7. Design Principles For Chute Design

7.1 Design Principle 1 – Prevent Plugging At Impact Points

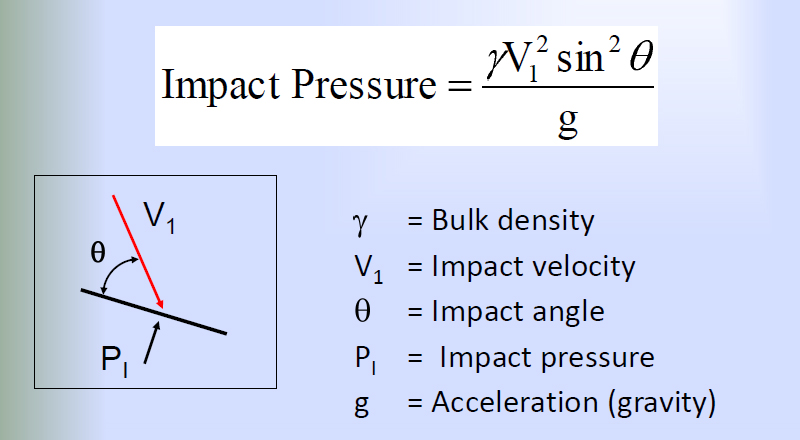

The chute face must be sufficiently smooth and steep to allow sliding and hence clean-off of the stickiest material that it has to handle. The impact pressure at any point that the material stream impacts the chute face is presented in Fig. 14.

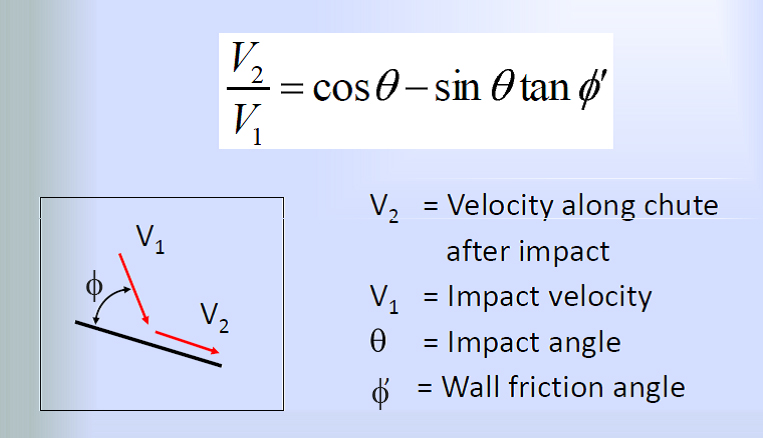

The velocity following an impact with the chute surface may be calculated from Fig. 15.

Stagnation and hence plugging will occur when V2 = 0 m/s. It is critical that the velocity at the point in question be accurately estimated. As the material moves through the chute it may be subjected to different acceleration forces such as sliding along the chute plates or free falling through the vertical section of a chute. The acceleration along a face of the chute is calculated as

And the velocity is calculated as

where: V0 = velocity at the start of the incline s = length of the incline. For free fall the velocity is calculated as

where: S = the height of the free fall g = acceleration due to gravity. For a section of the chute at a slightly different inclination, the starting velocity

where β is the inclination of the section. Acceleration over this section is

so that the exit velocity

The stream velocity in the belt direction:

The vertical component is

The impact pressure of the stream with the belt

|