Hosokawa Alpine Aktiengesellschaft

(continued)

Company History

The company can trace its roots back to Otto Holzhäuer, who opened a small mechanical workshop for tool manufacture at Oberen Graben 6 in Augsburg in 1886. Around the turn of the century, his premises in the centre of the city became too small, prompting him in 1898 to buy a plot of land on Augsburger Strasse in Göggingen, where, surrounded by meadows and fields, he had a "residence, factory building with office and courtyard" built. These buildings are still standing today on the company premises of Hosokawa Alpine, an area which extends between Gögginger Strasse and Peter-Dörfler-Strasse.

In early 1900, Hugo Sachs – a captain of industry in Munich – acquired an interest in the company, which with effect from 1 September 1911, changed its legal form to an incorporated firm and traded henceforth under the name Alpine Maschinenfabrik GmbH. In 1916, Sachs became the sole owner of the company and his nephew, Theodore Sachs, became a member of the managing board. On 30 September 1938, Hugo and Theodore Sachs sold the Alpine AG to Mathias Fränkl, the owner and chief executive of MAPAG (Maschinenfabrik Augsburg-Plattling AG).

After the end of the Second World War, the activities of Dr.-Ing. Hans Rumpf in his capacity as chairman of the executive board were of decisive importance for the recovery of Alpine. In 1956, he was offered a professorship at the Karlsruhe University of Technology for the Department of Mechanical and Process Engineering, where he laid the foundation stone for the international reputation of the Karlsruhe Institute on this sector.

After Dr. Rumpf left, the company was taken over first by Kurt Bösch in 1972 and subsequently by his son, Thomas Bösch, up until 1987.

After being taken over by the Hosokawa Micron Group with headquarters in Osaka, Japan, the company changed its name once again in 1987 to Hosokawa Alpine.

The Group, which is headed by Mr. Masuo Hosokawa in his capacity as chairman and president, is the leader on the global market of processing fine powders and counts among the leading companies on the sectors of systems for bakery products and confectionery and film extrusion systems.

In 1992, Achim Vogel was appointed member of the executive board of Hosokawa Alpine Aktiengesellschaft and was elected chief executive officer by the supervisory board in 1995. He simultaneously became a member of the company management of Hosokawa Bepex, Leingarten, and Hosokawa Powders GmbH in Cologne.

Within the Hosokawa Micron Group, Mr. Vogel was responsible as the deputy COO (Chief Operations Officer) for the European Hosokawa companies. Dipl.-Ing. Achim Vogel retired from the company on 30 September 2006.

The supervisory board elected Dipl.-Ing. Peter Krieg, the long-standing director of the Minerals & Metals Division, as the new chief executive officer with effect from 1 May 2006. This measure was taken as part of the long-planned generation change within the company management and will contribute towards the continuity and strengthening of the company for the challenges of the future.

The new executive board of Hosokawa Alpine comprises three members:

Dipl.-Ing. Peter Krieg, chairman of the executive board and responsible for the blown film processing division plus the marketing and manufacturing departments, Georg Ringmayr, MBA, responsible for the financial, controlling and personnel departments, and Dipl.-Ing. Bertram Brenner, responsible for the powder and particle processing division.

Hosokawa Alpine Augsburg, with its branch office in Cologne and the two subsidiaries, one in Leingarten close to Heilbronn and the other also in Cologne, today employs a total of 700 staff and 65 trainees in Germany, and contributes approx. 135 million € p.a. to the total turnover of the international Hosokawa Micron Group.

(continued)

Photo:

Dipl.-Ing. Peter Krieg, chairman of the executive board since May 2006

Attachments

■

Hosokawa Alpine Aktiengesellschaft

(continued)

Grinding and Classifying Systems

The founding year of Alpine – 1898 – was very important in that with the design and construction of the "Triumph" universal mill, Holzhäuer's company established itself on the sector of fine size reduction, the sector that is still today one of the core competences of the company.

During the course of the company history, mills were developed for ever finer powders and today, powder particles with a diameter of between 1 and 2 µm are produced with Hosokawa Alpine systems. As a means of comparison: a human hair has a diameter of approx. 100 µm. At the same time as the mills, the company also engineered and built air classifiers to separate coarse and fine particles. In the process, Alpine's engineers achieved something of a world record in 1967: for the first time, a cut point of 1 micron – which corresponds to 1/1000 mm – was achieved.

Today, Hosokawa Alpine develops new technologies for particle design on a nano-scale in collaboration with the Hosokawa Powder Technology Research Institute in Japan ( HPTRI ), an R&D facility of the Hosokawa Group established in 2002 with 75 employees. The objective for specific applications is not only to manufacture the finest possible particles, but also to supply these particles with certain properties. These properties can be of a mechanical, optical, electrical or chemical nature. New and interesting possibilities have opened up, especially on the sectors of pharmaceutics, cosmetics, battery/storage battery manufacture, metallurgy and in the development of fuel cells.

(continued)

Photo:

Classifying system to manufacture toner

Attachments

■

Hosokawa Alpine Aktiengesellschaft

(continued)

From Toner to Artificial Hip Joints

Fine powders are required in just about every branch of industry. In the chemical industry, for example, for fine-grade chemicals, toner, paints, abrasives, plastics, synthetic resins and wax, or in the pharmaceutical industry for pharmaceutical active substances, dental compounds, vitamins and medicinal herbs, or in the food industry for proteins, carbohydrates, roughage and dairy products.

The applications are so numerous that powders can be found in almost every product of our daily life that just might have been manufactured with Hosokawa Alpine grinding and classifying systems.

The powders are either the raw material for an end product, for example quartz powder for glass, mineral powders for tiles, cacao powder for chocolate, and wood dust for particle boards, or they serve as a filler, as for example limestone powder in plastic products, carbon black in tyres, plastic powder in coatings or limestone and cellulose in paper.

(continued)

Photo:

Pigments that bring colour to plastics, paper or textiles are ground with Alpine machines

Attachments

■

Hosokawa Alpine Aktiengesellschaft

(continued)

Wide Range of Products and Services

Hosokawa Alpine stands for competence in all areas of size reduction technology. The many years of close cooperation between the customers' R&D departments and the Hosokawa Alpine engineers have made the company into a leading specialist on the global market for powder technology. And to ensure that the user always finds a competent contact at Hosokawa Alpine, regardless of the user's branch of industry, the company's Powder and Particle Processing business segment is subdivided into five different divisions: Pharma & Food, Chemicals, Minerals & Metals, Recycling and Granulators, and Service.

The machine programme comprises the Alpine laboratory air jet sieve 200 LS-N, the granulators Rotoplex RO, Compact Line CL, Polymer Line PL, Eco Line EL and the fine cutting mills AFS, the hammer mills Ha and crushers DB and SB, the Mikro Pulverizer MP, the mechanical fine impact mills UPZ, the long gap mills LGM, the Contraplex pin mills CW, the classifier mills Powderplex APP, and Zirkoplex ZPS, the Mikro ACM classifier mills, the spiral jet mills Aeroplex AS, the fluidised bed opposed jet mills AFG, TFG and TTG, the table roller mills AWM, the ball mills Super-Orion SO and the agitated ball mills ATR. Air classifiers like the Multiplex zigzag classifiers MZM and MZF, the Ventoplex air classifiers V, the Micron air classifiers MS, the Stratoplex air classifiers ASP, the Turboplex ultrafine classifiers ATP, the Turbo Twin Classifiers TTC and the Toner classifiers TSP and TTSP. For wet processing Alpine offers the agitated ball mills AHM and ANR, the Powerpaint DPP and the Hydroplex AHP classifier. For nanotechnology and particle design Alpine offers for coating the systems AMS and Nobilta, for dispersion and micro-mixing the systems Nobilta and Nanocular, for particle rounding the systems AMS and Faculty, for agglomeration the system Agglomaster and for MCB mechano-chemical-bonding the system Nanocular and for mechanofusion the system AMS.

The more demanding the problem specification, the more the customers profit from the comprehensive services offered by the company, which range from advice regarding trials, engineering, complete process automation, documentation, manufacturing, project planning and supervision to commissioning and operator training on the customer's premises.

Hosokawa Alpine's application testing centre is equipped with more than 60 machines and systems over a floor space of approx. 3000 m3, thus offering unique possibilities of performing trials aimed at determining the ideal system design and layout plus the process-technological guaranteed parameters, both on a laboratory and a production scale.

Film Extrusion Business Segment

Film blowing systems for one- and multi-layer film have also been manufactured at Hosokawa Alpine since 1955. These systems are employed by our customers to produce 1-, 3-, 5- or 7-layer film, which is then used as packaging for food, building materials, pharmaceutical products, electronic components and also as barrier film for plasma display screens or in the manufacture of carrier bags, gift wrap and labels.

(continued)

Photo:

Alpine extrusion systems are used, for example,

to manufacture cling film

Attachments

■

Hosokawa Alpine Aktiengesellschaft

(continued)

The Augsburg Location

Throughout the over 100-year company history, the company management has always acknowledged its commitment to Augsburg as a business location, because top-quality products call for sound know-how in development, design & engineering, manufacture and assembly. And this is synonymous with the competence that results from the training, knowledge, experience and last but not least the motivation of the staff. The setting of the company headquarters in Augsburg has always fulfilled these requirements in the best possible way. And the company will continue to be successful in the future, provided that the customers continue to make a profit with the machines from Hosokawa Alpine. This constitutes the type of challenge which can only be mastered by continuous refinement of our products, optimisation of the manufacturing processes and ongoing qualification of the staff.

Investments in the Augsburg Location

The economic success of the past years and the good orders situation have strengthened the company's resolve to continue investing in Augsburg as a business location. The current focus concentrates thereby on construction of new production and assembly facilities which better meet the demands set a modern mechanical engineering company. Investments to the tune of 20 million € are planned. From spring 2007 onwards, a new production hall measuring 6,500 m effective area will be constructed during the first building stage with a project volume of 9.5 million €. Completion is scheduled for spring 2008 – an ambitious objective, if one considers that production will continue without interruption.

The Staff

After the Second World War, the company employed a total of 200 staff. Thanks to revolutionary developments made by Alpine engineers on the sector of grinding and classifying systems in the 1960s and 1970s, the number of employees grew to 500; a number which Hosokawa Alpine has been able to maintain to this day, and a development which sets the company off very positively against other Augsburg companies. Of the current 540 employees in Augsburg, 40% are in sales and engineering, another 35% in production, 10% in research and development, 5% in administration and 10% are trainees.

Many of the staff live in South Augsburg or in Göggingen. A total of 70% of the employees who work in the production department started their career as a trainee at Hosokawa Alpine. No wonder that there are some families who have family members spread over 3 generations working in the company.

(continued)

Photo:

Alpine company premises with the new production

halls included in building stages 1 and 2 on the

right-hand side of the diagram

Attachments

■

Hosokawa Alpine Aktiengesellschaft

(continued)

On-the-job training

Whoever wants to shape their future must invest in training young people. With some 45 trainees and apprentices employed in commercial or technical jobs, Hosokawa Alpine has one of the highest training quotas in the Augsburg region.

The high quality of the training is reflected time and again by the top marks of the Hosokawa Alpine trainees and apprentices in their final examinations.

Students of the University of Augsburg and other universities are also given support by Hosokawa Alpine in the form of a practical training period or during their dissertation. It is not unusual that this initial contact leads to a permanent job within the company for the trainees and diploma programme students.

(continued)

Photo:

Alpine's trainees in 2006 together with their trainers

Attachments

■

Hosokawa Alpine Aktiengesellschaft

(continued)

Visitors from Around the World at Hosokawa Alpine in Augsburg

Hosokawa Alpine's machines and systems are in demand throughout the entire world. Some 15% of all sales are achieved in Germany, 50% with customers within Europe and the remaining 35% in countries outside Europe. Not only do Hosokawa Alpine engineers, sales personnel and technical specialists travel to their customers around the world, but the customers also come to Augsburg from all four corners of the earth.

They come to attend trials in the testing centre, for discussions and negotiations, or for acceptance tests prior to delivery of their systems. There are many days when a variety of national flags are hoisted on Hosokawa Alpine's plant site in Göggingen to greet the international visitors.

For further information, please visit:

href="https://edir.bulk-online.com/profile/9537-hosokawa-alpine-aktiengesellschaft.htm" target="blank">https://edir.bulk-online.com/profile...sellschaft.htm

Photo:

National flags are raised to greet international visitors

Attachments

■

Hosokawa Alpine Aktiengesellschaft

ANALYSIS AIR JET SIEVE 200 LS-N

NEW in special antistatic design

Air jet sieving permits simple and fast particle size analysis. Because of this, this method has developed into a standard method worldwide over the last 50 years.

The 200 LS-N analysis air jet sieve is designed to measure the fineness of powders down to 10 µm and belongs in every modern particle size laboratory. To rule out operating errors, the unit works with defined parameters. The result in the form of a particle size distribution based on real mass portions is unequivocal, precise and furthermore reproducible. As a result, the 200 LS-N is an accredited testing unit for the exact determination of the powder fineness.

As the specialist when it comes to the processing of dust-explosive products, Alpine joined forces with customers and test institutes to investigate the handling of products in the laboratory and to draw up a risk analysis for Alpine's own laboratory units. During the course of these measures and subsequent to modification of the relevant accessories, Alpine received the EC Design Test Certificate IBEXU06ATEX1074 X as per 94/9/EG (ATEX) Ex-II 1/-D c T 100°C for its 200 LS-N Air Jet Sieve. This means that the 200 LS-N is also ideal for the particle size analysis of dust-explosive powders.

NEW - 200 LS-N in special antistatic design

As a means of reliably preventing the product in the air jet sieve from becoming electrostatically charged, Hosokawa Alpine now offers two new features. An acrylic glass cover in antistatic design with a surface resistance of ? 106 Ohm is now a standard feature of every air jet sieve.

This special design is additionally equipped with an active high-voltage ioniser. This comprises two components: a high-voltage power pack and the actual ioniser itself integrated into an adapter ring. With two rod electrodes arranged direct in the product zone of the air jet sieve, the discharge takes place at the next available point. This saves the complicated addition of sieving aids and takes place – as it were automatically – during every normal sieving process.

For further information, please contact:

href="https://edir.bulk-online.com/profile/9537-hosokawa-alpine-aktiengesellschaft.htm" target="blank">https://edir.bulk-online.com/profile...sellschaft.htm

Photo:

Alpine air jet sieve 200 LS-N

Attachments

hosokawa_alpine_air_jet_sie (JPG)

■

Hosokawa Alpine Aktiengesellschaft

ALPINE POWER BEADS

Ceramic grinding beads in Alpine quality

In accordance with our principle of being a single-source partner, we have extended our range with immediate effect to include grinding beads. The ALPINE POWER BEADS are available in the variants YSZ (zirconia, partly stabilised with yttrium oxide) and SZS (zirconium silicate, sintered), in sizes from 0.1 mm to 2.5 mm ex Augsburg warehouse.

YSZ Power Beads are made of a high-grade zirconia raw material in the nanometre range. This material guarantees excellent mechanical properties, high wear resistance and good corrosion resistance. The use of these grinding beads ensures maximum grinding results at minimum product contamination rates.

SZS Power Beads are manufactured from a zirconia/silica ceramic blend in a special sintering process. Because of the high bulk density and the advantageous price, these grinding beads are particularly suitable for use in large-volume industrial-scale agitated ball mills.

The mechanical properties of Alpine's Power Beads are synchronised to suit operation in all known designs of agitated bead mills. The beads are moreover ideal for dry and wet grinding in planetary mills and other centrifugal mills. The grinding beads increase the electric power introduced into the grinding process due to their high material density, are characterised by a minimum degree of wear and high degree of roundness, and are convincing in their extremely favourable price-performance ratio. The performance of the Power Beads is at its maximum when used with the Alpine agitated bead mills AHM, ANR and DPP. Because these grinding beads are also destined for use in Alpine's testing centre, our consulting service will in future also include definition of the size and construction material of the grinding beads.

For further information, please contact:

href="https://edir.bulk-online.com/profile/9537-hosokawa-alpine-aktiengesellschaft.htm" target="blank">https://edir.bulk-online.com/profile...sellschaft.htm

Photo:

Alpine power beads

Attachments

hosokawa_alpine_powder_bead (JPG)

■

Hosokawa Alpine Aktiengesellschaft

TURBOPLEX CLASSIFIER 500/4 ATP-NG

Turboplex air classifiers are employed for the ultrafine classification of mineral fillers such as limestone or calcite, dolomite, talc, barite and perlite, as well as in the ceramics industry for classifying quartz, feldspar and kaolin.

The results are ultrafine powders in the d97 < 3 - 20 µm fineness range. The classifier operates without spatter grain over the entire separation range and the integrated coarse material classifier ensures a high yield. Wear-protection elements made of Al2O3 are standard for applications in the ceramics industry.

Alpine multi-wheel classifiers were developed especially for ultrafine classifying operations and are ideally suited for processing mineral powders, metal powders, abrasives and different wax types. As a result of the high throughput rates, the Turboplex multi-wheel classifiers can also be combined with correspondingly large mills.

Besides the first-class classifying performance, the Turboplex multi-wheel classifiers offer numerous engineering and operating advantages, because it is now possible with one single Turboplex multi-wheel classifier to accomplish the fineness and throughput values that were formerly only possible with several small classifiers connected in parallel.

The Turboplex multi-wheel classifier ATP has several horizontally installed classifying wheels of the same diameter which are driven separately. An adjustable, static frequency converter is used for the common speed control. New is a 10% increase to the maximum classifying wheel speed. The classifying wheel can be removed and installed either by means of articulated arms or, with the smaller machine sizes, by means of telescopic rails, and this saves time during maintenance procedures. The classifier head is optimised in terms of vibrations and is characterised by an outstanding smoothness of running. The new and streamlined design makes the machine especially compact. The product is either gravity-fed laterally via an airlock or is fed direct into the stream of classifying air.

Dependent on the product and classifier size, special forms of wear protection are available: all-ceramic (Al2O3) classifying wheels, classifying wheels made of SiC, or steel classifying wheels with a tungsten carbide coating. The product-contact parts of the classifier are lined with PU or ceramic, or with exchangeable steel wear-protection elements with a special alloy welded onto the surface.

The 500/4 ATP-NG classifier achieves a fines yield of d97 = 5 µm at 1.8 t/h. The 630/4 ATP-NG, the next size up, achieves a fines yield of d97 = 7.0 µm at 5.8 t/h, and a 750/4 ATP-NG has a throughput of 11.0 t/h at d97 = 10 µm. For higher fineness values in the range d50 < 1 µm at reduced energy consumption, NG classifying wheels with smaller diameters are used. The advantages of the "New Generation" classifying wheel in the form of low energy consumption and high yields are especially conspicuous when used in the submicron range. On average, it was possible to reduce the pressure drop of the NG classifying wheel in comparison with the ATP standard classifying wheel by approx. 60%.

With the new classifying wheel generation, fineness values can be achieved which were formerly inconceivable in production-scale machines. In combination with new mills such as the Hosokawa Alpine ball mill S.O.-SF or the agitated bead mill ATR, fineness values of d50 = 0.5 µm are possible.

Whereas when manufacturing ultrafine fillers, it is the fineness of the classification that is decisive, other applications aim at manufacturing a coarse material with the steepest possible particle size distribution as the end product The NG classifying wheels have also proved themselves to be excellent for this application.

For further information, please contact:

href="https://edir.bulk-online.com/profile/9537-hosokawa-alpine-aktiengesellschaft.htm" target="blank">https://edir.bulk-online.com/profile...sellschaft.htm

Photo:

Turboplex air classifier

Attachments

hosokawa_alpine_turboflex_c (JPG)

■

Hosokawa Alpine Aktiengesellschaft

ALPINE SETS THE TONE WHEN IT COMES

TO MANUFACTURING TONER

The toner used in photocopiers and laser printers usually has a d50 particle size in the range between 5.5 and 10 µm. At the same time, the powder portion < 2 µm must be kept as low as possible.

Besides this, the latest toner types frequently have a low melting point which must not be exceeded during the production process. Hosokawa Alpine has developed a special product range which is tailored to exactly this problem specification, comprising the TFG fluidised bed toner mill and the TSP and TTSP ultrafine classifiers. These machines often also form the heart of systems which operate in accordance with Alpine's toner production process.

In the case of the demanded particle sizes, the TFG fluidised bed opposed jet mill for toner has a considerable energy advantage and a sharp top-size limitation. Even toner types with a high content of iron oxide are processed almost completely without iron contamination. The product line is characterised by its ease of cleaning and is designed for frequent product changes.

It is unavoidable that undesirable fine dust develops during the manufacture of toner. The TSP and TTSP ultrafine classifiers are used to separate and filter out this fine dust (< 3 to 5 µm). The extremely high precision of cut of the TTSP tandem classifier guarantees top-quality, dust-free end products at optimum product yields.

Every manufacturer of photocopiers and printers uses toner with a very specific chemical composition and formulation. Determination of the optimum machine parameters for comminution and classification takes place in Hosokawa Alpine's own testing centre. Based on these test results, Hosokawa Alpine can offer the customer a wide range of solutions – from the single machine right up to a turnkey system.

Hosokawa Alpine has over 20 years of experience in the technology of toner manufacture. Leading toner powder producers the world over rely on our equipment. These systems have reached an extremely high market penetration, and a major share of the toner manufactured worldwide is produced with our machines. The machines and systems are available in a number of different sizes and thus cover every performance demand – from laboratory to production-scale applications.

For further information, please contact:

href="https://edir.bulk-online.com/profile/9537-hosokawa-alpine-aktiengesellschaft.htm" target="blank">https://edir.bulk-online.com/profile...sellschaft.htm

Photo:

200 TTSP two-stage toner classifier

Attachments

hosokawa_alpine_toner_produ (JPG)

■

Hosokawa Alpine Aktiengesellschaft

PROCESSING OF SODIUM BICARBONATE

the perfect application for classifier mills APP

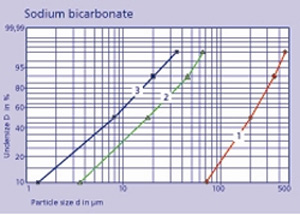

New laws and more stringent limit values are forcing numerous operators of waste incineration plants to seek the most cost-effective methods possible of cleaning the flue gases. The performance of sodium bicarbonate when used for cleaning flue gas has proved excellent. Especially when rubbish, old tyres or other critical substances are burnt, sodium bicarbonate achieves outstanding cleaning effects. Approximately 99% of the hydrochloric acid (HCl) and 95% of the sulphur dioxide (SO2) is removed. To this end, finely ground sodium bicarbonate in the range d90 = 20 µm to d90 = 45 µm is needed. For this application, Alpine classifier mills APP have proved themselves in operation.

The amount of sodium bicarbonate that is necessary for a certain cleaning effect can fluctuate. The basic prerequisite, however, is that the d90 value of the ground product remains as constant as possible. The particle size distributions shown below were achieved during test runs with the 160 APP. The particle size distributions remained constant over the entire duration of the 8-hour test. The constant product parameters of the ground sodium bicarbonate make it possible for the system operator to supply exactly that amount of sodium bicarbonate necessary for the contaminant concentration, meaning that consumption can be reduced to a minimum.

(continued)

Photo:

Powderplex classifier mill 160 APP

Attachments

hosokawa_alpine_powderflex_ (JPG)

■

Hosokawa Alpine Aktiengesellschaft

(continued)

Operational capacity of the 160 APP test machine:

Curve 1Feed: < 500 µm

Curve 2d90 = 45 µm250 - 280 kg/h

Curve 3d90 = 20 µm130 - 140 kg/h

Besides their excellent suitability for fine-grinding sodium bicarbonate, the APP mills are characterised by their simple design and extremely robust construction. The modular design permits easy access for cleaning and maintenance. Dependent on the fineness and machine size, the performance range of the APP product line when grinding sodium bicarbonate is 140 kg/h to 1100 kg/h.

For further information, please visit:

href="https://edir.bulk-online.com/profile/9537-hosokawa-alpine-aktiengesellschaft.htm" target="blank">https://edir.bulk-online.com/profile...sellschaft.htm

Attachments

hosokawa_alpine_sodium_bica (JPG)

■

Hosokawa Alpine Aktiengesellschaft

PROCESS TECHNOLOGY AND ISOLATOR

CONTAINMENT SYSTEMS FROM ONE SOURCE

In the last years, the trend towards isolator technology has increased in the pharmaceuticals industry. In the case of process-technological applications such as the comminution or compaction of powders, protecting the operating personnel from active substances is a top priority and the isolators used in this case are often also called containment systems. With products such as antibiotics, an additional demand is for aseptic manufacture in a sterile system.

Experience has shown that every isolator needs to be adapted to suit not only the specific demands of a pharmaceutical product and its manufacturing process, but also the product blend to be processed, the batch size and also the technical environment that prevails in the production building.

Prior to manufacture of the machine, a mock-up is made to determine the optimum position of process-technological components, glove openings and transfer systems, and is subsequently optimised in close collaboration with the customer. The operator must be able to reach all relevant points via the glove openings. In preparation of production, machine components must be selected whose size and weight makes them suitable for installation via a transfer system. The machine components that need to be fitted must permit simple assembly – where possible without tools. And at the end of a production batch, the system must be cleaned or decontaminated. Independent of the product to be processed, WIP, CIP and SIP systems can all be realised.

Hosokawa Alpine offers the pharmaceuticals industry everything that is necessary for an isolator project from the one single source: process-technological trials, engineering of the isolator and equipment, plus documentation and validation. The customer thus saves the time- and cost-intensive coordination of interfaces and project plans from the different manufacturers of subassemblies. Over and above this, the customer profits from the wealth of experience continuously gathered by Hosokawa Alpine over the years. This total competence constitutes a substantial value increase for the customer company. It is therefore no more than a logical consequence that the orders for Hosokawa Alpine isolators have increased steadily over the past years

For further information, please visit:

[url]https://edir.bulk-online.com/profile/9537-hosokawa-alpine-aktiengesellschaft.htm[/

url]

Photo:

Complete grinding process including product handling

in a 3-chamber isolator with 100 UPZ fine impact mill

Attachments

hosokawa_alpine_isolator_co (JPG)

■

Hosokawa Alpine Aktiengesellschaft

COST-EFFECTIVE PROCESSES FOR THE MANUFACTURE OF

PROTEIN CONCENTRATES FOR INDUSTRY

For years, animal meal was the major protein supplier for industrial applications. As a result of new legislation, animal meal will now be replaced by vegetable proteins. If, however, the animal protein is to be replaced by vegetable protein, an almost 20% higher requirement must be reckoned with. In the case of soya grits, that would mean an annual total demand of 21 million tonnes. The main suppliers of soya are the USA and Brazil. Because on the one hand, the industry within the EU wants to make itself independent of the oligopolistic soya market, and on the other hand, the agricultural industry is looking for new and efficient utilisation possibilities for arable cropland, leguminous plants such as beans and peas are absolutely ideal as modern protein suppliers. In contrast to soya, these leguminous plants also contain starch as energy suppliers in addition to the valuable protein.

Alpine grinding and classifying systems have been in successful operation for decades for processing cereal products such as wheat or corn and leguminous plants such as peas, beans, lupines and soya. The actual process ranges from the raw material decortication and fine grinding to the separation of specific constituents in an air classifier. The technology focuses on protein enrichment or depletion by means of mechanical processing. The fundamental principle bases on employing fine grinding to disintegrate the shell-free endosperm.

After the fine grinding process, the grain constituents – mainly protein and starch – are liberated. This bulk material is fed to a deflector-wheel air classifier which generates two fractions: a protein-enriched and a protein-depleted product.

We offer 2 process solutions for the cost-efficient processing of leguminous plants:

1. STANDARD PROCESS

Low energy requirement – high yield.

Fines portionProtein content

Peas (yellow)30%> 50%

Beans (broad beans)25 - 30%> 65%

SPC (soya protein concentrate)> 60%> 65%

Raw material is soya meal with approx. 55 to 60% protein.

(continued)

Photo:

Contraplex 800 CW pin mill (for wheat flour)

Attachments

hosokawa_alpine_protein_shi (JPG)

■

Hosokawa Alpine Aktiengesellschaft

(continued)

2. HIGH-PRECISION PROCESS

Maximum yield – maximum quality.

Fines portionProtein content

Peas (yellow)****************35%>************55%

Beans (broad beans)**> 35%>************65%

Lupines*********************> 40%>************60%

All-important for selection of the optimal process solution is your individual problem specification: the objective is either maximum protein enrichment, i.e. > 55%, or maximum protein depletion, i.e. a protein content of < 10%.

Under application of the high-precision process, you are always in a position to react flexibly to market demands, both with respect to maximum protein enrichment, e.g. > 55% as a substitute for animal meal as well as maximum protein depletion, e.g. < 8% for use in the plastic film and starch industries.

The systems amortise in this way very quickly and justify the investment made in the purchase price and operating costs.

For further information, please visit:

href="https://edir.bulk-online.com/profile/9537-hosokawa-alpine-aktiengesellschaft.htm" target="blank">https://edir.bulk-online.com/profile...sellschaft.htm

Photo:

System with Zirkoplex ZPS classifier mill and

Turboplex ATP classifier (precision process)

Attachments

hosokawa_alpine_zirkoplex_c (JPG)

■

Hosokawa Alpine Handbook

Hosokawa Alpine Handbook

WEALTH OF KNOW-HOW AND

EXPERIENCE FOR COMPLETE PROCESS SOLUTIONS

New Edition of "Powder and Particle Processing" Handbook

Hosokawa Alpine, the leading company when it comes to machines and systems for processing fine powders, has released a revised and completely updated version of its "Powder and Particle Processing" handbook first published in 1991. Over a total of 270 pages, the handbook gives process engineers and engineers from all walks of industry the opportunity of informing themselves about cost-effective solutions at an early stage of production planning.

After an introduction devoted to the over 100-year-old Augsburg company, the first part of the handbook is dedicated to the vast range of process solutions available for the chemicals, minerals, metals, pharmaceuticals, food and recycling sectors. With the help of numerous real-life examples, job specifications are described and complete solutions are presented. The specialist will find all the relevant performance data for his particular process-technological project.

In the second part, the system components engineered and manufactured by Alpine in Germany are presented, and their operating principles, applications and features are addressed. The individual modules of the process-specific automation technology by Hosokawa Alpine are also described, and one section is dedicated to particle design and the systems for producing new types of functional materials in the nanometre range. The informative compendium is augmented by a wealth of technical information and is rounded off by a description of the services offered by Alpine, which range from consultancy and engineering, trials and project planning to commissioning, training and maintenance.

The handbook can be ordered in Internet (

href="http://www.alpinehosokawa.com/engl/manual.htm" target="blank">http://www.alpinehosokawa.com/engl/manual.htm) for € 25 (incl. VAT and delivery within Europe) and for € 25 plus € 12 (incl. VAT and delivery outside Europe). There may be duties and taxes imposed on your order that are not reflected in our prices.

More more details on Hosokawa Alpine, please visit:

href="https://edir.bulk-online.com/profile/9537-hosokawa-alpine-aktiengesellschaft.htm" target="blank">https://edir.bulk-online.com/profile...sellschaft.htm

Attachments

■

Hosokawa Alpine AG

Hosokawa Alpine Aktiengesellschaft – which many customers, employees and numerous residents of Augsburg simply call "Alpine" – has experienced continual economic growth ever since the company was founded 100 years ago, and has also demonstrated quite impressively that it is possible to master even the most difficult times with constant innovation and flexibility.

The trade name ALPINE acquired an excellent reputation in industry as early as the first half of the 20th century. And up to this day, Alpine – which celebrated its 100-year anniversary in 1998 – stands for state-of-the-art technology in leading-edge quality. Thanks to the confidence of customers all over the world, Hosokawa Alpine's two divisions "Powder and Particle Processing" and "Blown Film Processing" are leaders in their respective fields.

(continued on next post)

Photo:

Film extrusion system for the manufacture of 3-layer film

Attachments

hosokawa_alpine_1a (JPG)

■