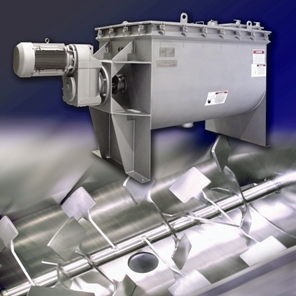

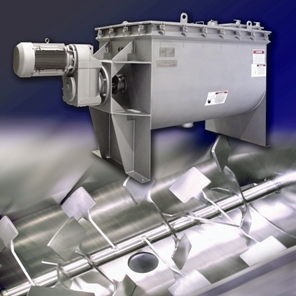

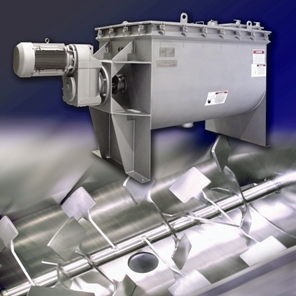

Fluidizing Paddle Blender

NEW! OptimaBlend™ Fluidizing Paddle Blender

American Process Systems, Member Eirich Group, is pleased to introduce THE NEXT GENERATION IN MIXING! As the newest addition to our complete line of mixing equipment, the OptimaBlend™ Fluidizing Paddle Blender is a balance of mixing speed and efficiency with low equipment cost and consumed power. Traditional ribbon blender applications will benefit from increased capacity in the same space. Difficult & diverse ingredients can now be mixed quickly with high efficiency.

The OptimaBlend™ offers:

• Mixes five times faster than a ribbon blender

• High mix efficiencies with low co-efficient of variation (CV’S)

• Homogenous mixes independent of large range of particle size, shape or density

• High throughput rates with low horsepower

• Fluidizes powders quickly and efficiently

• Less degradation than ribbon blenders

• Efficient liquid addition

• Easy clean-out

• Low heat generated due to friction

Units are available in carbon steel, stainless steel and sanitary construction for a wide variety of solids to solid and solids to liquid blending applications.

For more information, please visit:

href="https://edir.bulk-online.com/profile/10354-american-process-systems-eirich-machines.htm" target="blank">https://edir.bulk-online.com/profile...h-machines.htm

href="http://www.google.com/search?hl=de&client=safari&rls=de-de&q=Eirich+site%3Abulk-online.com&btnG=Suche&lr=" target="blank">http://www.google.com/search?hl=de&c...btnG=Suche&lr=

View this video:

href="http://media.bulk-online.com/video/52/OptimaBlend™-Fluidizing-Paddle-Blender" target="blank">http://media.bulk-online.com/video/5...Paddle-Blender

Attachments

■

Re: Eirich Machines & Aps

DRYING & EVAPORATION EQUIPMENT

American Process Systems - Member Eirich Group, manufacturers a complete range of cylindrical plow blender dryers and vacuum dryers.

These dryers use a combination of enhanced mixing technology to fluidize the ingredients exposing more of the particles to the drying effects of heat and vacuum, indirect heating via ASME jackets designed for hot water, steam, hot oil or vapor, and vacuum in a vacuum dryer to lower the flash point of the liquid water or solvent allowing lower temperature drying and processing which is important for heat sensitive ingredients and shortens the drying time.

Enhanced mixing technology is achieved with agitators of defined geometry at high rotational speeds that fluidize ingredients allowing particles of vastly differing size, shape and density to be precisely and efficiently mixed.

Vessels are capable of internal working temperatures to 700°F and internal pressures to 700 PSI and full vacuum. Materials of construction include stainless steel, corrosion resistant Duplex stainless steels, Hastelloy and Inconel and abrasion resistant steels. Levels of polish available from industrial to sanitary food and pharmaceutical to USDA Dairy.

Let us design a system for you tailored to your application requirements.

For more information, please visit:

href="https://edir.bulk-online.com/profile/10354-american-process-systems-eirich-machines.htm" target="blank">https://edir.bulk-online.com/profile...h-machines.htm

href="http://www.google.com/search?hl=de&client=safari&rls=de-de&q=Eirich+site%3Abulk-online.com&btnG=Suche&lr=" target="blank">http://www.google.com/search?hl=de&c...btnG=Suche&lr=

View this video:

href="http://media.bulk-online.com/video/52/OptimaBlend™-Fluidizing-Paddle-Blender" target="blank">http://media.bulk-online.com/video/5...Paddle-Blender

CPB-200 Paddle Dryer with heat traced dust collector

Attachments

cpb-200 paddle dryer with heat traced dust collect (JPG)

■

Eirich Machines & APS

American Process Systems - Member EIRICH GROUP

Eirich Machines & American Process Systems, as leading manufacturers of high quality mixers, dryers, reactors, and ancillary equipment, offer customers an unequalled base of experience, affordable quality, and innovative technology. Together, the two divisions offer the most comprehensive line of mixing equipment available.

American Process Systems’, Member Eirich Group, entire line of equipment, including USDA design and ASME certified pressure vessels, is manufactured in our modern facility in Gurnee, Illinois which includes a test facility. A full line of test equipment allows for pre-sale testing in our lab or the customer’s own plant.

Application expertise and unparalleled design flexibility make Eirich Machines the suitable choice to meet any process requirement.

APS/Eirich headquarters in Gurnee, IL

For further information on our capabilities, please contact us at:

P: 847-336-2444

F: 847-336-0914

Or, visit our website at www.eirichusa.com to view both of our product lines.

For more information, please visit:

https://edir.bulk-online.com/profile...h-machines.htm

http://www.google.com/search?hl=de&c...btnG=Suche&lr=

View this video:

http://media.bulk-online.com/video/5...Paddle-Blender ■