Directing Flow

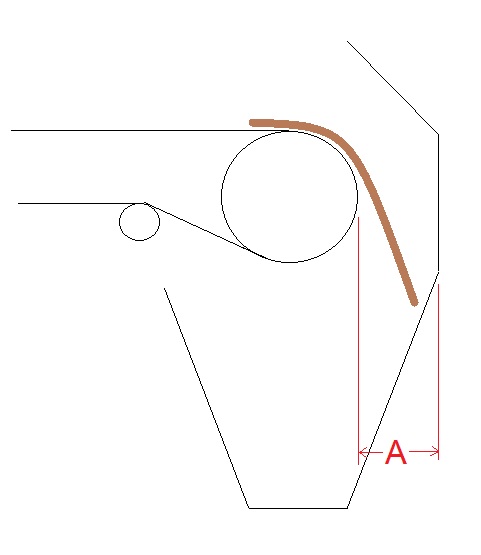

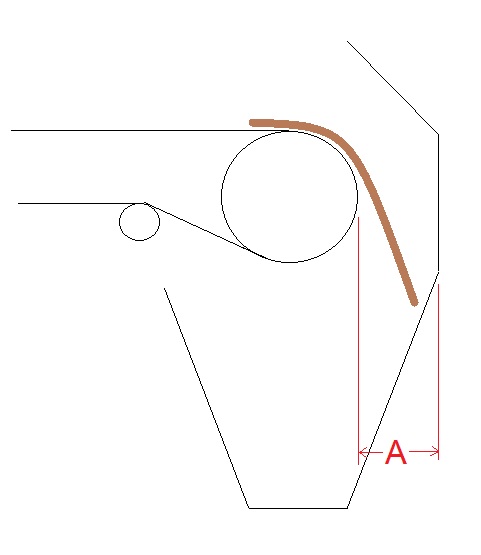

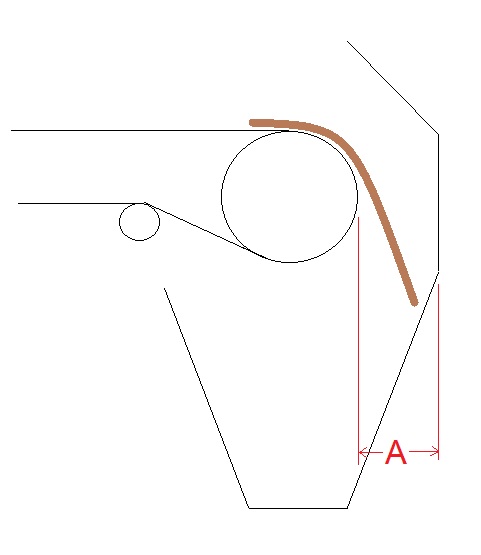

I have a conveyor for minerals and i want to make a discharge chute. I want to know if there is a formula to calculate the distance A (see photo) or there is a general rule. A distance of 300mm is it good or it is to narrow? The belt speed is 1m/sec, drive drum is 370mm, belt width=650mm, through set = 30degree.

An important consideration in chute design is where the flow stream is going. In this case it is not clear what the objective is in constructing a 'chute' of the form sketched. The impact of the flow stream to reverse its direction will give inevitable wear and attrition. Why not simply shorten the conveyor or move the outlet, to allow the flow to pass cleanly through the outlet without touching the walls if there is no other factor to consider. There is a wealth of information available on chute design, see notes by Alan Roberts on the web. Generally, these favour 'leading' the flow stream in a way to minimise impact and suit the following process, i.e. matching the linear speed of a receiving belt conveyor. ■

Dropsy Days.

Trough angle ought to be irrelevant. At 1ms-1 you are working back in the good old days of Anglo American when it needed boardroom level permission to jack up a belt to 1.5ms-1 . There is a low speed trajectory situation and you will have to check it, since the head drum is so small. As Lynn says why not drop straight onto the equipment below: whatever that might be. ■

Conveyor Chutes

I have a conveyor for minerals and I want to make a discharge chute.

I want to know if there is a formula to calculate the distance A (see photo)

or there is a general rule.

A distance of 300mm-is it good or it is to narrow?

The belt speed is 1m/sec, drive drum is 370mm,

belt width=650mm, through set = 30degree.

You are overlooking the big issue and not seeing the problem!!!!

The head pulley is too far forward and you are

trying to bypass the job of the transfer point/tail pulley.

The arc of the material leaving the head pulley should impact

the center of the tail pulley impact idlers or impact bars.

Pay attention to detail and it will all fall into in place.

Help us, to help you help us help you!!! ■

Re: Chute Design

Calculating the material trajectory is a fundamental step in designing a transfer, how to use the trajectory calculation to get the best outcomes as far as chute performance is also fundamental. It is quite a complex process but you can either purchase our book "The Transfer Chute Design Manual" or do research as others have done on how to calculate trajectories.

Cheers

Colin Benjamin

Gulf Conveyor Systems P/L

www:conveyorsystemstechnology.com ■

Check For Projectile

The head pulley is too far forward and you are

trying to bypass the job of the transfer point/tail pulley.

The arc of the material leaving the head pulley should impact

the center of the tail pulley impact idlers or impact bars.

Pay attention to detail and it will all fall into in place.

Help us, to help you help us help you!!!

The size will depend on the material to be handled and the discharge trajectory. If the material is mineral stone box can be given and the size of chute can be economized, if coal or any such flammable material is to be conveyed then avoid stone box. Also check for the trajectory( which will depend on Speed). Refer CEMA or IS:11592. ■

Re: Chute Design

I have a conveyor for minerals and i want to make a discharge chute. I want to know if there is a formula to calculate the distance A (see photo) or there is a general rule. A distance of 300mm is it good or it is to narrow? The belt speed is 1m/sec, drive drum is 370mm, belt width=650mm, through set = 30degree.

Refer CEMA. You will find how to calculate trajectory. ■

Chute Design

Dear Experts.

I have a conveyor for minerals and i want to make a discharge chute. I want to know if there is a formula to calculate the distance A (see photo) or there is a general rule. A distance of 300mm is it good or it is to narrow? The belt speed is 1m/sec, drive drum is 370mm, belt width=650mm, through set = 30degree.

href="https://forum.bulk-online.com/attachment.php?attachmentid=32867&d=1338394818" id="attachment32867" rel="Lightbox74551" target="blank"> ■

■