does not corrode the fittings and does not impair the passivating action of concrete towards the steel reinforcement;

• non-toxic;

• fire and explosion safe.

In this case, the estimated consumption of Kalmatron KF-D is 2.5% by weight of cement.

• Standard – consumption of 10 kg per 1 cubic meter of concrete.

• Concentrated - consumption of 5 kg per 1 cubic meter.

Simpler way is to apply KF-D as it shown on

href="http://shieldcrete.homestead.com/KF-D-ADMIX.html?=1376943814852" target="blank">http://shieldcrete.homestead.com/KF-...=1376943814852

KALMATRON® KF-D designed as an admixture to the Cement’s Soils Containing Sealers of the CMS (Crumbled Material’s Sealant) for enhancement of soils consolidation with strength accelerating and any required level of liquid impermeability.

KF-D performs as a compactor of crumbled concrete and densifier of disintegrated and/or soggy soils.

KF-D provides stable consolidation of injected structures with increasing of compressive strength up to 40%.

KF-D improves liquid impermeability of Earth-Material’s Structures (EMS) and concrete/masonry building’s elements.

KF-D stabilizes the flowing of soggy soils of the fields, offshore, sinkholes, foundations, and etc.

KF-D is a costeffective solution that utilizes unusable structures to be restored up to impermeable to the liquids without the need of isolating membranes or water mitigating solutions and devices.

No Drying Shrinkage and post hardening deformations;

Exothermic heat is lower by 50%;

100% water impermeability of EMS and EBS at 3” to 5” thick layer;

Strong adhesion to any porous material;

Increased pumpability;

Increased workability;

Eliminates palpability;

No shrinkage cracks;

No cracks, flakes, efflorescence and slid areas;

No bleeding or oozing;

Highest resistance to climate corrosions;

Highest freeze-thaw resistance;

No curing is required.

It is correct about high probability of rock fill particles rearrangement, but unfortunately there is no universal recipe because every time situation is different. Very often ground stabilization solves the problem by soil premix with additive and placement rock fill after

href="http://www.kalmatron.com/5-KF-D.html" target="blank">http://www.kalmatron.com/5-KF-D.html

For areas with active filtration or high water table, KF-D must be injected.

The application of KF-D and EMS treatment creates a chemically changed structure of soil and building materials liner with a reduction in hydraulic conductivity. The degree of improvement depends on initial density of the structure. For crumbling soil it is almost 100 times more effective than for untreated soil in stopping of leaks and moisture flow or seeping.

Do not hesitate to ask about sample for your trials even on a job site.

This technology brings a new economical concept, where KALMATRON® reduces the cost per square foot of concrete up to 2 times. Our clients say:

”We can not afford to work without KALMATRON®.”

The most economical on The World Market.

With Best Regards,

Dilip Shah/Dr. Alex Rusinoff

NRD Industries. USA

WhatsApp & Viber: 0018483911248

E-mail :

href="mailto:nrdindustries@gmail.com">nrdindustries@gmail.com

Skype ID: dilipshah26

PRODUCTSLIST

href="http://www.kalmatron.com/files/PRODUCTSLIST.pdf" target="blank">http://www.kalmatron.com/files/PRODUCTSLIST.pdf

Visit us at:

href="http://www.greenbuiltconcrete.com" target="blank">www.greenbuiltconcrete.com NEW!

href="http://www.drivewayoverlay.com" target="blank">www.drivewayoverlay.com NEW!

href="http://www.kalmatron.com" target="blank">www.kalmatron.com

href="http://www.shieldcrete.com" target="blank">www.shieldcrete.com

href="http://www.shotcreteadmix.com" target="blank">www.shotcreteadmix.com

href="http://www.stuccowatreproof.com" target="blank">www.stuccowatreproof.com

href="http://www.parkingconcrete.com" target="blank">www.parkingconcrete.com

href="http://www.concreteadmix.com" target="blank">www.concreteadmix.com

href="http://www.wineryrepair.com" target="blank">www.wineryrepair.com

href="http://www.blockdegree.com" target="blank">www.blockdegree.com

href="http://www.seismicstar.com" target="blank">www.seismicstar.com

href="http://www.kalmatron.cn" target="blank">www.kalmatron.cn

href="http://www.nrdindustries.com" target="blank">www.nrdindustries.com

Attachments

■

Boring Boring Boring

This here thread is over 10 years old. Advertising has been as immense as it has been boring. Very little can possibly have been learned. Would the thread starter care to advise how many of his workers have contracted silicosis since the start of his quest? This will give the forum members some feedback on an otherwise laborious topic by giving an indication of the success of the thread. The bulk of the replies could have been written in Hindi and still overlooked by the forum members. ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Re: Quarry Dust Suppression

Dear Lyn

I have not found it in internet. Do you mean this one:

Guide to the Handling of Dusty Materials in Ports - Impact, prevention and control? ■

"Soil Before Treatment With Kalmatron® Kf-D And After"

Mrs. Dipali Shah-Pandya

N R D Industries

86 Commonweallth Ave

Piscataway, NJ 08854.

USA

E-mail : nrdindusties@gmail.com, nrd@juno.com

http://www.nrdindustries.com

You may visit http://www.nrdindustries.com to obtain this information

"Soil before treatment with KALMATRON® KF-D and after"

Dear Colleagues,

We're working with concretes, grouts and mortars. Dust reduction could be provided by KF-D premixed with the cement and sprayed and rolled down on ground to prevent dust emission. KALMATRON® KF-D designed as an admixture to the Cement’s Soils Containing Sealers of the CMS (Crumbled Material’s Sealant) for enhancement of soils consolidation with strength accelerating and any required level of liquid impermeability. KALMATRON® KF-D PROVIDES THE SOLUTION TO A WORLDWIDE NEED FOR BETTER AND SAFER ROADS.

Without KALMATRON® KF-D unimproved gravel runways are susceptible to losing their soil and aggregate fines which causes raveling and erosion of the runway surface resulting in dust generation, aggregate decomposition, erosion, FOD and ultimately failure of the runway.

BENEFITS

• Initial Solubility of KF-D with water is 100% .

• The final product of hardening is insoluble even by acid or water containing salts.

• Completely reduces Bubbling of standard mix.

• The time of hardening is adjustable by W/C ratio.

• KF-D is chemically passive with environmental mineralogy.

Environmental mineralogy of urban and disturbed landscapes including industrial settings, suburban settings, tourist settings and mine sites.

• KF-D is ideal for improving the compaction and impermeability of soil;

• Reduces hydraulic conductivity of most known soils up to 98.2%;

• When added to standard EMS mixes, it can be injected into sinkholes, foundations, tunnels, dams, wet and polluted soils;

• Improves binding with standard concrete fillers and particles of soil;

• Stops leaks and prevents future leaks by increasing density;

• Completely reduces bubbling of standard mixture;

• Hardening time is adjustable by using different amounts of KF-D

• KF-D does not affect the environment.

• Applications of KF-D by injection, premix, gunite or sorption treatment forms a chemically structured mass where consolidated particles involved as coarse filler. For areas with active filtration or high water table, KF-D must be injected.

Are any other Airborne, Airports, Federal Highway, Stadiums, Military Operations, Defense Compounds, Suppress Fugitive Dust etc.. This heavy haul military convoy road is being applied with KALMATRON® KF-D through the use of a standard water truck.using a newer product

http://www.kalmatron.com/files/Files...ADofKF-D.pdf

http://www.kalmatron.com/5-KF-D.html

With Best Regards,

Dilip Shah/Dr

NRD Industries. USA

WhatsApp : 0018483911248

Viber & Tango : 0018483911248 - Free calls Worldwide

E-mail : nrdindustries@gmail.com

Skype ID: dilipshah26

Visit us at:

www.kalmatron.com ■

"Soil Before Treatment With Kalmatron® Kf-D And After"

"Soil before treatment with KALMATRON® KF-D and after"

Dear Colleagues,

We're working with concretes, grouts and mortars. Dust reduction could be provided by KF-D premixed with the cement and sprayed and rolled down on ground to prevent dust emission. KALMATRON® KF-D designed as an admixture to the Cement’s Soils Containing Sealers of the CMS (Crumbled Material’s Sealant) for enhancement of soils consolidation with strength accelerating and any required level of liquid impermeability. KALMATRON® KF-D PROVIDES THE SOLUTION TO A WORLDWIDE NEED FOR BETTER AND SAFER ROADS.

Without KALMATRON® KF-D unimproved gravel runways are susceptible to losing their soil and aggregate fines which causes raveling and erosion of the runway surface resulting in dust generation, aggregate decomposition, erosion, FOD and ultimately failure of the runway.

BENEFITS

• Initial Solubility of KF-D with water is 100% .

• The final product of hardening is insoluble even by acid or water containing salts.

• Completely reduces Bubbling of standard mix.

• The time of hardening is adjustable by W/C ratio.

• KF-D is chemically passive with environmental mineralogy.

Environmental mineralogy of urban and disturbed landscapes including industrial settings, suburban settings, tourist settings and mine sites.

• KF-D is ideal for improving the compaction and impermeability of soil;

• Reduces hydraulic conductivity of most known soils up to 98.2%;

• When added to standard EMS mixes, it can be injected into sinkholes, foundations, tunnels, dams, wet and polluted soils;

• Improves binding with standard concrete fillers and particles of soil;

• Stops leaks and prevents future leaks by increasing density;

• Completely reduces bubbling of standard mixture;

• Hardening time is adjustable by using different amounts of KF-D

• KF-D does not affect the environment.

• Applications of KF-D by injection, premix, gunite or sorption treatment forms a chemically structured mass where consolidated particles involved as coarse filler. For areas with active filtration or high water table, KF-D must be injected.

Are any other Airborne, Airports, Federal Highway, Stadiums, Military Operations, Defense Compounds, Suppress Fugitive Dust etc.. This heavy haul military convoy road is being applied with KALMATRON® KF-D through the use of a standard water truck.using a newer product

http://www.kalmatron.com/files/Files...ADofKF-D.pdf

http://www.kalmatron.com/5-KF-D.html

With Best Regards,

Dilip Shah/Dr

NRD Industries. USA

WhatsApp : 0018483911248

Viber & Tango : 0018483911248 - Free calls Worldwide

E-mail : nrdindustries@gmail.com

Skype ID: dilipshah26

Visit us at:

www.kalmatron.com ■

Re: Quarry Dust Suppression

Best-Chem Ltd - we provide a design, build, supply and installtion service for complete foam based dust suppression systems in quarries. We are also manufacturers of speciality chemicals used for use with our systems.

Our contact details are

Best-Chem Ltd

Barracks Road

Sandy Lane Industrial Estate

Stourport

DY13 9QB

England

Tel +44 1299 827232

Fax +44 1299 827608

www.best-chem.co.uk ■

Quarry Dust Suppression

We are looking for experienced manufacturers of Dust Suppression Systems for a Limestone Quarry Project in the Middle East.

Please can you respond with your contact info and experience with this application.

Thank you. ■