Photos Attached

Dear all,

Please find the photos attached for this problematic conveyor.

Though when the belt is purchased

1) the ply to ply ; ply to rubber adhesion properties satisfied the minimum requirements

2) there is no ply seperation at other places

We are not getting satisfied life of vulcanizing joints only in this conveyor.

The plies are looking very clean and not having coating of rubber, when they are opened for vulcanizing. I feel plies are not getting enough bonding with vulcanizing solution & compounds.

The other conveyors with same specifications, same manufacturer and same mechanicals installed are running fine.

I have taken this issue to the belt supplier with couple of times but not getting response.

Are my assumptions are correct?

Regards,

Attachments

■

Re: Vulcanizability Of Conveyor Belts

Take this to a(nother) reputable manufacturer, ask, they'll be EAGER to find a reason I feel... The more with some hope of becoming a replacement???

Rubber mix, pulley dia. , speed, T1& T2 forces, life till now will be surely discussed.

Regards

Roland ■

Conveyor Belt Splicing

Dear sganesh,

the problem of your splicing would be the following reason,

the rubber of the conveyor belt would be over-vulcanized, and the rubber lost his performance of adhision. Usully the temprature of vulcanizing is around 140 centigrade, if the temperature is much high or the vulcanizing time is much to longer than 20 munites, or the the belt was vulcanized time and time again, the rubber will lose the performance of adhision.

inforubber@gmail.com

www.frontindustry.com ■

Re: Vulcanizability Of Conveyor Belts

Thanks a lot for your replies.

Now I have few other doubts.

If during vulcanizing power is failed, how is it rectified ?

i.e., for example, assume that a conveyor vulcanizing ( it is also termed as cooking by western countries ) of a splicing needs 60 minutes, and power is went off at say 25 minutes.

When the power is resumed back, should the vulcanizing to be done for 60 minutes or 35 minutes?

Thanks & regards, ■

Splicing Difficulties

Of course usual Vulcanizing Presses doesn't make any record of the process data.

In this case you have to rely the mechanical quality of the Press (pressure system, flatness, uniformity of temperature etc.) but mainly also on the reliability of the operators.

During the curing time the operators are waiting and checking the temperature and the pressure on the visual gauges. If they are playing on their mobile phone like you can see in many countries today there is a big risk that something is going wrong.

If you have a break down of the power normally you can continue the process without any problems if the temperature didn't discrease too much (-10°C is OK). If it's more you have to decide to add some time or to make a new splice. But without any electronic record it's difficult to know.

That's why we decided to develop a special electronic control unit capable to check and store all the process data. This new control unit will restart automatically if the temperature decrease is not beyound the programmable limits. Furhter you can check the grafics to be sure.

In your special case I will recommend to use the Super-Screw fasteners which is the first mechanical fastener made of textile and rubber with most of the advantages of a hot splice. Many belt users will confirm it.

You will find some information about it on our web site or on previous threads.

Edgar Jakob

MLT GmbH

www.mlt-eu.com ■

Splice Kit Compatibility With Parent Belt

Often "Hot Belts" are constructed from EDPM compounds. The EDPM rubbers may take a Peroxide cure rather than a typical Sulfur cure of conventional belts.

Check your splice kit to determine if it is compatible.

What is the heat rating of the belt being spliced? ■

Re: Vulcanizability Of Conveyor Belts

Thank You all!

The conveyor mentioned here carries the HBI ( Hot Briquette Iron ) at 100 deg centigrade and the conveyor is purchased to with stand 120 deg celcius.

Thank you all once again & best regards, ■

Re: Vulcanizability Of Conveyor Belts

120 C is not sufficiently hot to require EDPM. However, did you check to determine the compound in use in the belt and the composition of the splice kit? ■

Re: Vulcanizability Of Conveyor Belts

Thank you Mr.Nordel.

We are using same vulcanizing material at other conveyors ( having same application and mechanicals ) and their joints are giving good life. But not in this conveyor. ■

Re: Vulcanizability Of Conveyor Belts

Thank you Mr.Nordel.

We are using same vulcanizing material at other conveyors ( having same application and mechanicals ) and their joints are giving good life. But not in this conveyor.

So I suspect that the plies used in this conveyor is not getting adequate bonding with the vulcanizing material.

Regards, ■

Re: Vulcanizability Of Conveyor Belts

Dear Sir:

Two responses to your questions:

1. Usually, when the plies strip off easily it is because there is little adhesion. If the fabric is "bright" (i.e. white in color) it usually means that there is little fabric treatment in that area. In this case, the splicer can treat the fabric with a "primer" to insure better adhesion.

2. You asked about the loss of power. Generally, if power is lost during the first half of the cure, it is best to start over from the beginning. If the power is lost during the second half of the cure, you can continue with the remaining time after the power is restored. However, this is only if there has been full pressure on the vulcanizer for the complete period of the cure and loss of power. ■

Re: Vulcanizability Of Conveyor Belts

Thanks a lot Mr.Ronf,

Now-a-days the belt manufacturers are not advising the use of any solvent or primers for cleaning the plies. They are advising only to use buffing and soft brush.

Request your comment on the above.

Regards, ■

Re: Vulcanizability Of Conveyor Belts

Dear Sir:

You are very correct about not using solvents to clean the plies or splice materials. I was not writing about this. Rather I was stating that sometimes you need to add an extra step in preparing the plies for greater adhesion.

When the plies have an insufficient amount of RLF treatment, they will appear white after the rubber is removed. Various companies have a "primer" that will restore this treatment to create a greater adhesion.

You do not need to do this on many belts. However, there are some instances where this will be very helpful in assuring adhesion. Your belt may be an example of this. ■

Re: Vulcanizability Of Conveyor Belts

Thank you Mr.Ronf,

Could you please explain about "RLF treatment" ?

Thanks a lot & regards, ■

Re: Vulcanizability Of Conveyor Belts

Dear Sir:

Every belt manufacturer uses an RLF treatment to insure adhesion between the plies of a conveyor belt. This treatment turns the fabric from a white color to a reddish color.

When the splicing company strips the belt for a splice, the fabric should remain a reddish color.

If the fabric is white, the RLF treatment on the belt was inferior. Therefore, if a splicing company does nothing to the fabric, The splice will fail.

If you would like further information, I would be glad to enter into a consulting agreement with you to insure better splice adhesion. ■

Re: Vulcanizability Of Conveyor Belts

So I suspect that the plies used in this conveyor is not getting adequate bonding with the vulcanizing material.

'Same application and mechanicals', but also the same belt? I advise to get splicing materials from the belt manufacturer, designed for the specific belt installed. One heat resistant belt is not the other, even when the same base polymer is used.

True, but if you mess up the splice area during the job, you need to. Clean and allow to dry properly, often forgotten. Same goes for solutions and primers: allow to dry! Also often: less use is better, so read the application manual carefully, another thing many vulcanisers don't do.

The worst thing to do is to buff the fabrics! No manufacturer will advise so. This is only done on cold vulcanising, but when buffing fabrics for hot vulcanising, you'll remove the RLF coating and actually reduce adhesion. Secondly you'll damage the fabrics reducing tensile strength. ■

Re: Vulcanizability Of Conveyor Belts

Dear Mr.rvoijen & Mr.Ronf & other experts,

A) We need buffing to remove the left out rubber patches when the steps are made to get plain surface. Is there any other method other than buffing? I was advised not to damage the plies & RLF component while buffing. I do agree. But some times people may do mistakes.

B) Can ageing of belt affect the RLF coating? Is there any suitable chemicals available to improve the quality of RLF coating prior to apply the hot vulcanizing compounds?

Thanks to all for sharing your high experience & valuable knowledge.

Regards, ■

Re: Vulcanizability Of Conveyor Belts

A) We need buffing to remove the left out rubber patches when the steps are made to get plain surface. Is there any other method other than buffing? I was advised not to damage the plies & RLF component while buffing. I do agree. But some times people may do mistakes.

As Rob van Oljen has advised, you do not need buffing to the extent that you remove the rubber patches - only the rough edges on any patches left behind when plys are seperated. You are after an "even" surface, any whitened area of fabric will result in a lessening of bond. There is no room for mistakes when preparing a fabric splice

Doug Ellis ■

Re: Vulcanizability Of Conveyor Belts

Dear Experts,

In the previous posts, does the "RLF" relates to the "Resorcinol (R), formaldehyde (F) and latex (L) which is known as RFL" ? What are the factors deciding the performance ( or quality ) of RFL ?

Thanks & best regards, ■

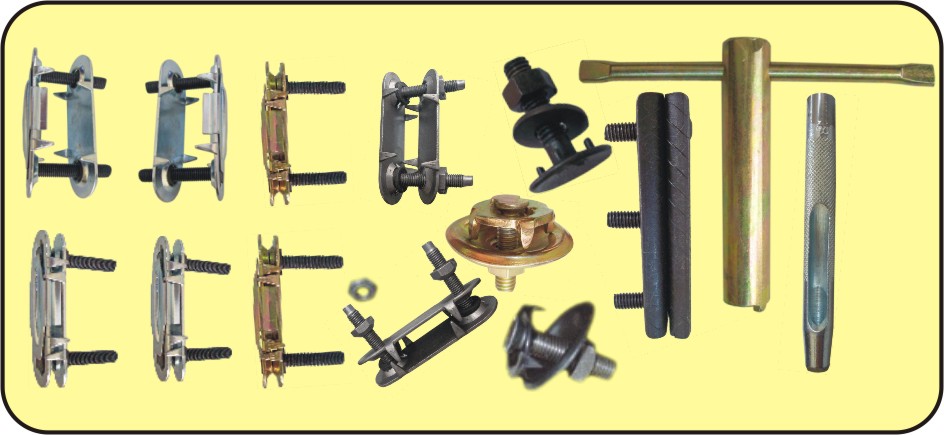

Conveyor Belt Fasteners

href="showthread.php?p=65621#post65621" rel="nofollow">

The conveyor mentioned here carries the HBI ( Hot Briquette Iron ) at 100 deg centigrade and the conveyor is purchased to with stand 120 deg celcius.

Thank you all once again & best regards,

Dear sir,

We wish to introduce ourselves as manufacturers of complete range of

Conveyor Belt Fasteners Plate Type ,Oval Belt Fasteners & Elevator Buckets

Bolt for domestic and exports markets as per IS 10288:1982 for Joining

rubber conveyor belts used in Minings,Cement,thermal,chemical

plants,Qerrying,road constructions,stone crusshing etc as follows:

1.Conveyor Belt Fastener No.1

2.Conveyor Belt Fastener No.1 1/2.

3.Conveyor Belt Fastener No. 2.

4.Conveyor Belt Fastener No 2 1/2.

5.Conveyor Belt Fastener No. 3 .

6.Oval Belt Fastener 3/8X11/2 ", 3/8X2",5/16X11/4"

7.Elevator Bucket Bolts 5/16X1"-11/4',3/8 X11/2",1/4X1"

8.L Type Mild Steel Kurling Type Fasteners

9.BOLT TIGTENING KEY

10.BOLT BREAKERS

We are ISO : 9001:2000 certified company.

We always abide contract and endeavor to offer high quality products and

reasonable price. We assure you our best of attention and services always.

Please visit our website :

href="http://www.premierudyog.org" target="blank">www.premierudyog.org for details ofour product range.

With regards.

Param vir singh.

M/s.Premier udyog,

11069/1,Street No.- 8,

Partap Nagar,Industrial Area-B,

Ludhiana-141003.

India.

Phones:91-161-2537541,3021941.

Fax: 91-161-2545377.

Cell:098140 26062.

E.Mail aram0377@gmail.com

aram0377@gmail.com

Attachments

■

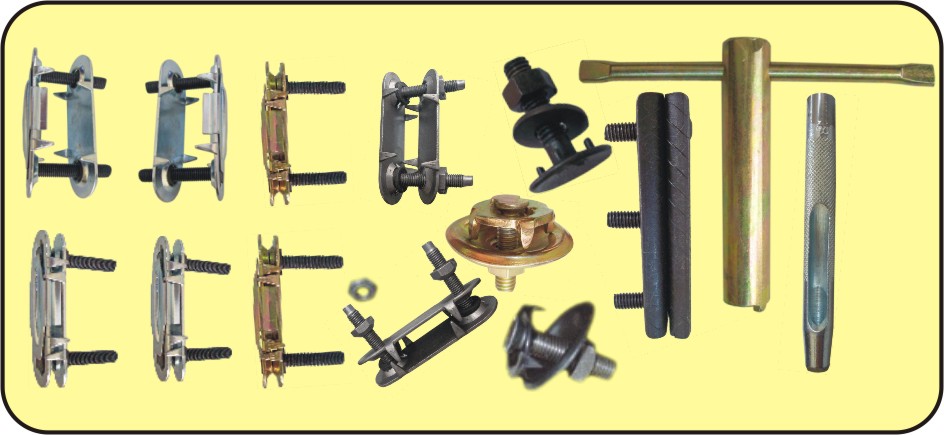

Conveyor Belt Fasteners

True, but if you mess up the splice area during the job, you need to. Clean and allow to dry properly, often forgotten. Same goes for solutions and primers: allow to dry! Also often: less use is better, so read the application manual carefully, another thing many vulcanisers don't do.

The worst thing to do is to buff the fabrics! No manufacturer will advise so. This is only done on cold vulcanising, but when buffing fabrics for hot vulcanising, you'll remove the RLF coating and actually reduce adhesion. Secondly you'll damage the fabrics reducing tensile strength.

Dear sir,

We wish to introduce ourselves as manufacturers of complete range of

Conveyor Belt Fasteners Plate Type ,Oval Belt Fasteners & Elevator Buckets

Bolt for domestic and exports markets as per IS 10288:1982 for Joining

rubber conveyor belts used in Minings,Cement,thermal,chemical

plants,Qerrying,road constructions,stone crusshing etc as follows:

1.Conveyor Belt Fastener No.1

2.Conveyor Belt Fastener No.1 1/2.

3.Conveyor Belt Fastener No. 2.

4.Conveyor Belt Fastener No 2 1/2.

5.Conveyor Belt Fastener No. 3 .

6.Oval Belt Fastener 3/8X11/2 ", 3/8X2",5/16X11/4"

7.Elevator Bucket Bolts 5/16X1"-11/4',3/8 X11/2",1/4X1"

8.L Type Mild Steel Kurling Type Fasteners

9.BOLT TIGTENING KEY

10.BOLT BREAKERS

We are ISO : 9001:2000 certified company.

We always abide contract and endeavor to offer high quality products and

reasonable price. We assure you our best of attention and services always.

Please visit our website :

www.premierudyog.org for details of our product range.

With regards.

Param vir singh.

M/s.Premier udyog,

11069/1,Street No.- 8,

Partap Nagar,Industrial Area-B,

Ludhiana-141003.

India.

Phones:91-161-2537541,3021941.

Fax: 91-161-2545377.

Cell:098140 26062.

E.Mail aram0377@gmail.com ■

aram0377@gmail.com ■

Conveyor Belt Fasteners

Dear sir,

We wish to introduce ourselves as manufacturers of complete range of

Conveyor Belt Fasteners Plate Type ,Oval Belt Fasteners & Elevator Buckets

Bolt for domestic and exports markets as per IS 10288:1982 for Joining

rubber conveyor belts used in Minings,Cement,thermal,chemical

plants,Qerrying,road constructions,stone crusshing etc as follows:

1.Conveyor Belt Fastener No.1

2.Conveyor Belt Fastener No.1 1/2.

3.Conveyor Belt Fastener No. 2.

4.Conveyor Belt Fastener No 2 1/2.

5.Conveyor Belt Fastener No. 3 .

6.Oval Belt Fastener 3/8X11/2 ", 3/8X2",5/16X11/4"

7.Elevator Bucket Bolts 5/16X1"-11/4',3/8 X11/2",1/4X1"

8.L Type Mild Steel Kurling Type Fasteners

9.BOLT TIGTENING KEY

10.BOLT BREAKERS

We are ISO : 9001:2000 certified company.

We always abide contract and endeavor to offer high quality products and

reasonable price. We assure you our best of attention and services always.

Please visit our website :

www.premierudyog.org for details of our product range.

With regards.

Param vir singh.

M/s.Premier udyog,

11069/1,Street No.- 8,

Partap Nagar,Industrial Area-B,

Ludhiana-141003.

India.

Phones:91-161-2537541,3021941.

Fax: 91-161-2545377.

Cell:098140 26062.

E.Mail aram0377@gmail.com ■

aram0377@gmail.com ■

Vulcanizability of Conveyor Belts

Dear all,

In one of the conveyors, hot vulcanizing is repeatedly failing. This is HR belt. EP 800/4 , 9/3.

When ever splicing is done, the plies are extremely look pure not having any rubber coating on them. Vulcanizers found extremely easy in making steps and removing the ply strips while splicing.

Request your valuable opinions on this.

Regards, ■