Saving Energy In Cement Plants (Continued)

The question to be answered was: Is there a metering system available for this plant section which also closes the free passage to the drier? We were optimistic right from the beginning that a modification of our clearing rotary valve (Photo 2), which is a tried and tested system for other applications, would be capable of coping with the task.

Additional benefits would be the reduction of the harmful CO2 exhaust gas and a lower noise level.

Following the commissioning of the rotary valve, accurate measurements will be made to document the amount of energy actually saved. Recent calculations made together with the customer resulted in an annual saving of approx. 1,500 – 3,000 kWh or 50.000 litres of fuel oil.

The newly developed technology can also be used for applications in which the raw material is dried directly in the cement mill. The latest KREISEL development can even be used for conveying wet and sticky material or bulk material which is difficult to feed because of seasonal conditions (rain, frost). The obvious advantage is a considerable potential for reducing the load on the environment. In order to make use of this positive development also in future, KREISEL built a new production hall and put it into operation at the end of 2006.

For more information, please visit:

href="https://edir.bulk-online.com/profile/2238-kreisel.htm" target="blank">https://edir.bulk-online.com/profile/2238-kreisel.htm

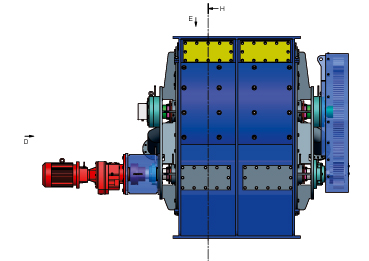

Photo 2:

Clearing rotary valve

Attachments

■

Energy in Cement Plants

Saving Energy in Cement Plants

KREISEL have been supplying the cement industry with bulk material feeding equipment for many years.

At a Polish cement plant, the raw material (approx. 400 t/h) is currently fed on a conveyor belt into the crusher/drier in a fall shaft that is open at the top. Because of this open shaft, the heat generated in the process (approx. 550 °C) gets lost. The pressure loss related thereto causes noise nuisance reaching a noise level of up to 130 dB(A). (Photo 1).

(continued on next post)

Photo 1:

Partial view of the cement plant

Attachments

kreisel_1_1 (JPG)

■