Kalenborn Wear Protection (Continued)

For more information, please visit:

href="https://edir.bulk-online.com/profile/8077-kalenborn-kalprotect.htm" target="blank">https://edir.bulk-online.com/profile...kalprotect.htm

href="http://www.google.com/search?hl=de&client=safari&rls=de-de&q=kalenborn+site%3Abulk-online.com&btnG=Suche&lr=" target="blank">http://www.google.com/search?hl=de&c...btnG=Suche&lr=

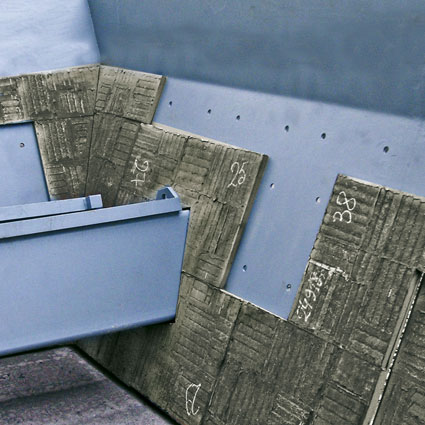

Photo 2:

Simple replacement thanks to mechanical fastening of

KERAFLEX-WRM elements in case of heavy abrasion and impact loads

Attachments

■

Kalenborn Wear Protection (Continued)

For more information, please visit:

href="https://edir.bulk-online.com/profile/8077-kalenborn-kalprotect.htm" target="blank">https://edir.bulk-online.com/profile...kalprotect.htm

href="http://www.google.com/search?hl=de&client=safari&rls=de-de&q=kalenborn+site%3Abulk-online.com&btnG=Suche&lr=" target="blank">http://www.google.com/search?hl=de&c...btnG=Suche&lr=

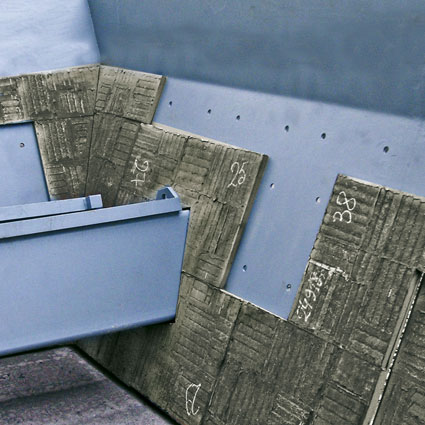

Photo 3:

KALPOXY epoxy bonded hard compound combines

high abrasion resistance with easy working, which

makes it excellently suited also as repair compound

Attachments

■

Kalenborn Wear Protection (Continued)

For more information, please visit:

href="https://edir.bulk-online.com/profile/8077-kalenborn-kalprotect.htm" target="blank">https://edir.bulk-online.com/profile...kalprotect.htm

href="http://www.google.com/search?hl=de&client=safari&rls=de-de&q=kalenborn+site%3Abulk-online.com&btnG=Suche&lr=" target="blank">http://www.google.com/search?hl=de&c...btnG=Suche&lr=

Photo 4:

KALCRET sprayed-on compound allows large surfaces to be lined

in a minimum of time. It may be applied by spraying horizontally,

vertically or even overhead without any problems

Attachments

■

Kalenborn Wear Protection

Systems Secure the Lead of Kalenborn Wear Protection Technology

Kalenborn supply wear protection materials from a single source. The materials include ABRESIST fused cast basalt, KALCOR zirconium corundum, KALOCER high alumina ceramics, KALMETALL hard metals, KALCRET hard compound, etc. The materials are not only offered by Kalenborn but mostly produced in their own workshops. This ensures high product quality, optimal delivery times and a good price / performance ratio.

Now Kalenborn go even one step further - they supply complete wear protection systems. These systems enable optimized solutions even of complex wear problems. They reflect the

state-of-art practiced by Kalenborn and the lead of Kalenborn in wear protection technology.

Typical Kalenborn wear protection systems are the following:

KALFLEX Flexible Pipe Bends

KALFLEX consists of abrasion resistant segments that fit into each other. This results in variable radii and angles of the pipe components.

The segments are enclosed in a rubber jacket containing a fabric insert, producing the needed stability and tightness. Available sizes range from 20 to 150 mm ID, covering pipe sizes used

in many pneumatic conveying systems.

The wear resistant segments have mostly been produced from KALMETALL-C hard casting. In case of extreme sliding abrasion the segments can be made of KALOCER high alumina ceramics.

The advantages of KALFLEX result from its flexible adaptability to pipe systems. KALFLEX is extremely abrasion resistant, easy to install and well suited for preventive storekeeping. In addition,

KALFLEX pipe bends are used to advantage as pipe transitions, expansion joints or as flexible connections between two fixed points if a rigid joint involves the risk of pipe fractures and, consequently, that of undesired plant stops.

KERAFLEX Withstanding Intense Impact and Wear Stress

KERAFLEX are hard materials like KALOCER high alumina ceramics or KALMETALL-W hard overlay welded plates vulcanized in rubber. The elements are used, in particular, whenever heavy abrasion occurs combined with high impact loads.

KERAFLEX elements are characterized by a hard and wear resistant surface. They are impact resistant thanks to an individually strong rubber layer and optimal system vulcanization. They are easily and reliably fastened by mechanical means and/or glued. The elements can be replaced without any difficulty. The system allows optimal adaptation to varying sizes, thickness and design. On top of that the system offers efficient sound insulation.

KERAFLEX is typically applied in practically all fields of the basic industry, i.e. wherever bulk materials are conveyed, in particular impact surfaces in bunkers, belt transfer points and inlet chutes.

KALCRET and KALPOXY Hard Compounds

For many years Kalenborn have offered a comprehensive range of hard compounds. Whereas KALCRET offered so far covers cement bonded materials excellently suited for application to large surfaces, Kalenborn have now included KALPOXY in their product array, an epoxy bonded hard compound that combines high abrasion resistance with easy workability.

The selective use of mineral hard materials (corundum) combined with the heavy duty epoxy resin matrix enable KALPOXY systems of varying layer thickness thereby ensuring an efficient and simple protection of locations that are subject to particular stress.

KALPOXY hardens at room temperatures of 20° C / 68° F in a short time. The maximum application temperature is 80° C / 176° F. The 2-component system is offered at pre-dosed packages to warrant easy handling.

KALPOXY has to be compared with the wide range of cement bonded KALCRET hard compounds which have excellently stood the test for many years. KALCRET is offered at different working modes. It can be trowelled, cast and sprayed-on.

KALCRET sprayed-on compound allows large surfaces to be lined in a minimum of time. It may be applied by spraying horizontally, vertically or even overhead without any problems. The high material compaction ensures excellent abrasion resistance.

Powtech 2008 in Nuremberg

Numerous factors decide on whether and if so, which Kalenborn wear protection system will be chosen for solving a particular wear problem. The Kalenborn experts give comprehensive advice and will submit selective proposals after having familiarized themselves with the specific requirements.

Kalenborn offer a welcome chance for meetings and extensive discussion of all queries related with wear protection on the occasion of this year’s Powtech to be held in Nuremberg from September 30 to October 2, 2008.

For more information, please visit:

https://edir.bulk-online.com/profile...kalprotect.htm

http://www.google.com/search?hl=de&c...btnG=Suche&lr=

Photo 1:

KALFLEX enables a flexible connection between two

fixed points if a rigid joint involves the risk of pipe

fractures and, consequently, that of undesired plant stops

Attachments

bild_1_kalflex (JPG)

■