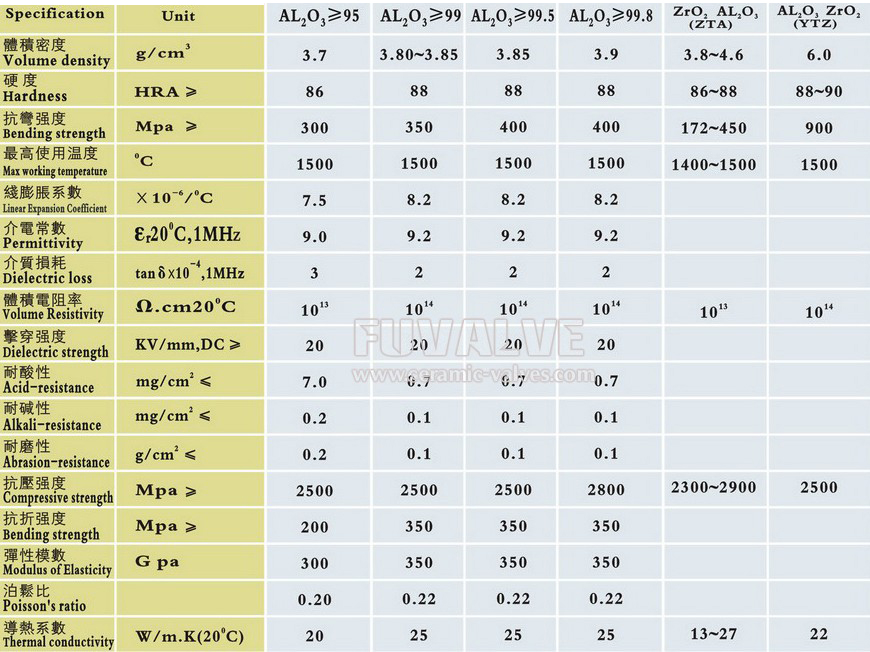

Properties Of Fine Ceramics

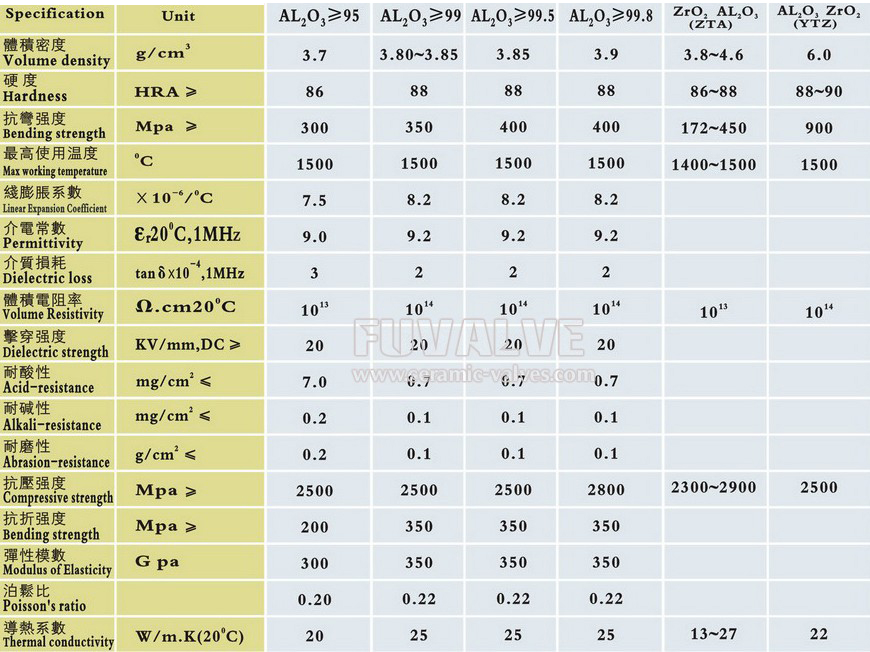

Physical/Chemical Properties of Fine Ceramics

Here is the Physical and chemical properties of fine ceramic for the one who may need.

href="https://forum.bulk-online.com/attachment.php?attachmentid=33857&d=1346144260" id="attachment33857" rel="Lightbox75743" target="blank">■

Ceramic Ball Valve

The ceramic lined valves used on the pipe.

For more information, please visit:

https://edir.bulk-online.com/profile...en-fuvalve.htm ■

Ceramic Products

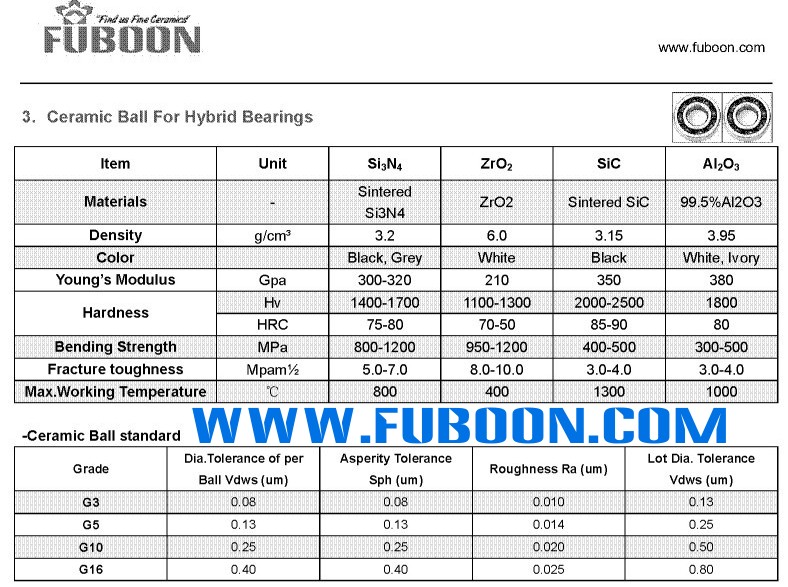

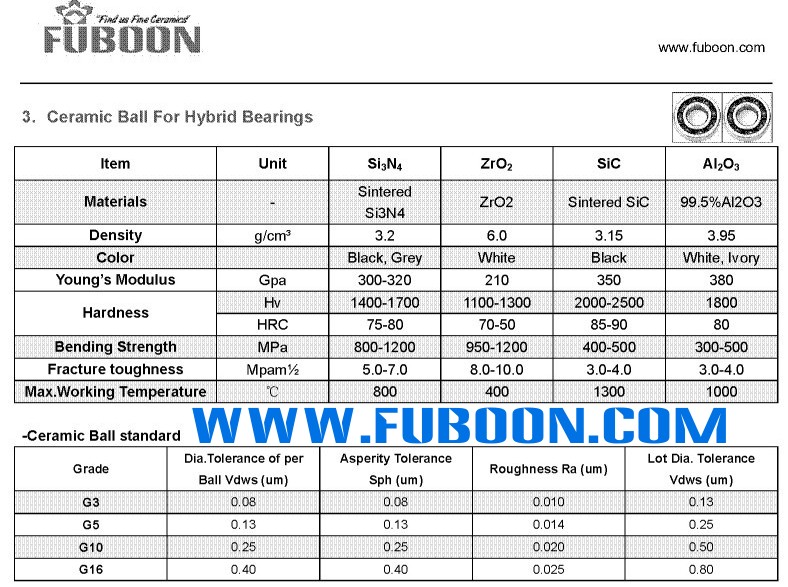

Ceramic hybrid ball bearings using ceramic balls

Ceramic bearing balls can weigh up to 40% less than steel ones, depending on size and material. This reduces centrifugal loading and skidding, so hybrid ceramic bearings can operate 20% to 40% faster than conventional bearings. This means that the outer race groove exerts less force inward against the ball as the bearing spins. This reduction in force reduces the friction and rolling resistance. The lighter balls allows the bearing to spin faster, and uses less energy to maintain its speed.

Click to enlarge the data sheet:

While ceramic hybrid bearings use ceramic balls in place of steel ones, they are constructed with steel inner and outer rings; hence the hybrid designation.

For more information, please visit:

https://edir.bulk-online.com/profile...ernational.htm ■

Ceramic Tube

Ceramic tube

With hign wear resistance and favorable erosion resistance,the ceramic tube is widely used in the high corrosive and high-temperature environment like thermal power plants,mining,metallurgy,cement plants,etc.

Size iameter 10mm to 200mm

iameter 10mm to 200mm

We can provide different types of the products according to customer's requirements.Just give us your drawing we'll produce the ceramic tubes accordingly.

For more information, please visit:

https://edir.bulk-online.com/profile...ernational.htm ■

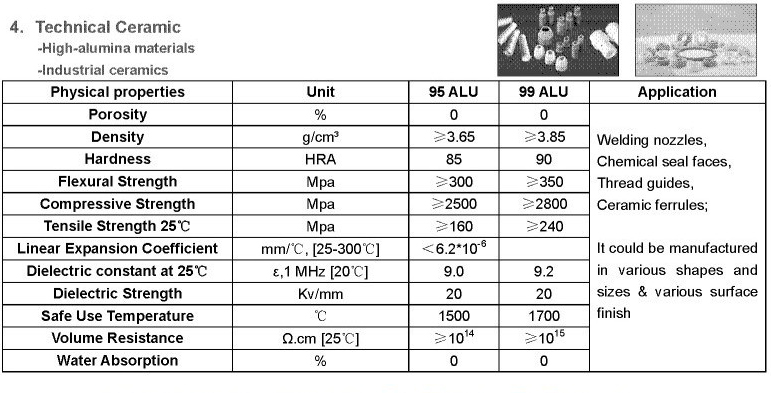

Ceramic Products From Fuboon

Ceramic Nozzles, Welding Nozzles

Features:

1) High density

2) Strong

3) Thermal shock resistant

4) Heat-resistant

5) Mainly used in welding machines and surface treatments

6) Electrical insulation

7) Fine surface

8) Ceramic nozzles do not wear easily

9) Acid-proof, alkali-proof

10) We can produce ceramic nozzles according to clients' specifications

and even according to molds or drawings provided by the client

Click to enlarge the data sheet:

For more information, please visit:

https://edir.bulk-online.com/profile...ernational.htm ■

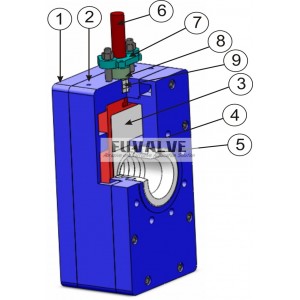

Ceramic Sliding Disc Valve

Ceramic Sliding Disc Valve for abrasive and corrosive mediums

Main specifications:

Nomunal pressure:1.06.3MPa

Nomunal diameter :DN40DN300

Suitable media: Desulfuration,Dusting,Coal injection,Silicon powder converying

Suitable temperature :-20500

1Ceramic to ceramic sealing

The Sliding disc valve trim consists of three ceramic parts,one sliding disc and two stationary ceramic seats.The sliding disc is moving vertically and sealing against the seat directly.Compared with the traditional gate valve, it has long service life for there is no dead-space free,impact or impulse.

2Abrasion resistant The hardness of the ceramic disc and seats is upto HRA88, maybe it is only less than Diamond.So the ceramic sliding disc valve has an outstanding performance in many high abrasion and wear applications.

3Corrosion resistant

Fine ceramic owns excellent chemical inertness , Almost no reaction with all chemical medium so the ceramic sliding disc valve can be excellent used to high-corrosion mediums. The design of sealing structure keep the medium from contacting the valve body cavity.

4High strength The ceramic disc is protected by a metal holder,and the stem drives the disc through the holder,and the ceramic disc will not damaged for sudden shock.

5Zero leakage

With many years experience in ceramics machining,zero leakage is ensured for its high accuracy,the surface roughness and flatness of the sealing face are less than 2um.And the ceramic disc and seats grinding against themselves when open/close,for that the tightness of the valve is enhanced.

6Without block

The mediums especially which contains solid particle will not block the valve for the through conduit design and the unique dead-space free structure, that is why the ceramic sliding disc valve is very suitable for the abrasive and/or corrosive conditions.

For more information, please visit:

https://edir.bulk-online.com/profile...en-fuvalve.htm

Google Search:

http://www.google.com/search?client=...UTF-8&oe=UTF-8

http://www.google.com/search?q=Fuval...=lnms&tbm=isch ■

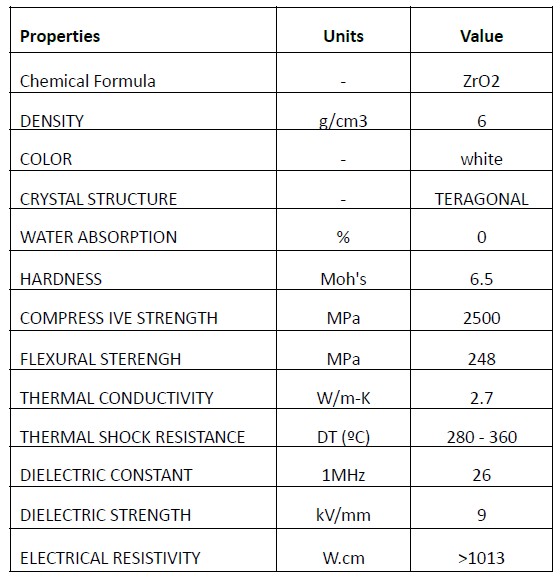

Zirconia Ceramics Components

Zirconia Ceramics Components

Introduction

Zirconium oxide occurs as monoclinic, tetragonal and cubic crystal forms. Densely sintered parts can be manufactured as cubic and/or tetragonal crystal forms. In order to stabilise these crystal structures, stabilisers such as magnesium oxide (MgO), calcium oxide (CaO) or yttrium oxide (Y2O3) need to be added to the ZrO2.

Other stabilisers sometimes used are cerium oxide (CeO2), scandium oxide (Sc2O3) or ytterbium oxide (Yb2O3).

Properties

FUBOON is good at yttria stabilized zirconia. Unlike other ceramic materials, zirconia is a material with very high resistance to crack propagation. Zirconium oxide ceramics also have very high thermal expansion and are therefore often the material of choice for joining ceramic and steel.

high fracture toughness

thermal expansion similar to cast iron

extremely high bending strength and tensile strength

high resistance to wear and to corrosion

low thermal conductivity

(click on picture to enlarge)

Industry

The range of applications for our zirconia ceramic used as nozzles,

sleeves, shafts, cutters in Industry as below;

Textile Industry

Medical

Paper Production Machines

Sand Mill Machines

Automotive

Plant Engineering

Metalworking

Pump and Fittings

Electrical and Electronic

Filling Machines

Products made from Zirconia

Bearing Technology in Automotive Engineering

Cutter for textile machines

Drawing Tools

Forming Applications

Seal Rings, Bearings and Sealing

Wire Drawing, Components for

Zirconium Oxide-stabilized Substrates

Zirconia Ball Valves

Plunger Shaft

For more information, please visit:

https://edir.bulk-online.com/profile...ernational.htm

Google Search:

http://www.google.com/search?client=...UTF-8&oe=UTF-8

http://www.google.com/search?q=FUBOO...=lnms&tbm=isch ■

Ceramic Lined Ball Valve For Abrasive Application

Due to the very high level hardness of the fine ceramic materials,the excellent property of ceramic lined valves can solve the problem of abrasion caused by some high abrasive mediums.

href="https://forum.bulk-online.com/attachment.php?attachmentid=37951&d=1385955632" id="attachment37951" rel="Lightbox81247" target="blank">■

Ceramic Lined Ball Valve

Very excellent for abrasive applications. ■

Untitled

The ceramic disc sliding valve is very excellent for the application with high pressure with abrasion. ■

Zirconia Ceramics Components

Zirconia is most famous high-performance material among all oxide ceramics. Ceramic components made out of Zirconia generally consist of Zirconia as basic material doped with some percentage of other oxides like Yttria (Y2O3) or Magnesia (MgO). Depending on doping material different material properties could be achieved because of influencing the Yttria's microstructure. The "ceramic steel" titled Zirconia is doped with Yttria forming an ultra-fine ductile structure with sub-micron grain formation leading to enormous bending strengths. Magnesia doped qualities are less strong also showing a coarser microstructure.

Zirconia is characterized through its tribological performance (friction and wear) in moving applications and furthermore:

Excellent fracture toughness

Very good wear resistance

High corrosion stability

Low thermal conductivity

CTE in range of steel ■

Untitled

Main specifications:

Nomunal pressure:1.06.3MPa

Nomunal diameter :DN40DN300

Suitable media: Desulfuration,Dusting,Coal injection,Silicon powder converying

Suitable temperature :-20500

1Ceramic to ceramic sealing

The Sliding disc valve trim consists of three ceramic parts,one sliding disc and two stationary ceramic seats.The sliding disc is moving vertically and sealing against the seat directly.Compared with the traditional gate valve, it has long service life for there is no dead-space free,impact or impulse.

2Abrasion resistant The hardness of the ceramic disc and seats is upto HRA88, maybe it is only less than Diamond.So the ceramic sliding disc valve has an outstanding performance in many high abrasion and wear applications.

3Corrosion resistant

Fine ceramic owns excellent chemical inertness , Almost no reaction with all chemical medium so the ceramic sliding disc valve can be excellent used to high-corrosion mediums. The design of sealing structure keep the medium from contacting the valve body cavity.

4High strength The ceramic disc is protected by a metal holder,and the stem drives the disc through the holder,and the ceramic disc will not damaged for sudden shock.

5Zero leakage

With many years experience in ceramics machining,zero leakage is ensured for its high accuracy,the surface roughness and flatness of the sealing face are less than 2um.And the ceramic disc and seats grinding against themselves when open/close,for that the tightness of the valve is enhanced.

6Without block

The mediums especially which contains solid particle will not block the valve for the through conduit design and the unique dead-space free structure, that is why the ceramic sliding disc valve is very suitable for the abrasive and/or corrosive conditions.

For more information, please visit:

https://edir.bulk-online.com/profile...en-fuvalve.htm

Google Search:

http://www.google.com/search?client=...UTF-8&oe=UTF-8

http://www.google.com/search?q=Fuval...=lnms&tbm=isch

ceramic sliding disc valve is a full lined ceramic valve which works like gate valve but with more excellent performance. ■

Re: Ceramic Lined Ball Valve

fine ceramics used for abrasive applications is very excellent. ■

Ceramic Lined Valve

As an abrasion resistant and corrosion resistant valve, ceramic lined ball valve has very excellent performance for abrasive mediums and corrosive mediums.The ceramic lined valve has been used in quartz pneumatic conveying, coal powder pneumatic conveying, Silica powder pneumatic conveying, Lime powder pneumatic conveying ,Calcium cyanamide pneumatic conveying and etc.

From the below material property you'll find the hardness,strength and other performance of the different structure ceramics.

FUVALVE Structural Ceramic Ball Valves(Al2O3 or ZrO2 Ceramic)

Advantages of structural ceramic ball valves include hi-economy, long life (2~4 times of Titanium Valves), increase resistance to corrosion, high temperature, wear and erosion etc.. They are commonly used in transportation systems of various acid, alkaline or saline gases, solutions, high working temperature steams and slurries, in the lines of oil industry, metallurgy, papermaking, power station, refinery, etc. Structural ceramic ball valves are the ideal substitute for titanium and monel valves in corrosive environments. There are four types of driving performances, manual, pneumatic, pneumatic-spring return and electric. Various special valves can be designed on demand. Furthermore, various high wear-resistant, corrosion-resistant and high temperature-resistant ceramic components, hydraulic pressure sealing components can be provided as well.

Properties of FUVALVE Structural Ceramic Ball Valves

Typical properties of structural ceramic ball valves include:

Wear and corrosion resistance

The valve ball, valve seat and inner lining are all made of structural ceramics with hardness of HRA87 or above. So structural ceramic ball valves can withstand the impact of Hi-speed liquids and hard grains, displaying excellent performance on wear and corrosion resistance.

Corrosion resistance

The valve ball, valve seat and the inner lining are all made of structural ceramics. The structural ceramics have excellent corrosion-resistance, except to glass-liquor and hydrofluoric acid.

Long working life

The static pressure test showed no leakage after long times opening-closing.

Wide-range of applications

Structural ceramic ball valves are applicable to various acid, alkaline or saline solutions, gaseous media, etc. Hard sealing ball valves can also be used in media with particles and fibers.

Excellent for the mediums:

Acetic Acid

Green Liquor

Sand / Tailings Slurry

Alumina Hydrate

Gypsum Slurry

Sodium Benzoate

Aluimina Powder

Hydrochloric Acid

Sodium Carbonate

Alumina Chloride

Hydrofluoric Acid

Sodium Chlorate

Ammonia

Hydrogen Peroxide

Sodium Chloride

Ammonium Carbonate

Kaolin Slurry

Sodium Cyanide

Ammonium Chloride

Kerosene

Sodium Fluoride

Ammonium Fluoride

Lime / Limestone Slurry

Sodium Hydroxide

Ammonium Silicate

Magnesium Hydroxide

Sodium Hypochlorite

Anatase Slurry

Magnesium Oxide Slurry

Sodium Nitrate

Aniline

Magnesium Sulfate

Sodium Sulfate

Ash Slurry

Mangesium Slurry / Ore

Soot Slurry

Bauxite Slurry

Mercuric Chloride

Steam

Benzyl Chloride

Methanol

Sulfur Dioxide

Black Liquor

Methyl Acetone

Sulfuric Acid

Boric Acid

Methyl Chloride

Talcum Water

Brine

Methyl Ethyl Ketone

Tarnic Acid

Calcium Carbonate

Methylene Chloride

Titanium Dioxide

Calcium Chlorate

Milk of Lime

Titanium Tetrachloride

Calcium Chloride

Mother Liquor

Toluene

Calcium Hypochlorite

Napthalene

Trichloroethane

Calcium Sulfate

Natural Gas

Turpentine

Carbon Slurry

Nitric Acid

Waste Acids

Chlorine (Wet)

Oleum

Wool Fines

Chlorosilane Vapor

Papered Slurry

Xylene

Chromic Acid

Petroleum

Zinc Sulfate

Citric Acid

Phenol

Trichlorosilane

Clay Slurry

Phosphoric Acid

Silicon Tetrachloride

Copper Chloride

Potassium Bromate

Copper Cyanide

Potassium Carbonate

Copper Sulfate

Potassium Chlorate

Cuprous Chloride

Potassium Chloride

Ethanol

Potassium Dichromate

Ethyl Amine

Potassium Perchlorate

Ethyl Ether

Potassium Permanganate

Ferric Chloride

Potassium Sulfate

Ferrous Sulfate

Precipitated Calcium

Flue Gas

Carbonate (PCC)

Flyash (Wet and Dry)

Slurry

Formic Acid

Recycled Paper

*For the corrosive medium without abrasive particle we suggest to use PFA lined valve,PTFE lined valve or FEP lined valve.

*For the medium contains both of corrosive or abrasive,the ceramic ball valve will be the best choice.

*For high-ware solid particles or powder,the ceramic lined ball valve or orbit ball valve will be the best choice.

For more information, please visit:

https://edir.bulk-online.com/profile...en-fuvalve.htm

The valve is full lined with fine ceramics which made of Zro2 ceramic or Al2O3 ceramic,the hardness level of the material only next to diamond. ■

Ceramic Blade

Zirconia Ceramics Components

Introduction

Zirconium oxide occurs as monoclinic, tetragonal and cubic crystal forms. Densely sintered parts can be manufactured as cubic and/or tetragonal crystal forms. In order to stabilise these crystal structures, stabilisers such as magnesium oxide (MgO), calcium oxide (CaO) or yttrium oxide (Y2O3) need to be added to the ZrO2.

Other stabilisers sometimes used are cerium oxide (CeO2), scandium oxide (Sc2O3) or ytterbium oxide (Yb2O3).

Properties

FUBOON is good at yttria stabilized zirconia. Unlike other ceramic materials, zirconia is a material with very high resistance to crack propagation. Zirconium oxide ceramics also have very high thermal expansion and are therefore often the material of choice for joining ceramic and steel.

high fracture toughness

thermal expansion similar to cast iron

extremely high bending strength and tensile strength

high resistance to wear and to corrosion

low thermal conductivity

(click on picture to enlarge)

Industry

The range of applications for our zirconia ceramic used as nozzles,

sleeves, shafts, cutters in Industry as below;

Textile Industry

Medical

Paper Production Machines

Sand Mill Machines

Automotive

Plant Engineering

Metalworking

Pump and Fittings

Electrical and Electronic

Filling Machines

Products made from Zirconia

Bearing Technology in Automotive Engineering

Cutter for textile machines

Drawing Tools

Forming Applications

Seal Rings, Bearings and Sealing

Wire Drawing, Components for

Zirconium Oxide-stabilized Substrates

Zirconia Ball Valves

Plunger Shaft

For more information, please visit:

https://edir.bulk-online.com/profile...ernational.htm

Google Search:

http://www.google.com/search?client=...UTF-8&oe=UTF-8

http://www.google.com/search?q=FUBOO...=lnms&tbm=isch

Zirconia ceramic component for industry components. ■

Ceramic Blade

Ceramic hybrid ball bearings using ceramic balls

Ceramic bearing balls can weigh up to 40% less than steel ones, depending on size and material. This reduces centrifugal loading and skidding, so hybrid ceramic bearings can operate 20% to 40% faster than conventional bearings. This means that the outer race groove exerts less force inward against the ball as the bearing spins. This reduction in force reduces the friction and rolling resistance. The lighter balls allows the bearing to spin faster, and uses less energy to maintain its speed.

Click to enlarge the data sheet:

While ceramic hybrid bearings use ceramic balls in place of steel ones, they are constructed with steel inner and outer rings; hence the hybrid designation.

For more information, please visit:

https://edir.bulk-online.com/profile...ernational.htm

Fine ceramic blade made of Zirconia grinding by diamond grinding wheel,high level hardness,top quality edge. ■

Ceramic Lined Ball Valve

Ceramic lined ball valve for abrasive particle Pneumatic Conveying and almost all abrasive applications.

As an abrasion resistant and corrosion resistant valve, ceramic lined ball valve has very excellent performance for abrasive mediums and corrosive mediums.The ceramic lined valve has been used in quartz pneumatic conveying, coal powder pneumatic conveying, Silica powder pneumatic conveying, Lime powder pneumatic conveying ,Calcium cyanamide pneumatic conveying and etc.

From the below material property you'll find the hardness,strength and other performance of the different structure ceramics.

FUVALVE Structural Ceramic Ball Valves(Al2O3 or ZrO2 Ceramic)

Advantages of structural ceramic ball valves include hi-economy, long life (2~4 times of Titanium Valves), increase resistance to corrosion, high temperature, wear and erosion etc.. They are commonly used in transportation systems of various acid, alkaline or saline gases, solutions, high working temperature steams and slurries, in the lines of oil industry, metallurgy, papermaking, power station, refinery, etc. Structural ceramic ball valves are the ideal substitute for titanium and monel valves in corrosive environments. There are four types of driving performances, manual, pneumatic, pneumatic-spring return and electric. Various special valves can be designed on demand. Furthermore, various high wear-resistant, corrosion-resistant and high temperature-resistant ceramic components, hydraulic pressure sealing components can be provided as well.

Properties of FUVALVE Structural Ceramic Ball Valves

Typical properties of structural ceramic ball valves include:

Wear and corrosion resistance

The valve ball, valve seat and inner lining are all made of structural ceramics with hardness of HRA87 or above. So structural ceramic ball valves can withstand the impact of Hi-speed liquids and hard grains, displaying excellent performance on wear and corrosion resistance.

Corrosion resistance

The valve ball, valve seat and the inner lining are all made of structural ceramics. The structural ceramics have excellent corrosion-resistance, except to glass-liquor and hydrofluoric acid.

Long working life

The static pressure test showed no leakage after long times opening-closing.

Wide-range of applications

Structural ceramic ball valves are applicable to various acid, alkaline or saline solutions, gaseous media, etc. Hard sealing ball valves can also be used in media with particles and fibers.

Excellent for the mediums:

Acetic Acid

Green Liquor

Sand / Tailings Slurry

Alumina Hydrate

Gypsum Slurry

Sodium Benzoate

Aluimina Powder

Hydrochloric Acid

Sodium Carbonate

Alumina Chloride

Hydrofluoric Acid

Sodium Chlorate

Ammonia

Hydrogen Peroxide

Sodium Chloride

Ammonium Carbonate

Kaolin Slurry

Sodium Cyanide

Ammonium Chloride

Kerosene

Sodium Fluoride

Ammonium Fluoride

Lime / Limestone Slurry

Sodium Hydroxide

Ammonium Silicate

Magnesium Hydroxide

Sodium Hypochlorite

Anatase Slurry

Magnesium Oxide Slurry

Sodium Nitrate

Aniline

Magnesium Sulfate

Sodium Sulfate

Ash Slurry

Mangesium Slurry / Ore

Soot Slurry

Bauxite Slurry

Mercuric Chloride

Steam

Benzyl Chloride

Methanol

Sulfur Dioxide

Black Liquor

Methyl Acetone

Sulfuric Acid

Boric Acid

Methyl Chloride

Talcum Water

Brine

Methyl Ethyl Ketone

Tarnic Acid

Calcium Carbonate

Methylene Chloride

Titanium Dioxide

Calcium Chlorate

Milk of Lime

Titanium Tetrachloride

Calcium Chloride

Mother Liquor

Toluene

Calcium Hypochlorite

Napthalene

Trichloroethane

Calcium Sulfate

Natural Gas

Turpentine

Carbon Slurry

Nitric Acid

Waste Acids

Chlorine (Wet)

Oleum

Wool Fines

Chlorosilane Vapor

Papered Slurry

Xylene

Chromic Acid

Petroleum

Zinc Sulfate

Citric Acid

Phenol

Trichlorosilane

Clay Slurry

Phosphoric Acid

Silicon Tetrachloride

Copper Chloride

Potassium Bromate

Copper Cyanide

Potassium Carbonate

Copper Sulfate

Potassium Chlorate

Cuprous Chloride

Potassium Chloride

Ethanol

Potassium Dichromate

Ethyl Amine

Potassium Perchlorate

Ethyl Ether

Potassium Permanganate

Ferric Chloride

Potassium Sulfate

Ferrous Sulfate

Precipitated Calcium

Flue Gas

Carbonate (PCC)

Flyash (Wet and Dry)

Slurry

Formic Acid

Recycled Paper

*For the corrosive medium without abrasive particle we suggest to use PFA lined valve,PTFE lined valve or FEP lined valve.

*For the medium contains both of corrosive or abrasive,the ceramic ball valve will be the best choice.

*For high-ware solid particles or powder,the ceramic lined ball valve or orbit ball valve will be the best choice. ■