Mguray

Dear Mehdi

Please send us details and your contact adress .

Yours Sincerely,

Murat GÜRAY

KGM Aır Makina Sanayi ve Ticaret A..

stanbul- Turkey

Tel : 0090 212 537 71 13

Fax : 0090 212 538 17 98

e-mail : mguray@superonline.com

www.kgmas.com.tr please visit to our homepage ■

Re: Bucket Belt Conveyor Needed

Dear Sir :

Please visit our site :

www.medcosy.com

we can help you.

best regards

MEDCO ■

Vertical Belt Conveyor

Would you please give me your offer for a bucket belt conveyor with following specification:

1- Capacity: 350 t/h

2- Belt Width 1000 mm (Side Wall)

2- Height: 80m

3- Material density: 2.1 t/m3

4- Material: iron ore pellets, Furnace feed conveyor in steel plant

5- Temperature: ambient

remarks : bucket belt conveyor from (+20m to 20m, L=15m),H=80m,(+100,100,L=5m)

Drive units shall be hollow shaft bevel helical gearbox type with shrink disk & hydro coupling & backstop

thanks

Hi,sir,please tell me you contact information to me.We can communicate directly with email box.Mine is yang@hnpykj.com ■

Re: Bucket Belt Conveyor Needed

Dear Please take care of the following things before placing the order--

Factors that influence the capacity of an elevator are: bucket type, shape and discharge characteristics, optimum speed in relation to pulley size, shape of head and boot, material characteristics such as size, shape and density, angle of repose, coefficient of friction and terminal velocity.

The most common cause for loss of capacity in an elevator is the bucket discharge, which can be caused by the incorrect belt speed in relation to the pulley diameter, the wrong bucket for the material and the wrong head shape. Below is a table showing the three types of discharge -

Centrifugal initial discharge @ 10 o’clock- Medium to high speed for feeds and grain

Centri-gravity initial discharge @ 12 o’clock--low to medium speed--for seeds, cement.sand ect.

Gravity initial discharge @ 2 o’clock--low speed --for pellet and fragile material

Head Cover - It is necessary to design the head cover so that the material will slide smoothly along the cover to the outlet, minimizing the amount of dust created and material damage. A flat top cover design as well as any break in the head cover, such as xplosion vents or gaps, will make the material rebound onto the pulley and will result in material back legging and/or down legging.

Bucket Fill – Material enters an elevator bucket through the front and the sides.

Buckets with straight sides do not fill as well as buckets with tapered sides.

Elevator Head – To facilitate the discharge of material from the elevator head, the outlet should be large enough for the required capacity and should be at minimum 45° from the head shaft for grain and low friction particles. For other products such as meals, cement, sticky materials, and wood chips, the outlet should be at 50° to 55 deg.

Elevator Belt – Maintain proper belt tension to help avoid belt slippage on the drive pulley. A lagged head pulley will help reduce slip and wear on the belt

Elevator Boot – To ensure an efficient intake and reduce material damage and dust, place the ntake at a minimum angle of 45° from horizontal when handling grain, 50° for meals or pellets and 55° for industrial materials, to a point at least 4 inches above the line of the boot shaft so that material is directly fed into the buckets. The area of the intake should be large enough for the required volume of material. When handling grain, fitting a liner in the boot 1 to 2 inches from the lower bucket tip will increase the bucket fill, reduce grain damage and the amount of power required.

Cheers

Anil Seth

www.libranengineering.com ■

Re: Bucket Belt Conveyor Needed

Dear Sir,

Please let us have mor details.

Country of installation?

Max. Pellet Size?

Pellet Temperature?

www.aumund.com

metallurgy@aumund.de ■

Re: Bucket Belt Conveyor Needed

Factors that influence the capacity of an elevator are: bucket type, shape and discharge characteristics, optimum speed in relation to pulley size, shape of head and boot, material characteristics such as size, shape and density, angle of repose, coefficient of friction and terminal velocity.

Anil Seth

www.libranengineering.com

I thought he was asking about a sidewall elevator (Flexowell type)  ■

■

Re: Bucket Belt Conveyor Needed

Would you please give me your offer for a bucket belt conveyor with following specification:

1- Capacity: 350 t/h

2- Belt Width 1000 mm (Side Wall)

2- Height: 80m

3- Material density: 2.1 t/m3

4- Material: iron ore pellets, Furnace feed conveyor in steel plant

5- Temperature: ambient

remarks : bucket belt conveyor from (+20m to 20m, L=15m),H=80m,(+100,100,L=5m)

Drive units shall be hollow shaft bevel helical gearbox type with shrink disk & hydro coupling & backstop

thanks

Based on all the information supplied we would quote a budget price of 500,00 Euro.

A full specifiction will follow.

Best Regards

Richard Walton

WALTON PUMP SERVICES

PO BOX 1400

LONGTON, STOKE-ON-TRENT

STAFFS

ST11 9AE

U.K.

TEL: +44 1782 392547

FAX: +44 1782 392897

MOB: 07802226236

EMAIL: rw@waltonps.co.uk

WEB: www.waltonps.co.uk ■

Info

Dear,

It is a honor to represent our company IRONBUILD SYSTEMS (P) LTD. On behalf of me. We are in the field of Manufacturing of Bulk Material Handling Systems from last 30 Years.Please send me details of your requirement by mail in the following mail id.

Regards,

Pradeep Pillai

(P.R.O)

IRONBUILD SYSTEMS (P) LTD.

E-Mail : pradeeppillai04@yahoo.co.in

Ph: +91 8905980666 ■

Re: Bucket Belt Conveyor Needed

Where do you need it delivered ? ■

Bucket Elevator

Are you still looking for this or do you have it under control ■

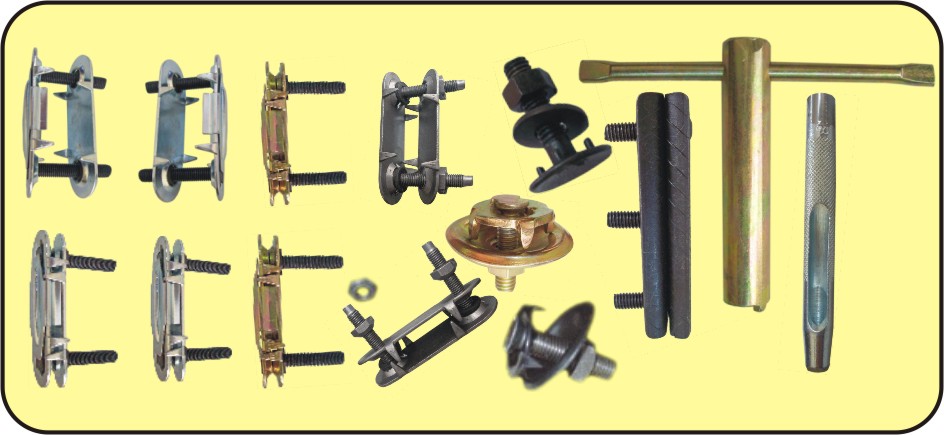

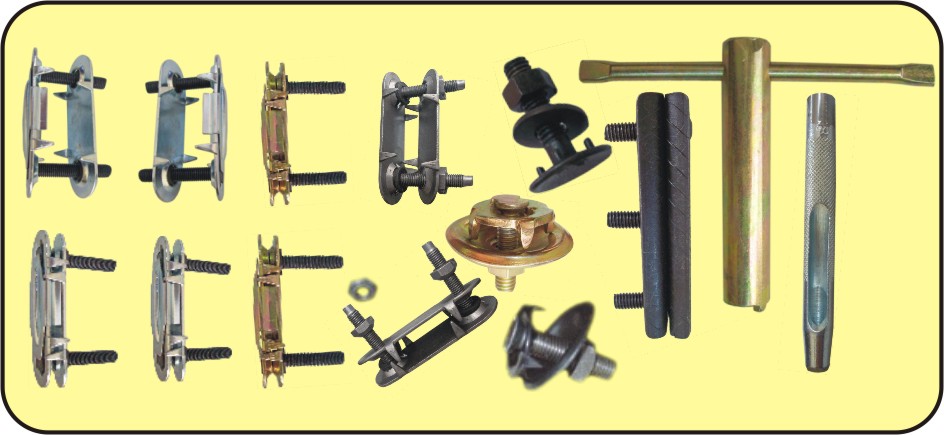

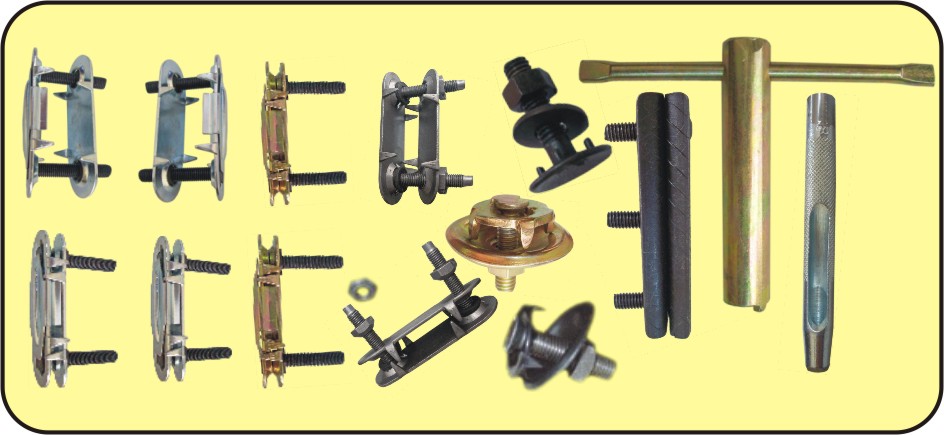

Conveyor Belt Fasteners

We wish to introduce ourselves as manufacturers of complete range of Conveyor Belt Fasteners Plate Type ,Oval Belt Fasteners & Elevator Buckets Bolt for domestic and exports markets as per IS 10288:1982 for Joining rubber conveyor belts used in Minings,Cement,thermal, chemical plants,Qerrying,road constructions,stone crusshing etc as follows:

1.Conveyor Belt Fastener No.1

2.Conveyor Belt Fastener No.1 1/2.

3.Conveyor Belt Fastener No. 2.

4.Conveyor Belt Fastener No 2 1/2.

5.Conveyor Belt Fastener No. 3 .

6.Oval Belt Fastener 3/8X11/2 ", 3/8X2",5/16X11/4"

7.Elevator Bucket Bolts 5/16X1"-11/4',3/8 X11/2",1/4X1"

8.L Type Mild Steel Kurling ! Type Fasteners

9.BOLT TIGTENING KEY

10.BOLT BREAKERS

We are ISO : 9001:2000 certified company.

We always abide contract and endeavor to offer high quality products and reasonable price. We assure you our best of attention and services always.

Please visit our website :

href="http://www.premierudyog.org" target="blank">www.premierudyog.org &

href="http://www.premierudyog.tradeindia.com" target="blank">www.premierudyog.tradeindia.com for details of our product range.

Wiyh regards.

Param vir singh.

M/s.Premier udyog,

11069/1,Street No.- 8,

Partap Nagar,Industrial Area-B,

Ludhiana-141003.

India.

Phones:91-161-2537541,3021941.

Fax: 91-161-2545377.

Cell:098140 26062.

E.Mail aram0377@gmail.com

aram0377@gmail.com

href="showthread.php?p=62496#post62496" rel="nofollow">

Would you please give me your offer for a bucket belt conveyor with following specification:

1- Capacity: 350 t/h

2- Belt Width 1000 mm (Side Wall)

2- Height: 80m

3- Material density: 2.1 t/m3

4- Material: iron ore pellets, Furnace feed conveyor in steel plant

5- Temperature: ambient

remarks : bucket belt conveyor from (+20m to 20m, L=15m),H=80m,(+100,100,L=5m)

Drive units shall be hollow shaft bevel helical gearbox type with shrink disk & hydro coupling & backstop

thanks

Attachments

■

Bucket Belt Conveyor Needed

Dear Members,

Would you please give me your offer for a bucket belt conveyor with following specification:

1- Capacity: 350 t/h

2- Belt Width 1000 mm (Side Wall)

2- Height: 80m

3- Material density: 2.1 t/m3

4- Material: iron ore pellets, Furnace feed conveyor in steel plant

5- Temperature: ambient

remarks : bucket belt conveyor from (+20m to 20m, L=15m),H=80m,(+100,100,L=5m)

Drive units shall be hollow shaft bevel helical gearbox type with shrink disk & hydro coupling & backstop

thanks ■