Re: Apron Feeder Skirting

Apron feeders are contentious beasts which rely on brute force. You should have plenty of spare power if you hav material which gets under the 30-5-mm gap ( why the difference?).

You can safely extend the skirt to close the gap.

Alternatively you can bolt angle cleats onto the pan edges, use slotted holes of course, to provide an ovelapping seal which will not, itself, wear because it is moving with the material. Too easy? ■

John Gateley johngateley@hotmail.com www.the-credible-bulk.com

Photo

Angle cleats sound like a feasible prospect.

I hope maybe this photo helps with visualising the issue. Some of the plates/bars do seem to look a bit deformed, which is the likely cause of the variation in the gaps heights.

Attachments

■

Re: Apron Feeder Skirting

If you decide to extend the skirt down closer to the pans, make sure the gap increases ever so slightly in the direction of travel. Otherwise you may need a lot more power than you think trying to overcome wedged in material. ■

Apron Feeder Skirting

Hi Nishand

Several of our clients have gone the route of installing a wide spillage conveyor under the our apron feeders. This is to collect spillage and carry it to the apron feeder head discharge chute.

Regards

John Cripps

Osborn Engineered Products

South Africa

www.osborn.co.za ■

Re: Apron Feeder Skirting

Hi Nishant

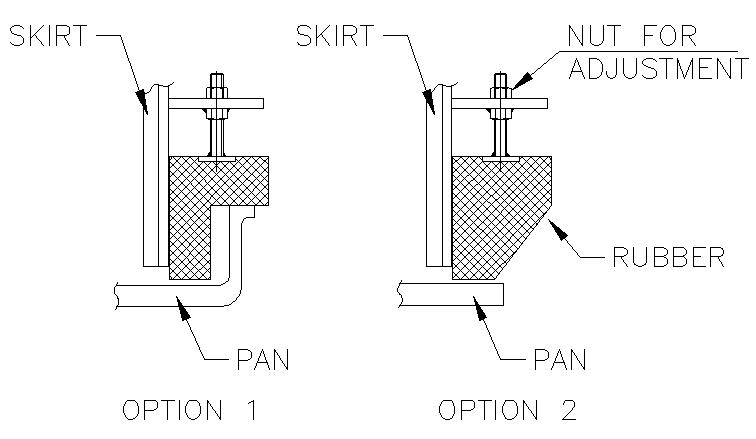

Usually in cases like this, you can use an adjustable rubber for sealing, as shown in the attached file.

Regards.

Castro

Metso Minerals Brazil

href="http://www.metsominerals.com" target="blank">www.metsominerals.com

Metso Minerals is a global supplier of solutions, equipment and services for rock and minerals processing. Its expertise covers the production of aggregates, the processing of ores and industrial minerals, as well as construction and metal recycling. Metso Minerals is a business area of Metso Corporation, a global engineering and technology corporation with 2007 net sales of approximately EUR 6 billion. Its more than 27 000 employees in more than 50 countries serve customers in the pulp and paper industry, rock and minerals processing, the energy industry and selected other industries.

Attachments

■

Re: Apron Feeder Skirting

Thanks for the information.

The rubber backing idea seems worthwhile.

There is already a spillage conveyor under the apron feeder, but they are hoping to reducing the amount of material that falls through to it in the first place. ■

Re: Apron Feeder Skirting

Hi Nishant,

I work at EMO in Rotterdam as technical inspector

the guy from Metso Brasil had a good solution

We use there "wear-bars" WB100 x 50 for stopping the spillage

We fixed the bars to an angle iron for quick changing and the are about 10 mm from the plates of the feeder.

greetings

harry ■

Apron Feeder Skirting

Dear all

We have an apron feeder being fed via a hopper. There is currently a gap of approx 30-50mm between the top of the apron feeder and bottom of the skirt/hopper, which is causing material to fall through.

We are hoping to eliminate material leakage by extending the skirting or installing seals at this gap. I would like to know whether such sealing is common (or even available), such that it does not affect the power demand? I have already contacted manufacturers for some skirting information, and am awaiting some information.

Short of widening the opening width of the hopper such that the skirting sits along the outside edge of the apron feeder (due to time and cost constraints), I would appreciate any feedback on whether anyone has come across something similar. ■