Jvi Vibratory Equipment Inc.

Fields of Activity

JVI's custom-engineered solutions are installed in factories and plants around the world.

We specialize in the manufacture of:

Electromechanical Feeders

Electromagnetic Feeders

Brute Force Feeders

Single Mass Feeders

Precision Dosing Feeders

Bin Dischargers with Integrated Chutework Packages

Tube Conveyors

Screeners / Screens

Separators & Classifiers

Railcar and Truck Dump Discharge Station Feed Out Systems

Foundry Feeders

Spiral Elevators

All JVI equipment is custom engineered from proven design standards to fit the application.

Industries Served:

Cement

Chemicals

Coal

Coke

Fertilizers

Food

Foundry

Glass

Grains

Gravel

Gypsum

Limestone

Metals

Mining

Minerals

Ores

Pharmaceutical

Plastics

Recycling

Rock & Dirt

Rubber

Steel

Textiles

Wood

Typical Applications

Align

Batch

Classify

Convey

Discharge

Distribute

Dose

Elevate

Feed

Meter

Package

Proportion

Recycle

Scalp

Screen

Separate

Sort

Spread

Transport

Some of the Materials Handled by JVI Equipment

Wrapped Bubble Gum

Sunflower Seeds

Elbow Marconi

Coal

Carbon Black

Quenched Slag

Grass Seed

Fertilizer

Aluminum Dross

Pelletized Borate

Silica Sand

Parts -Drill Bits

Flower Seeds

Corn

Iron Carbide

Pet Coke

Cupola Charging

Metal Chips

Ferrite Titanium

Lead Oxide

Metallic Magnesium

Plastic Pellets

Steel Slag

Clay (Cooler)

Flour & Pasta

Dolomite

Pig Iron

Popcorn

Coffee Beans

Pinto Beans

Cement Powder

Moth Balls

Salt Fines

Dog Food

Portable Corn Flake

Nylon Pellets

Cocoa Beans

Wet Sugar

Cullet / Crushed Glass

Cereal Pellets

Pork Rinds

Cocoa Beans

LDPE, HDPE Pellets

Waste, Recycled

Ice Cream Pints

Wood, Chips

Cane Sugar

Animal Feed

PVC Pellets

Pigment Powders

Chocolate Candies

Mixed Nuts

For more information, please visit:

href="https://edir.bulk-online.com/profile/1825-jvi-vibratory-equipment.htm" target="blank">https://edir.bulk-online.com/profile...-equipment.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=jvi+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

Attachments

■

Jvi Vibratory Equipment Inc.

JVI CASE HISTORY

Material Handling Feeders

The JVI Electromechanical feeder is effective in a variety of dry bulk material handling applications. Each JVI vibratory feeder is engineered to the exact application requirements. This volumetric feeder has an inherent ability to work reliably regardless of load size or material characteristics. It works particularly well with wet, sticky, frozen coal and other aggregates and minerals that are commonly exposed to the environment.

High capacity, short distance conveying for:

Storage discharge

Stockpile reclaim

Railcar unloading

Crusher feeding

Spreading

Batching

For Bin and Hopper Discharge:

Shown here is the Integrated Chutework Package for bin and hopper discharge feeders. This complete package includes the feeder, the chutework and the supports in one piece of equipment that bolts directly to the hopper outlet. It is engineered to fit your hopper outlet. This unique design ensures proper clearances, eliminates cable supports, and reduces installation costs.

Photo:

An integrated chutework package feeder

For more information, please visit:

href="https://edir.bulk-online.com/profile/1825-jvi-vibratory-equipment.htm" target="blank">https://edir.bulk-online.com/profile...-equipment.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=jvi+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

Attachments

■

Jvi Vibratory Equipment Inc.

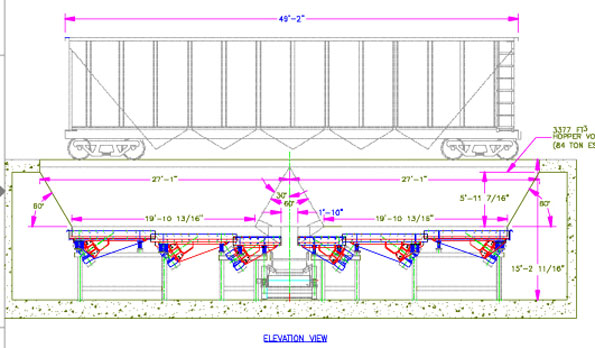

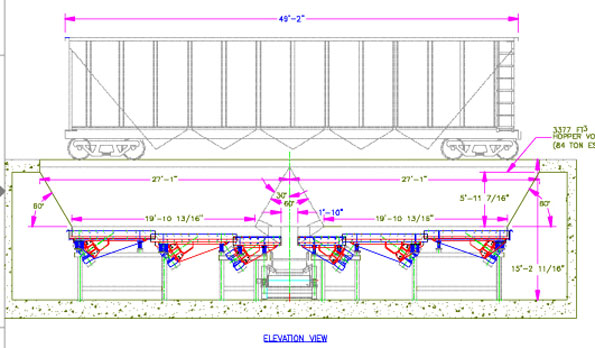

The TITAN System for Long Hopper Discharge

The TITAN is a vibratory feeder discharge system designed for discharging large hoppers that have long, narrow discharge openings with high material head loads. It is ideal under truck dump stations, and rail or track hoppers that discharge onto conveyor belts.

Why is it better than Belt and Apron Feeders?

Compaction is a common problem when using belt or apron feeders due to their inherently poor design for this application. Unlike belt or apron feeders, material in the TITAN system is discharged from the front to the back so only free flowing material is being moved. Using this principle, compaction of the static material in the hopper is avoided.

BENEFITS OF THE TITAN SYSTEM

Less Wear and Maintenance - The low average system duty and distributed utilization of the multiple vibratory feeders (which have inherently low maintenance in themselves) offer substantial reduction in maintenance costs and downtime in comparison to belt and apron feeders.

Low Energy Consumption - Because the whole feeding unit is not always in operation at the same time -each feeder works independently- the power requirements diminish when compared to belt and apron feeders.

Minimal Vertical Head Room - The TITAN System, with its small work-space requirements, allows for long slotted narrow hoppers to be designed in work envelopes where it might otherwise not be possible to consider belt feeders or apron feeders.

High Storage Capacities - By incorporating long slotted hoppers and the TITAN system by JVI, a plant can store maximum material volume in smaller work envelopes at reduced installation costs.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1825-jvi-vibratory-equipment.htm" target="blank">https://edir.bulk-online.com/profile...-equipment.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=jvi+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

Attachments

■

Jvi Vibratory Equipment Inc.

Batching and Dosing Feeders

A light duty, vibratory dosing feeder by JVI is ideal for batching, weighing and dosing applications where small volumes are conveyed and micro-fine, accurate control is required for the feed rate. The feeders are engineered to the individual application requirements. All dosing machine models can be supplied in accordance with FDA or USDA specifications for use in the food, drug and cosmetic industries.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1825-jvi-vibratory-equipment.htm" target="blank">https://edir.bulk-online.com/profile...-equipment.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=jvi+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

Attachments

■

Jvi Vibratory Equipment Inc.

Available with many options such as the integrated hopper package or various stainless steel finishes, the DPF feeder is very versatile. The DPF feeder is excellent for use in light to medium duty feeding applications for food, chemical, pharmaceutical and other processing industries. The 0 to 100 % adjustable feed rate controls make the JVI DPF model feeder a precise batching feeder for packaging applications.

Several electromagnetic drive models are available to satisfy a broad range of feeder sizes and possibilities. All 60Hz drives are available for 110V or 220V service. The DPF's drive has instant on/off capability, fine rate adjustment, and requires no maintenance. Materials of construction for the feeder trough include Stainless Steel or Mild Steel. The hopper of the DPFH is designed with 75 degree walls to promote material flow at a constant rate and eliminate product bridging at the discharge. The feeder trough can be designed with vertical or horizontal discharge and a closed or open trough. The material bed depth is also adjustable to accommodate materials and capacity ranges.

For more information, please visit:

href="https://edir.bulk-online.com/profile/1825-jvi-vibratory-equipment.htm" target="blank">https://edir.bulk-online.com/profile...-equipment.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=jvi+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

Attachments

■

Jvi Vibratory Equipment Inc.

Vibratory Screens

JVI manufactures many styles of light, medium, and heavy duty vibratory screens. JVI offers both linear and circular motion screen models, as well as banana screens. JVI screens are customized to the application requirements- this means they are "engineered to order". Manufacturing customized vibratory screens from proven design standards is a cost effective approach to application specific requirements that cannot be met by other 'off-the-shelf" solutions.

Benefits of JVI Screens

Low maintenance.

Repeatable performance.

Excellent control packages available.

World-class JVI electromechanical or exciter drives.

Designs available for capacities up to 2500 TPH.

Simple rugged design

For more information, please visit:

href="https://edir.bulk-online.com/profile/1825-jvi-vibratory-equipment.htm" target="blank">https://edir.bulk-online.com/profile...-equipment.htm

href="http://www.google.com/search?client=safari&rls=de-de&q=jvi+site:bulk-online.com&ie=UTF-8&oe=UTF-8" target="blank">http://www.google.com/search?client=...UTF-8&oe=UTF-8

Attachments

■

JVI Vibratory Equipment Inc.

JVI VIBRATORY EQUIPMENT INC.

Officers:

Mark Neundorfer, President and CEO

Rob Bishop, Vice President of Sales & Marketing

Danny Guerra, Vice President of Engineering

Russell Broussard, Sales Engineer

Description:

Established in the 1980s, JVI has made a niche for themselves by engineering innovative, application specific vibratory equipment for the material handling industry. JVI specializes in the manufacture of vibratory feeders, screens, conveyors and spiral elevators with both electromechanical and electromagnetic models. JVI focuses on providing brute force, volumetric, single or dual mass machines. All JVI equipment is custom engineered from proven design standards to fit the application.

Markets Served:

JVI has engineered custom vibratory equipment for a broad range of industries, including aggregates & mining, foundry, steel, scrap & recycling, power & coal, chemicals, food & pharmaceuticals, and even textiles and glass.

Research & Development:

JVI strives to develop new vibratory technology for dry bulk material handling solutions that encompass the broad range of markets served by JVI. JVI engineers and technicians focus on enhancing existing vibratory equipment technology as well as developing innovative designs that provide significant benefits in the field. These enhancements and innovative designs are developed through in house material and equipment testing, 3D modeling, finite element analysis (FEA) and decades of field experience and material handling expertise.

Technologies:

Using proven design standards, All JVI equipment is custom engineered to fit the application. In house material and equipment testing, 3D modeling, finite element analysis (FEA) and decades of field experience and material handling expertise make it possible for JVI to achieve the advancements in technology to meet the growing and evolving needs of the material handling industry to the benefit of every JVI customer.

Facilities:

JVI envelopes a 12000 square feet corporate facility in Houston, TX that encloses Administration, Engineering and Manufacturing processes as well as the Research and Testing Lab. Representative offices are located in major U.S. cities and in Canada. JVI also has a partner in Europe, AviTeq.

For more information, please visit:

https://edir.bulk-online.com/profile...-equipment.htm

http://www.google.com/search?client=...UTF-8&oe=UTF-8

Photo:

Corporate Head Quarters in Houston, TX

Attachments

1_jvi_1 (JPG)

■